Technical information

IM-P343-29 CH Issue 5 7

3. Technical information

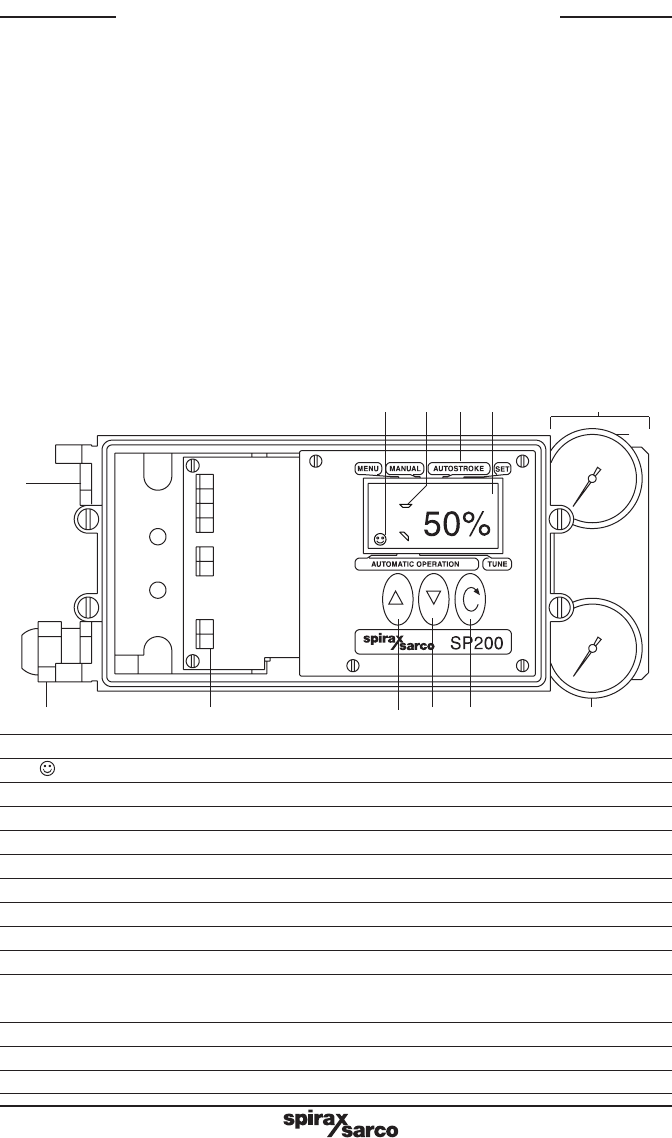

No. Part

1. indicating all OK. (! indicates an error)

2. Main menu functions with LCD flag indication

3. Signal pressure to actuator

4. Gland connection for wiring Pg 13.5

5. Terminal block

6. Increase value or toggle value key

7. Decrease value or toggle value key

8. Enter key

9. Supply pressure to positioner

10. Optional pressure gauge block with gauges -

2 gauges for single action, 3 gauges for double action version

11. Display of programming data, mA input signal and % travel

12. Spare Pg 13.5 gland connection for wiring 4-20 mA retransmission or software switches

13. Status of software configured travel switches.

4 5 6 7 8 9

3.1 Description

The SP200 smart valve positioner is loop powered from a 4 - 20 mA input signal to provide

accurate adaptive positional control of pneumatic actuated linear and quarter turn valves.

Precise control is maintained through valve position feedback that automatically varies the

pneumatic output pressure to overcome the effects of stem friction and flow forces to maintain

desired valve position. Indication of valve position is provided through a continuous digital

display of % travel. Valve position feedback is retrieved by means of a non contact technology

based on Hall effect. Therefore, high resolution, high reliability and vibration insensitivity are

guaranteed.

The SP200 includes many smart functions that can be fully programmed through menu driven

software using an integral keypad and LCD alphanumeric data. Valve commissioning is

simplified through an autostroke routine and display of programming status, software travel

switch status, mA input signal and valve diagnostics data. Moreover, the absence of mechanical

linkages between valve stem and positioner, drastically simplifies the mounting procedure and

reduces the time required. The SP200 is supplied with a NAMUR standard mounting kit for

attachment to yoke or pillar mounted actuators. For quarter turn valves, a mounting kit

compliant to VDI / VDE 3845 is supplied.

Fig. 1

12

1 13 2 11 10

3