Sherline Lathe User Guide and Specifications

FIGURE 21—The Sherline knurling tool holder.

Knurling Tool (P/N 3004)

Sherline's knurling system is designed to be used only with the Sherline Lathe. The

knurling holder mounts directly to the crosslide. A good knurl is produced by embossing,

not by cutting, and this creates high tool loads. Using two knurls opposing each other

equalizes these loads allowing successful knurling on a small machine. A number of

patterns can be achieved by changing the knurls. A 25 thread per inch medium diamond

pattern set comes with the tool. A number of additional straight and spiral knurls can be

ordered.

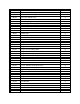

Guide to Approximate Turning Speeds

MATERIAL

CUT SPEED,

S.F.M.

1/4" (6mm) Dia.

1//2" (13mm) Dia.

1" (25mm) Dia.

Stainless, 303 67 1000 RPM 500 RPM 250 RPM

Stainless, 304 50 800 RPM 400 RPM 200 RPM

Stainless, 316 47 700 RPM 350 RPM 175 RPM

Steel, 12L14 174 2600 RPM 2300 RPM 650 RPM

Steel, 1018 87 1300 RPM 650 RPM 300 RPM

Steel, 4130 82 1250 RPM 650 RPM 300 RPM

Grey Cast Iron 57 900 RPM 450 RPM 225 RPM

Aluminum,

7075

400 2800 RPM 2800 RPM 1400 RPM

Aluminum,

6061

375 2800 RPM 2800 RPM 1400 RPM

Aluminum,

2024

268 2800 RPM 2000 RPM 1000 RPM

Brass 400 2800 RPM 2800 RPM 1400 RPM

FIGURE 22—Turning speeds for high speed steel cutting tools

TURNING SPEEDS

The chart above provides a guide to approximate speeds at which work of differing

materials should be rotated. Note that the turning speed is inversely proportional to the

diameter of the work; that is, the larger the diameter, the slower the turning speed.

Material often differs in its hardness, so these figures may have to be varied. The harder

the material, the slower the turning speed should be.