Manual

Table Of Contents

- 1 General instructions

- 2 Safety regulations

- 3 Product description

- 4 Transporting the pistol

- 5 Handling the pistol

- 5.1 General remarks

- 5.2 Initial preparation

- 5.3 Ammunition

- 5.4 Loading the magazine

- 1. Place round on feeder 53, close to the magazine lips.

- 2. Press round down and push it to the rear.

- 3. Load the number of rounds that you intend to shoot.

- 5.5 Loading the pistol (ready to fire)

- Procedure:

- Procedure:

- 1. Aim the pistol at a safe target.

- 2. Place finger on trigger and pull back the trigger to discharge the shot.

- 3. Keep the pistol aimed at the target and fire further shots as required.

- 4. Remove magazine and unload the pistol (see Section 5.8). If the pistol has been fired until the magazine is empty, slide 4 will be caught in the open position. If firing is to continue, reload the pistol (see Section 5.7).

- 5.7 Reloading during shooting

- 5.8 Unloading the pistol

- 5.8.1 Unloading the pistol, magazine not empty

- 1. Keep the muzzle of the pistol pointed in a safe direction.

- 2. For Double Action/Single Action pistols: Press decocking lever 40 down, the hammer 29 catches in the safety intercept notch. With Double-Action-Only pistols, hammer 29C automatically registers in the safety intercept notch.

- 3. Press magazine catch 43 down and remove magazine (see Fig. 2).

- 4. Draw back slide 4 to the stop and arrest it in the open position. The round is ejected.

- 5. Check visually and manually with a tool that the round was ejected and that no other round is chambered (see Fig. 3).

- 6. Release slide 4. The slide 4 is impelled forward.

- 7. Press decocking lever 40 down (not applicable to DAO pistols).

- 8. Empty magazine.

- 9. Pick up and clean ejected round.

- 5.8.1 Unloading the pistol, magazine not empty

- 5.8.2 Unloading the pistol, magazine empty, slide open

- 1. Keep the muzzle of the pistol pointed in a safe direction.

- 2. Press magazine catch 43 down and remove magazine (see Fig. 2).

- 3. Check visually and manually with a tool that the round was ejected and that no other round is chambered.

- 4. Draw back slide 4 to the stop and allow it to fly forward.

- 5. Press decocking lever 40 down (not applicable to DAO pistols).

- 6. Check the load state of the magazine.

- 6 Sight correction

- 5 Handling the pistol

- 7 Pistol maintenance

- 7.1 Stripping the pistol

- 1. Unload the pistol (see Section 5.8).

- 2. Thumb down takedown lever 16.

- 3. Draw back slide 4 to the stop and arrest it in the open position.

- 4. Check that no round is chambered (see Fig. 3).

- 5. Lift and hold slide 4 in the back and allow it to glide forward.

- 6. Slip slide 4 forward and off the frame.

- 7. Pull recoil spring 3 off the barrel 1.

- 7.2 Disassembly of the magazine

- 7.3 Cleaning the pistol

- 1. Lubricate the cleaning brush with gun oil and insert it into the barrel 1 via the chamber. Use brush to carefully remove all powder residues and dirt in the barrel and chamber.

- 2. Wipe powder residues and oil from the barrel bore and chamber with cleaning patches.

- 3. Clean external surfaces of barrel with a brush dipped in gun oil.

- 4. Remove dirt from metal guide in the frame 15, inside and outside of slide 4 and recoil spring 3 with a brush and cleaning patch and then wipe down with a cloth impregnated with gun oil or gun grease.

- 5. Lightly oil bores of barrel and chamber. Remove any excess lubricant.

- 7.4 Assembling the pistol

- 1. Check that there is no foreign matter inside the pistol.

- 2. Check that serial number, slide number and frame number tally.

- 3. Cock hammer 29 (not applicable to DAO pistols).

- 4. Slide the recoil spring 3 with the smaller diameter on the barrel 1 first.

- 5. Thumb down takedown lever 16.

- 6. Lead slide 4 over the recoil spring 3 and pull over the barrel 1 with slightly lifted end until the rear part.

- 7. Lift the rear part onto the frame 15 and let the slide glide forward with your hand.

- 8. Flip up the takedown lever 16 clockwise.

- 9. Press decocking lever 40 down (Not applicable to DAO pistols).

- 7.5 Verification of functions

- 1. Make sure that the magazine is removed and the pistol unloaded (see Section 5.8).

- 2. Check the elasticity of the recoil spring 3 and the smoothness of the slide 4 (no jamming).

- 3. Check the double-action trigger (DA).

- 4. Check trigger travel and trigger interruption.

- 5. Check simple trigger function (SA). (Not applicable to DAO pistols)

- 6. Check function of decocking lever 40 and safety intercept notch on hammer 29.

- 7. Check slide catch lever 18.

- 8. Inspect magazine.

- 9. Inspect external appearance of the pistol.

- 10. Verification of numbered components.

- 7.6 Care of the pistol

- 8 Pistol service and repairs

- 8.1 Cause and correction of malfunctions

- 8.2 Procedure:

- 1. Remove and safeguard the magazine.

- 2. Draw back slide 4 to the stop and arrest it in the open position.

- 3. Verify (visually or with a tool) that there is no bullet, round, case or foreign body in the chamber or barrel bore (see Fig....

- 4. Remove round, cartridge case or foreign bodies. Clean, lubricate and assemble the pistol (see Section 7.3 and 7.4).

- 5. Have the pistol inspected by an armourer or gunsmith.

- 8.3 Safekeeping and storage of the pistol

- 8.4 Shipping the pistol

- 1. Check the pistol to ensure that it is unloaded and decocked.

- 2. Pack the pistol well (if possible in its original packaging) to prevent damage in transit. To prevent the pistol being recogn...

- 3. Enclose a letter stating the following:

- 4. Send the pistol properly insured and carriage- paid (packages without correct postage will not be accepted) to:

- 9 Product line

- 10 Disposal

- 8.4 Shipping the pistol

- 7.1 Stripping the pistol

- 11 Technical data/types/accessories

- 12 Spare parts

Maintenance

19 07.01GB

8. Flip up the takedown lever 16 clockwise.

.

9. Press decocking lever 40 down (Not applicable

to DAO pistols).

Note:

• The pistol is unloaded and decocked.

7.5 Verification of functions

Note:

• Verification of functions must be conducted on

the assembled pistol:

– to identify causes of malfunction,

– after completion of repairs,

– and after each cleaning and assembly of

the pistol.

Procedure:

1. Make sure that the magazine is removed and

the pistol unloaded (see Section 5.8).

2. Check the elasticity of the recoil spring 3 and

the smoothness of the slide 4 (no jamming).

– Draw back slide to the stop and allow it to fly

forward.

– Check that slide is impelled forward with

sufficient energy and that it engages.

– Repeat the verification test.

3. Check the double-action trigger (DA).

– With hammer 29 decocked, pull trigger 20

through.

– Check that hammer cocks and that at the

end of trigger travel, it strikes firmly forward

and comes to rest ini the safety intercept

notch.

4. Check trigger travel and trigger interruption.

– With hammer 29 decocked and trigger 20

pulled through, draw back slide 4 to the stop

and release it.

– Check that hammer 29 is restrained in its

cocked position (trigger remains pulled

through).

(Not applicable to DAO pistols. With DAO

pistols, decocked hammer 29C must be

registered in the safety intercept notch).

5. Check simple trigger function (SA).

(Not applicable to DAO pistols)

– Release trigger 20.

– Check that trigger bar 22 reengages and

whether hammer 29 drops when the trigger

is pulled again.

6. Check function of decocking lever 40 and

safety intercept notch on hammer 29.

– Cock hammer 29 and decock it with

decocking lever 40 without touching trigger

20 (not applicable to DAO pistols).

– Check that hammer 29 is arrested in the

safety intercept notch before reaching its

forward end position and trigger is guided to

the rest position.

7. Check slide catch lever 18.

– Insert empty magazine, draw back slide 4 to

the stop and release it.

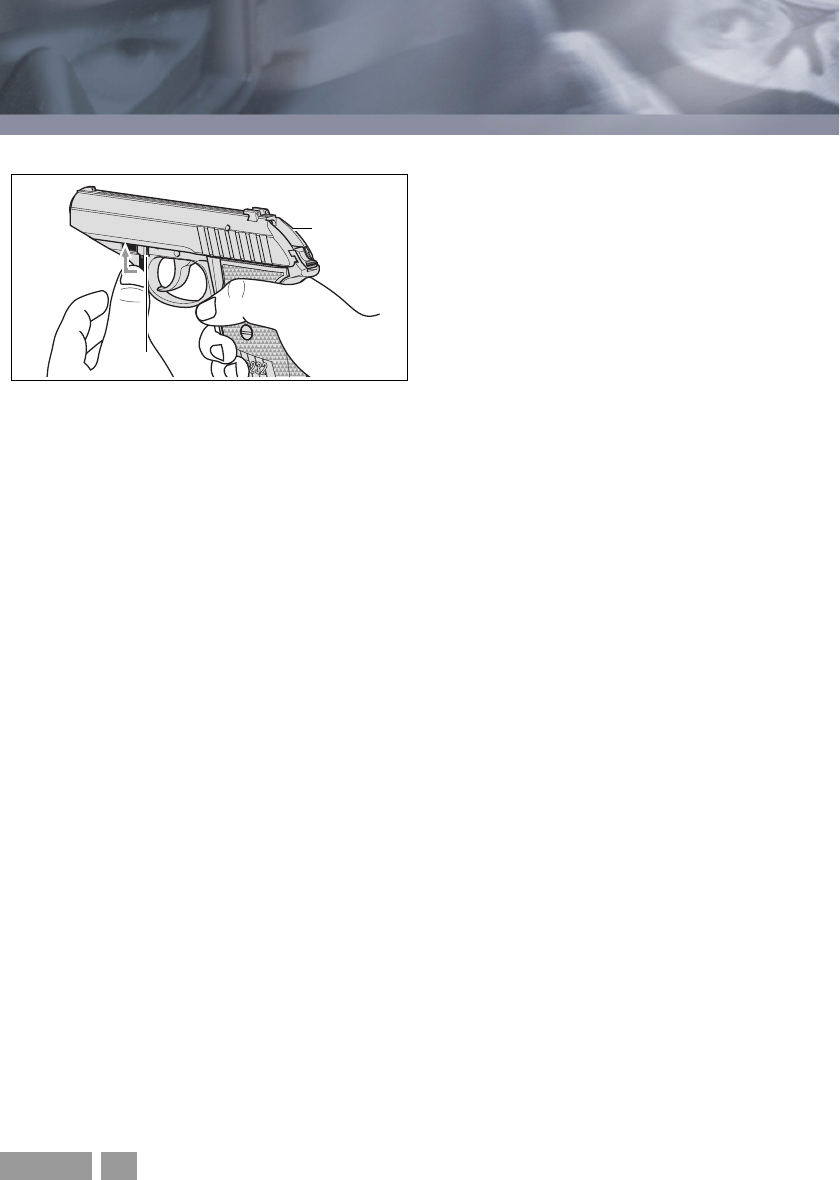

Fig. 17

16

4