Datasheet

SONARANGE UPF-A 08.13 e

This Information corresponds to the current state of knowledge. SNT reserves the right to make technical changes. Do not use these products in any application

where failure of the product could result in personal injury. Liability for consequential damage resulting from the use of SNT products is excluded.

SNT Sensortechnik AG, Hammerstrasse 6, CH-8180 Bülach, Switzerland, Phone +41 44 817 29 22, Fax +41 44 817 10 83, info@sntag.ch 2/4

www.sntag.ch

Electrical connection

-

M12 connector, 4-pin

Mass

g

200

220

360

400

Properties

The edge sensors type UPF-A are based on the experience

of SNT Sensortechnik AG with ultrasonic through beam

sensors. New software algorithms and a unique SONARANGE

ultrasonic transducer material allow an accuracy and

temperature stability so far only realized with optical systems.

But the ultrasonic fork barrier is much less sensitive to dirt

and dust compared to optical sensors. Further more

transparent materials such as foils can be perfectly handled.

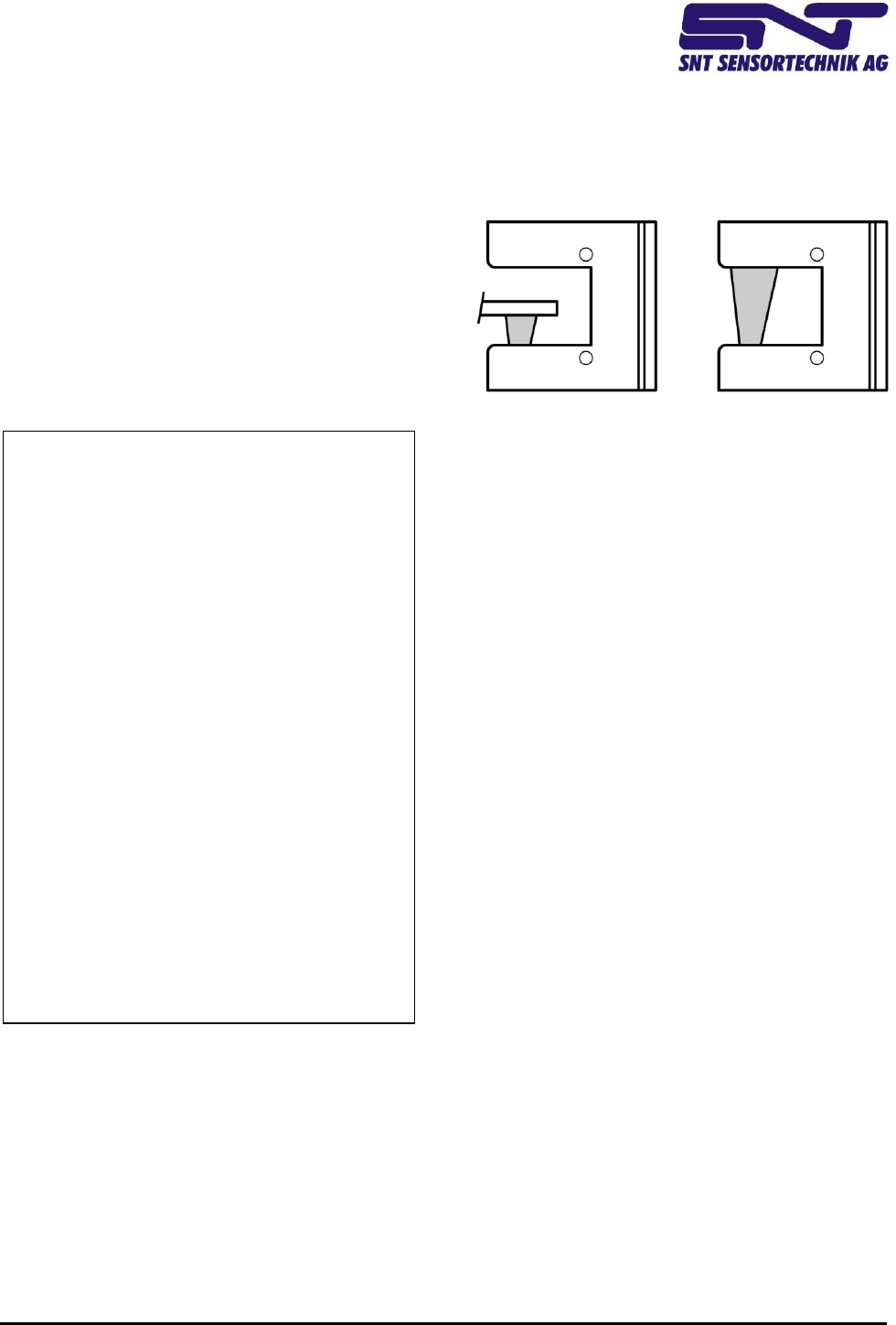

The UPF-A are ultrasonic through beam sensors with

separated transmitter and receiver. They are suited for edge

detection on web guiding systems. In contrast to

conventional barriers they do not offer a simple on/off output

signal, but they measure the degree of covering of the

ultrasonic receiver as an analogue output signal. If the

receiver is fully covered, the output is 0V and if not covered

at all 10V or vice versa.

Status A: 0V Status B: 10V

(or 10V inverted) (or 0V inverted)

The relative humidity of air and the air pressure as well (sea

level) have an influence on the output signal due to physical

laws (attenuation of sound). Higher air humidity or

decreasing air pressure do reduce the output signal at a

given edge position.

Sea level: for 100m higher sea level approx. 1.6% signal

reduction

Air pressure: for 10mbar pressure increase approx.

1.3% signal increase

Air humidity: for 10% higher rel. air humidity approx.

1.2% signal reduction

The sensor can ideally be adjusted to the actual air

conditions by the help of the teach-in function.

Teach-In

With teach-in the signal output can be defined at fully closed

fork (status A) as well as at fully open fork (status B).

Status A: If an acoustically non transparent material is in

the fork, no signal is recorded by the receiver and thus

the sensor shows 0V. However if the material is partly

acoustically transparent (e.g. textiles), the sensor would

show an offset. By teaching this status the offset can be

eliminated and the full 10V span is available. For

teaching the status A the material must be fully

introduced into the fork.

Status B: If nothing is between transmitter and receiver,

the sensor should show the full signal of 10V. As

explained above, the signal can slightly vary depending

on air conditions. By teaching this status the full range

signal can be adjusted to exactly 10V. For teaching the

status B the fork must be fully free of material.

In addition, the output signal can also be inverted via teach-

in, i.e. either rising or falling signal with increasing coverage

of the sensor.

The 5 advantages of SNT ultrasonic fork sensors

1. The SNT ultrasonic transducers have a large

diameter.

Result: large measurement range combined with

high linearity and resolution.

2. The all new SONARANGE material of the ultrasonic

transducers has a Young’s modulus which is

constant up to higher temperatures compared to

the past.

Result: high temperature stability.

3. The signals are compensated with computed data

as well as with a temperature sensor.

Result: precise operation up to 60°C.

4. The sensors have the teach-in feature.

Result: They can be adapted to the actual air

condition and the material.

5. Software and transducers are designed to

eliminate the influence of multiple echoes.

Result: Very small influence of plane change and

high measuring speed.