Technical data

Rev.February 1996 Conti-Dryer Page 12

CD 25-600

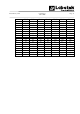

3.4 Capacity table

The values stated in the capacity table are directive only, as shape and bulk density of the

granule may infl uence the air speed and by that the drying ability. The tests are performed

using granule with a bulk density of 0.6 and a granular size of 2-3 mm.

Raw Material

PE Polyethylene 1.25 65-90 12 24 43 86 168 240 288

PP Polypropropylene 1.5 90 10 20 36 72 140 200 240

PS Polystyrene 1.5 80 10 20 36 72 140 200 240

SB Polystyrene

High impact 2.0 80 0.4 7.5 15 27 54 105 150 180

ABS Acrylonitrile

Butadiene Styrene 2.25 80 7 13.5 24 48 93 133 160

PPO Polyphenylene

Oxide 2.25 120 7 13.5 24 48 93 133 160

PVC Poly

Vinylchloride 2.25 65-70 0.5 7 13.5 24 48 93 133 160

SAN Styrene

Acrylonitrile 2.25 80 7 13.5 24 48 93 133 160

PI Polymide 2.25 120 6 12 21.5 43 84 120 144

CA Cellulose Acetate 2.75 75 1.0 5.5 11 19.5 39 76 109 131

PSU Polysulfene 2.75 120 5.5 11 19.5 39 76 109 131

CAB Cellulose-

Acetate Butrane 3.0 75 1.0 5 10 18 36 70 100 120

POM Polyacetal 3.0 100 5 10 18 36 70 100 120

AN Barex 3.25 80 4.5 9 16.5 33 65 92 111

PA Polyamide 6, 6/6

6.10 3.25 75-85 1.0 4.5 9 16.5 33 65 92 111

PUR Polyurethane 3.25 90 4.5 9 16.5 33 65 92 111

PMMA Polymethyl

Methacrylate 3.5 80 0.1 4 8.5 15.5 31 60 86 103

PE Polyethylene,

Black 3.75 75-85 1.0 4 8 14.5 29 56 80 96

CP Cellulose

Propionate 4.5 70-75 2.0 3.5 6.5 12 24 47 67 80

PA Polyamide 6/6, 6/6

6.10 4.5 70-75 2.0 3.5 6.5 12 24 47 67 80

- Inomere (Surlyn A) 5.5 65-70 3 5.5 10 20 38 55 65

Drying time in

hours

Recommended

drying temp.

Initial moisture

content

CL 25

CD 50

CD 90

CD 180

CD 350

CD 550

CD 600