User's Manual

Table Of Contents

- SITRANS LR250 (FOUNDATION FIELDBUS)

- Legal information

- Table of contents

- 1 Introduction

- 2 Safety notes

- 3 Description

- 4 Installing/mounting

- 5 Connecting

- 6 Commissioning

- 7 Remote operation

- 7.1 Operating via AMS Device Manager

- 7.1.1 Functions in AMS Device Manager

- 7.1.2 Key features of AMS Device Manager Rev. 9.0

- 7.1.3 Adding a new device

- 7.1.4 Master Reset

- 7.1.5 Scan Device

- 7.1.6 Sensor calibration

- 7.1.7 Configuring a new device

- 7.1.8 Changing parameter settings using AMS Device Manager

- 7.1.9 Configure/Setup (Level Transducer Block-LTB)

- 7.1.10 Configure/Setup (Liquid Crystal Display Block-LCD)

- 7.1.11 Configure/Setup (Diagnostic Transducer Block-DIAG)

- 7.1.12 Configure/Setup (Resource Block - RESOURCE)

- 7.1.13 Device Diagnostics (Level Transducer Block - LTB)

- 7.1.14 Device Diagnostics (Liquid Crystal Display Block - LCD)

- 7.1.15 Device Diagnostics (Diagnostic Transducer Block - DIAG)

- 7.1.16 Device Diagnostics (Resource Block - RESOURCE)

- 7.1.17 Process Variables (Level Transducer Block - LTB)

- 7.1.18 Password Protection

- 7.1.19 AMS menu structure

- 7.1 Operating via AMS Device Manager

- 8 Parameter reference

- 9 Service and maintenance

- 10 Diagnosing and troubleshooting

- 11 Technical data

- 12 Dimension drawings

- 12.1 Threaded horn antenna

- 12.2 Threaded horn antenna with extension

- 12.3 Flanged horn antenna

- 12.4 Flanged horn antenna with extension

- 12.5 Flanged encapsulated antenna (2"/DN50/50A sizes only)

- 12.6 Flanged encapsulated antenna (3"/DN80/80A sizes and larger)

- 12.7 Threaded PVDF antenna

- 12.8 Threaded connection markings

- 12.9 Raised-Face flange per EN 1092-1 for flanged horn antenna

- 12.10 Raised-Face flange per EN 1092-1 for flanged encapsulated antenna

- 12.11 Flat-Face flange

- 12.12 Process connection tag (pressure rated versions)

- A Appendix A: Technical reference

- B Appendix B: Communications via Foundation Fieldbus

- C Appendix C: Certificates and support

- 13 List of abbreviations

- 14 LCD menu structure

- Glossary

- Index

Commissioning

6.2 Application examples

SITRANS LR250 (FOUNDATION FIELDBUS)

58 Operating Instructions, 01/2014, A5E32221411-AB

6.2.2

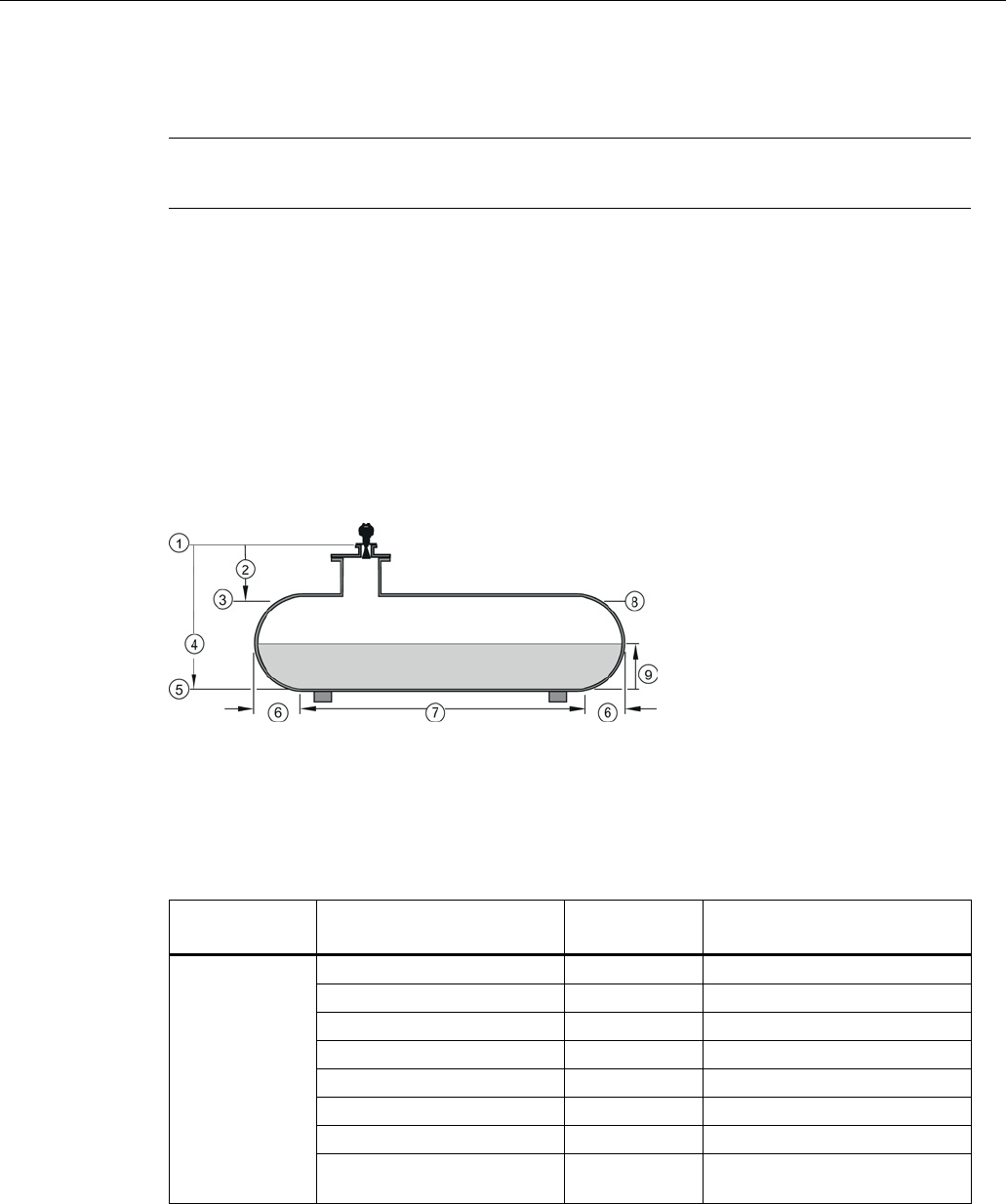

Horizontal vessel with volume measurement

Note

The minimum distance from the flange face to the target is lim

ited by

Near Range (2.5.1.)

.

To obtain level measurement proportional to vessel volume in a chemical vessel:

● Low Calibration Point = 3.5 m (11.48 ft) from sensor reference point

● High Calibration Point = 0.5 m (1.64 ft) from sensor reference point

● Max. fill/empty rate = 0.2 m/min (0.65 ft/min)

● Select vessel shape, Parabolic Ends, and enter values for A and L, to obtain a volume

reading instead of level.

In the event of a loss of echo:

● SITRANS LR250 is to report a status of BAD or UNCERTAIN after 120 seconds (2 minutes).

①

Sensor reference point

⑥

A = 0.8 m

②

0.5 m

⑦

L = 6 m

③

High calibration point

⑧

100% = 8000 L

④

3.5. m

⑨

Volume reading

⑤

Low calibration point

Parameter type

Parameter Name

Options/

Values

Function

Quick Start

Wizard

parameters

Introduction

NEXT

Continue with Wizard.

Language

NEXT

Continue with current language.

Material

LIQUID

Response Rate

MED

Medium =1 m/minute

Units

M

meters

Low Calibration Point

3.5

3.5 m (11.48 ft)

High Calibration Point

0.5

0.5 m (1.64 ft)

Wizard Complete

FINISH

Transfers Quick Start settings to

device.