Product Manual

INSPECTION AND MAINTENANCE SCHEDULE

*Federal, state and local codes may require inspection and maintenance checks more often. Please check

the federal, state and local code manuals in your area.

WARNING

Any changes in rolling effort or unusual noises must be immediately identified and corrected. It is not necessary to

lubricate the track or bearings. Lubricating may attract airborne particles and may increase the rolling resistance.

(Do not use such substances as WD-40®, silicone sprays, oil or grease on bearings or on track flanges.)

600 Fishers Run, P.O. Box 593

Fishers, NY 14453-0593

Toll Free Phone: (855) 99-CRANE

E-Mail: info@shopcrane.com

http://www.shopcrane.com

© 2011 Shop Crane

All Rights Reserved

14

1/11

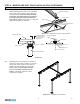

GORBEL® SHOP CRANE: INSPECTION AND MAINTENANCE SCHEDULE

ITEM COMPONENT MAINTENANCE FREQUENCY*

1 Runway/Column Hardware Check for full compression of lockwasher. Every 1,000 hours

2

Hoist Trolley / Wire Rope

Trolley

Check clevis pin. Check cotter pin. (Cotter pin should be fully wrapped

around clevis pin.) Check clevis bolt and hardware.

Every 1,000 hours

3

End Stops (both

runway and bridge)

Check for full compression of lockwasher. Every 1,000 hours

4 Wheels

Check for cracks and/or grooves: all of these increase pull forces. If any of

these conditions exist, wheels should be replaced.

Every 1,000 hours

5 End Trucks

Check for proper clamping hardware attachment. Ensure correct

position on bridge to match specified cantilevers. Inspect end truck

wheels following instructions for wheels above. Make sure body is free

of any bent materials, cracked or broken welds. Check for full

compression of lockwasher on clamping hardare.

Every 1,000 hours

6, 7

Runway and Bridge

Weldments

Clean interior of rail of dust or dirt particulate. If environment has

excessive dust or airborn particulates inspection may be required more

frequently.

Every 1,000 hours

4

3

2

3

1

5

6

7