Use and Care Manual

Table Of Contents

GB - 18

Axle Shaft

Grease the axle gear and oil the axle

bushings (Figure 13).

SCRAPER BLADE

IMPORTANT: Damage to auger/impeller

housing will result if blade wears down too

far.

Scraper blade is adjustable to compensate

for wear.

To adjust scraper blade:

1. Tip unit back onto handlebar, support

housing and loosen nuts retaining blade.

2. Adjust skid shoes to fully raised position

(housing closest to ground).

3. Reposition scraper blade flush with skid

shoes and tighten lock nuts.

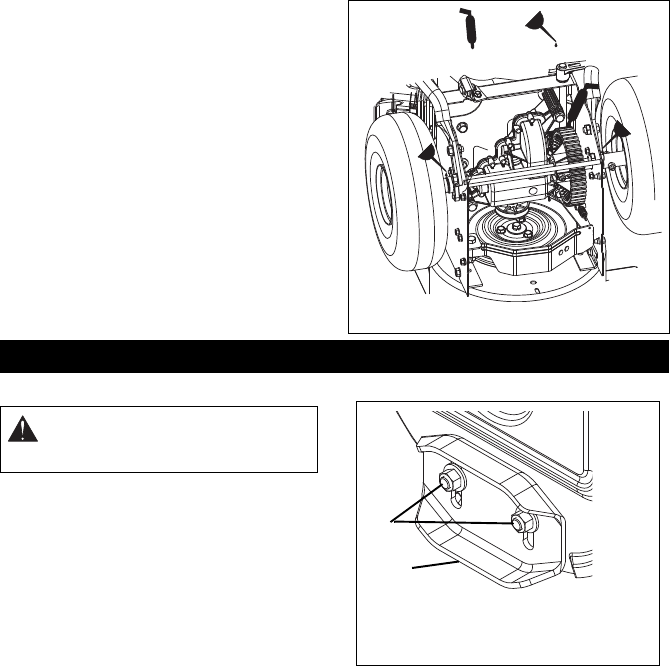

SKID SHOES

Skid shoes should be adjusted as conditions

require (Figure 14).

1. Position unit on a hard, flat, smooth level

surface.

2. Adjust skid shoes by inserting a spacer

of desired thickness under center of

scraper blade, loosen skid shoe

hardware, slide skid shoes to flat

surface. Allow 1/8 in. (3 mm) between

scraper blade and hard smooth

surfaces. Allow 1-1/4 in. (30 mm)

between scraper blade and uneven or

gravel surfaces. Retighten hardware.

NOTE: Keep housing level by adjusting skid

shoes equally.

SHEAR BOLTS

IMPORTANT: Use only Ariens shear bolts for

replacement. Use of any other type of shear

bolt may result in severe damage to unit.

Occasionally a foreign object may enter the

auger/impeller housing and jam the auger,

breaking shear bolts which secure the auger

to the shaft (Figure 15). This allows auger to

turn freely on the shaft which may help

prevent damage to gear case and its

components.

For Replacement:

1. Align shear bolt holes in auger with

shear bolt holes in the shaft.

2. Drive shear bolt through hole (if shear

bolt was broken this will drive remaining

part from shaft).

3. Secure shear bolt with nut.

NOTE: DO NOT overtighten the shear bolt.

Tighten shear bolt to 5.8 – 12.2 lbf-ft

(7.9 – 16.5 N•m).

Grease

Oil

Figure 13

SERVICE AND ADJUSTMENTS

WARNING: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

Figure 14

2

1

OS0750

1. Skid Shoe

2. Skid Shoe Hardware