Datasheet

SONARANGE UPF-A 08.13 e

This Information corresponds to the current state of knowledge. SNT reserves the right to make technical changes. Do not use these products in any application

where failure of the product could result in personal injury. Liability for consequential damage resulting from the use of SNT products is excluded.

SNT Sensortechnik AG, Hammerstrasse 6, CH-8180 Bülach, Switzerland, Phone +41 44 817 29 22, Fax +41 44 817 10 83, info@sntag.ch 3/4

www.sntag.ch

Teach-In with keyboard

Status A (material is fully introduced): push key A for

min. 2s until yellow LED near A blinks 3x

(acknowledgment by lighting of all 3 LEDs)

Status B (no material in fork): push key B for min. 2s

until yellow LED near B blinks 3x (acknowledgment by

lighting of all 3 LEDs)

Inverting the signal: push both keys A and B

simultaneously for min. 5s until yellow LED near A lights

up. Then release keys. Acknowledgment by lighting of

all 3 LEDs. Reverse the inverting by the same

procedure.

Factory reset: push both keys A and B simultaneously

for 10s until green LED lights up. Then release keys.

Acknowledgment by lighting of all 3 LEDs.

Key lock: push both keys A and B simultaneously for

15s until yellow LED near B lights up. Then release

keys. Acknowledgment by lighting of all 3 LEDs. Unlock

the keys in the same way.

Teach-In by the connector

Pin 2 of the connector has besides the function for

synchronization also the same teach function as Key B. The

adjustment of the max. signal output at fully open fork can

therefore also be done by connecting pin 4 with power supply

voltage (nom. 24VDC) during min. 2s. Subsequently, the pin

2 must be removed from the tension.

The sensor can e.g. be operated after teaching with a 3 wire

cable as well. Teach via connector is possible also if the key

lock is enabled.

Synchronization

The internal sampling clock of the sensor can be overcome

with an external repeating signal. This can be helpful if

several sensors are measuring along a fast moving web.

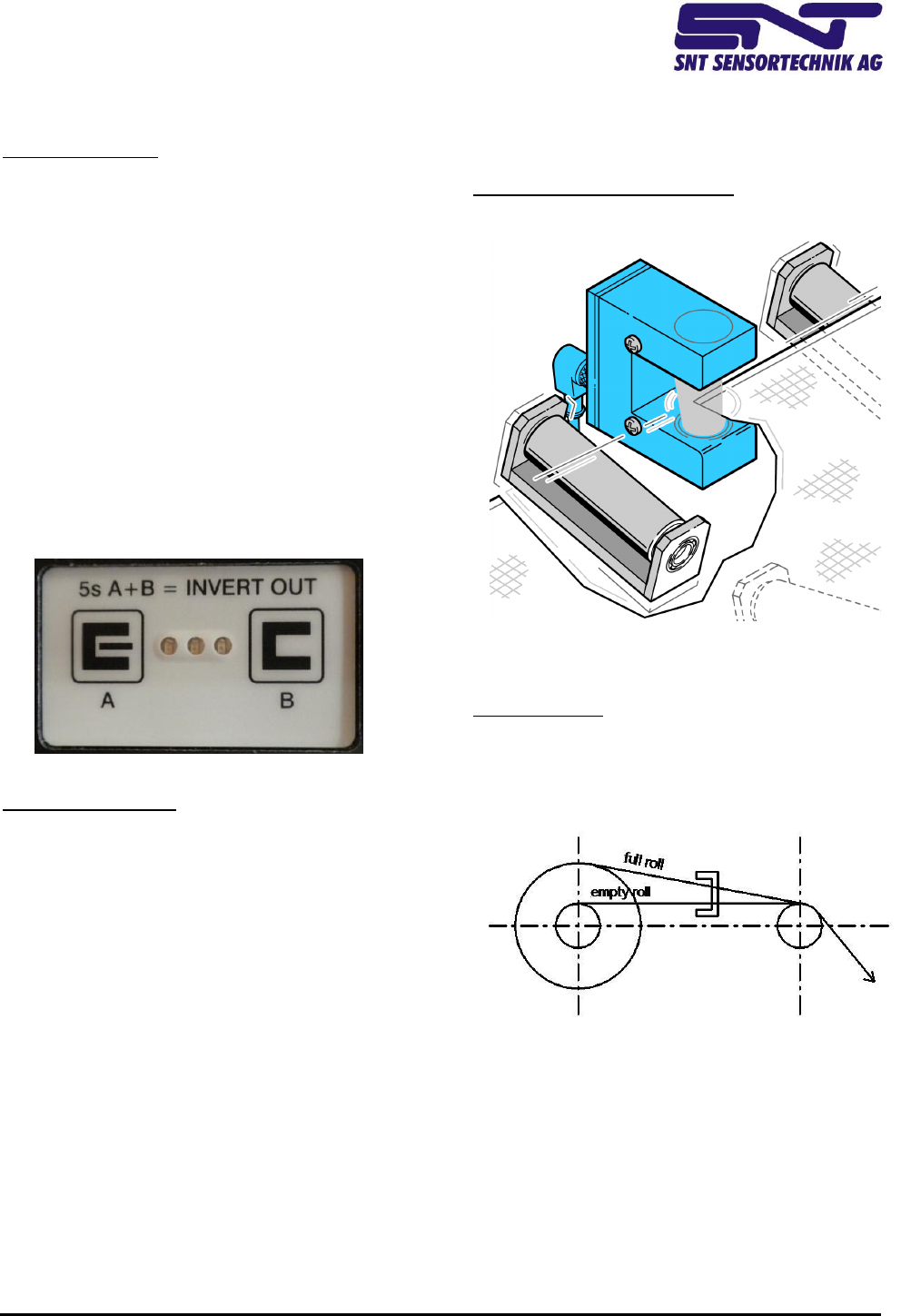

Application

Measurement of the web edge position:

Various fork widths:

Larger fork widths are of particular interest if the material web

is vertically heavily flattering or if it does not always pass at

the same position during unroll or roll up (see picture below).