Product Manual

STEP 1 - PRE-ASSEMBLY (CONTINUED)

1.3 Anchor bolts and concrete floor guidelines:

• Use 3/4”, grade 5 anchor bolts (included).

• Anchor bolts must be embedded at least 4”

into floor, not to exceed 3/4 of floor depth

(diagram 1A).

Note: A minimum 6”-thick reinforced concrete

floor is required. If other style anchor or

floor conditions exist consult anchor

manufacturer for requirements.

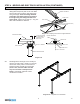

STEP 2 - COLUMN WELDMENT INSTALLATION

2.1 Lay out and mark on floor exact position of column weldments

prior to proceeding with installation (refer to enclosed General

Arrangement Drawing for recommended dimensions and

column weldment location).

2.2 Position first column weldment in place. Orient column cap

plate (top of column) as shown in diagram 2A.

2.3 While supporting column weldment, drill holes in concrete floor

using pre-drilled holes in column weldment base angles as a

guide (use 3/4” drill bit). Vacuum or brush away cement dust.

2.4 Install anchor bolts and hardware according to diagram 1A.

Do not fully torque nuts at this point.

2.5 Check to see if column weldment is plumb. If column weldment

is not plumb, place steel shims (not included) or grout (not

included) under base of column weldment until plumb. After

column weldment is plumb, tighten all nuts to recommended

torque of 70 ft/lb.

2.6 Install remaining column weldments (repeat Steps 2.2

through 2.5). Add grout under base.

4

1/11

Diagram 1A. Anchor bolt embedment.

Max. anchor bolt load = 84 lbs.

IMPORTANT: Be sure that column cap plate (top of column) is oriented in the proper direction as shown in

diagram 2A.

Diagram 2A. Orienting column cap plate.

BASE ANGLE

1/2”

COLUMN CAP

PLATE

RUNWAY

COLUMN WELDMENT

Diagram 2B.

3/4” Ø ANCHOR BOLT

HEX NUT

LOCKWASHER

FLATWASHER

4” MIN.

(EMBEDMENT)

6”