Manual

Starting the engine

From the lower controls

1. Turn the chassis key switch to chassis position.

2. Press the start button to crank the engine.

Release when the engine starts.

3. When the engine is cold: press and hold the

choke button while starting gasoline / propane

engines; press and hold the glow plug button for

six seconds prior to starting diesel engines.

From the platform controls

1. Turn the chassis key switch to platform controls.

2. Turn the platform keyswitch fully clockwise to

crank the engine. Release when engine starts.

3. When the engine is cold: Press and hold the

choke button while starting gasoline / propane

engines. Press and hold the glow plug button for

six seconds prior to starting the diesel engine.

Driving

With Boom Lowered

1.

Turn chassis key switch to platform, and turn on (turn

clockwise) the chassis emergency stop switch.

2. Mount the platform, close and latch the gate.

3. Attach approved fall restraint to designated

platform anchorage point. Attach only one fall

restraint to each point.

4. Start engine.

5. Check that the area around and above the work

platform is clear of obstructions, holes, drop-offs,

persons in the route of travel, and the surface is

capable of supporting wheel loads.

6. Depress the foot switch and move the drive

control handle forward to travel forward and

reverse to travel in the reverse direction.

7. While driving, press the differential lock button,

located on the front of the drive control handle,

as necessary for improved traction.

Note: When the boom is rotated to the front of

the chassis (steering wheels aft) directions of

travel and steering will be reversed. Observe the

color coded arrows on the control panel near the

drive control handle, and on the chassis. They

will indicate the direction of travel when the drive

control handle is moved.

With Boom Elevated

Travel with boom elevated is restricted to firm

level surfaces only.

When driving elevated, the machine will travel at

creep speed (1/2 foot [.15 m] per second).

Steering

1. While depressing the foot switch, push the steer-

ing switch (located on top of the control handle) to

the left to turn left, and right to turn right.

Note: Steering is not self centering. Wheels

must be returned to the straight ahead position

by operating the steering switch.

POSITIONING THE PLATFORM

Positioning the platform as close as possible to the

work area requires some planning. First, you must

survey the work site to find a suitable place to park

the machine. This must be a firm level area as

close as possible to the work area. Take into

consideration all obstructions on the ground and

overhead and avoid them.

Once you have moved the machine to a firm level

surface as near as possible to the work area, follow

the instructions on page five to position the platform

as close to the work area as possible.

Always, before operating any function, check the

area around and overhead for any obstructions or

electrical conductors.

NEVER exit the platform while the boom is

elevated. Keep both feet firmly planted on

the platform floor at all times.

Multifunction Controls

The UpRight AB-46 employs the use of multifunction

controls. This means that riser or boom extension

will function at full speed while simultaneously

operating upper boom, jib, turret, or rotating the

platform.

The turret may be rotated while driving if necessary

to make turns in tight areas. All other boom func-

tions will not operate while driving.

Lower Control Operation

All boom functions will operate at fixed speed.

1. Turn chassis keyswitch to chassis controls.

2. With engine running, operate boom control

switches to position the platform.

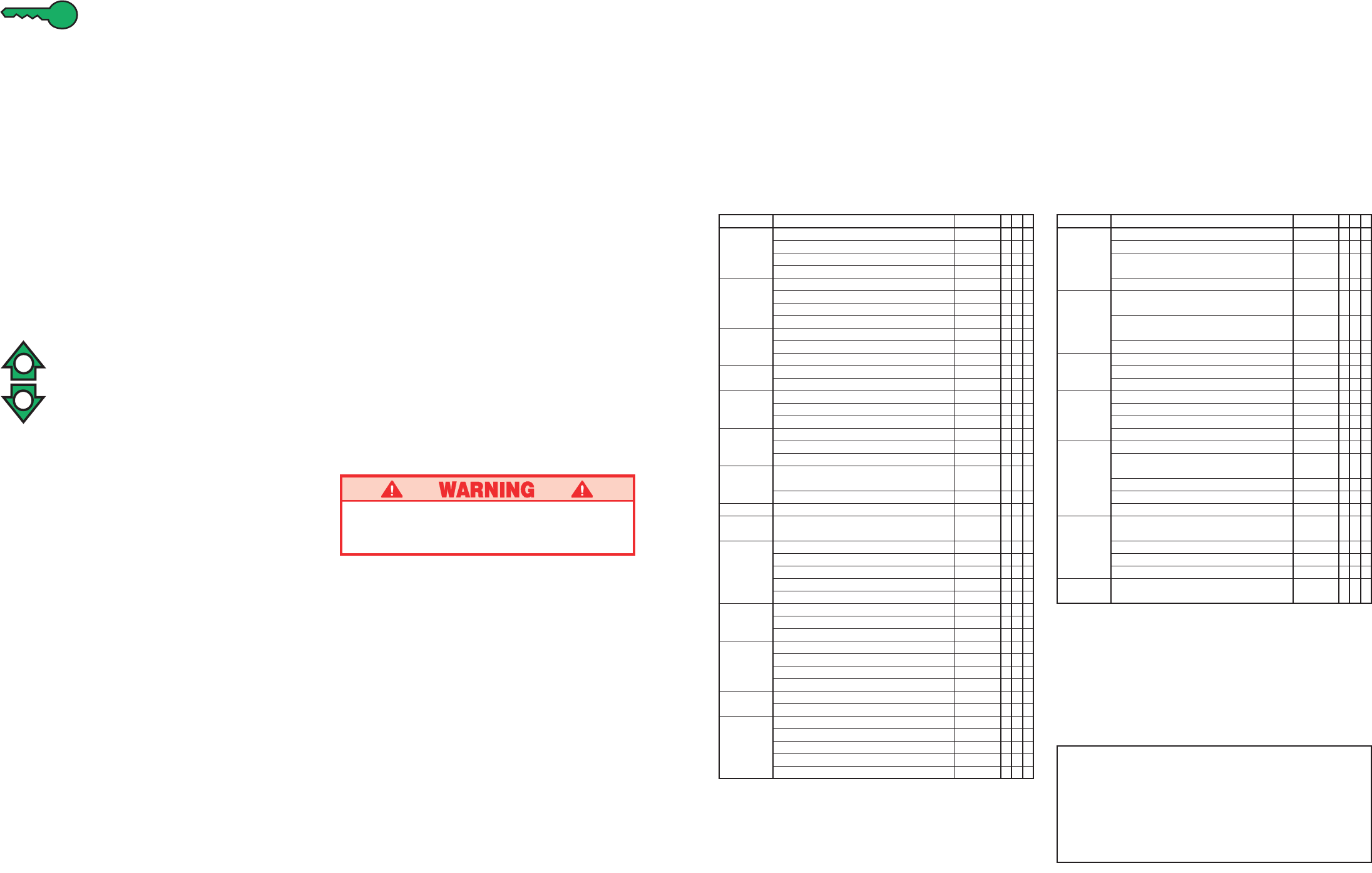

Routine Service Table Key

Interval

Daily=each shift (every day) or every eight hours

30

D

=every month (30 days) or every 50 hours

3

M

=every 3 months or 125 hours

6

M

=every 6 months or 250 hours

1

Y

=every year or 500 hours

2

Y

=every 2 years or 1000 hours

Y=Yes/Acceptable

N=No/Not Acceptable

R=Repaired/Acceptable

Routine Service Table

Service Report

Date: _______________

Owner: _________________________________

Model No: ____________ Serial No: __________

Serviced By: _____________________________

Service Interval: __________________________

COMPONENT INSPECTION OR SERVICES INTERVAL Y N R

Elevating Inspect for structural cracks Daily

Assembly Check pivot points for wear 30

D

Check pivot pin retaining bolts 30

D

for proper torque

Check members for deformation Daily

Chassis Check hoses for pinch or Daily

rubbing points

Check component mounting 6

M

for proper torque

Check welds for cracks Daily

Turret Check ring gear for proper lubrication and wear Daily

Lubricate worm gear bearings 150

H

/3

M

Lubricate ring gear (MoS

2

grease) 150

H

/3

M

Torque Check for leaks Daily

Hubs Check oil level 250

H

/6

M

Change oil after break-in period 50

H

/30

D

Change oil (SAE 90 wt. gear oil) 2000

H

/2

Y

Lift Check the cylinder rods for wear 30

D

Cylinders Check pivot pin retaining bolts 30

D

for proper torque

Check seals for leaks 30

D

Inspect pivot points for wear 30

D

Check fittings for proper torque 30

D

Entire Check for and repair Daily

Unit collision damage

Check fasteners for proper torque 3

M

Check for corrosion, remove and repaint 3

M

Lubricate 30

D

Labels Check for peeling, missing, or unreadable Daily

labels & replace

ROUTINE SERVICE

Use the following table as a guide for routine main-

tenance. Inspection and maintenance shall be

performed by personnel who are trained and

familiar with mechanical and electrical proce-

dures. Refer to the Service Manual for complete

service instructions.

Please copy this page and use the Routine Service

Table as a checklist when inspecting a machine for

service.

COMPONENT INSPECTION OR SERVICES INTERVAL Y N R

Engine Oil Check level and condition Daily

Check for leaks Daily

Change oil & filter (Dual Fuel) 3

M

Change oil & filter (Diesel) 100

HOURS

Engine Fuel Check fuel level Daily

System Check for leaks Daily

Replace fuel filter 6

M

Check air cleaner Daily

Battery Check electrolyte level Daily

Clean exterior 3

M

Clean terminals 3

M

Engine Check coolant level (with engine cold) Daily

Coolant Replace coolant 3

M

Hydraulic Check oil level Daily

Oil Change filter 6

M

Drain and replace with ISO 46 compatible oil 2

Y

Hydraulic Check for leaks Daily

System Check hose connections 30

D

Check hoses for exterior wear 30

D

Emergency Check operation of emergency override Daily

Hydraulic valves and hand pump

System Check operation of brake release hand pump Daily

Controller Check operation of all controls Daily

Control Check the exterior of the cable Daily

Cable for pinching, binding or wear

Platform Check fasteners for proper torque Daily

Floor and Check welds for cracks Daily

Rails Check condition of platform Daily

Check condition of anchorage points Daily

Check condition of operators manual Daily

Tires Check for damage Daily

Check air pressure (65 psi) Daily

Check lug nuts (torque to 90 ft. lbs. [123 Nm]) 30

D

Hydraulic Wipe clean 30

D

Pump Check for leaks at mating surfaces 30

D

Check for hose fitting leaks Daily

Check mounting bolts for proper torque 30

D

Hydraulic Check hydraulic drive motor operation Daily

Drive System

Check hoses, fittings, and valve block for leaks Daily

Steering Check fittings for proper torque 6

M

System Oil all pivot points 30

D

Check steering cylinder for leaks 30

D

Check linkage for wear areas 30

D

Check for missing / loose retainers Daily

4

9