How to Guide

Sales & Specifications Sheet • Issue Date December 2015

www.sharkbite.com · 2727 Paces Ferry Road · Building 2 · Suite 1800 · Atlanta · Georgia 30339 · USA

US Contact: 1-877-700-4242 · customerservice@sharkbite.com · Canadian Contact: 1-888-820-0120 · canadasales@rwc.com

A Division of Reliance Worldwide Corporation

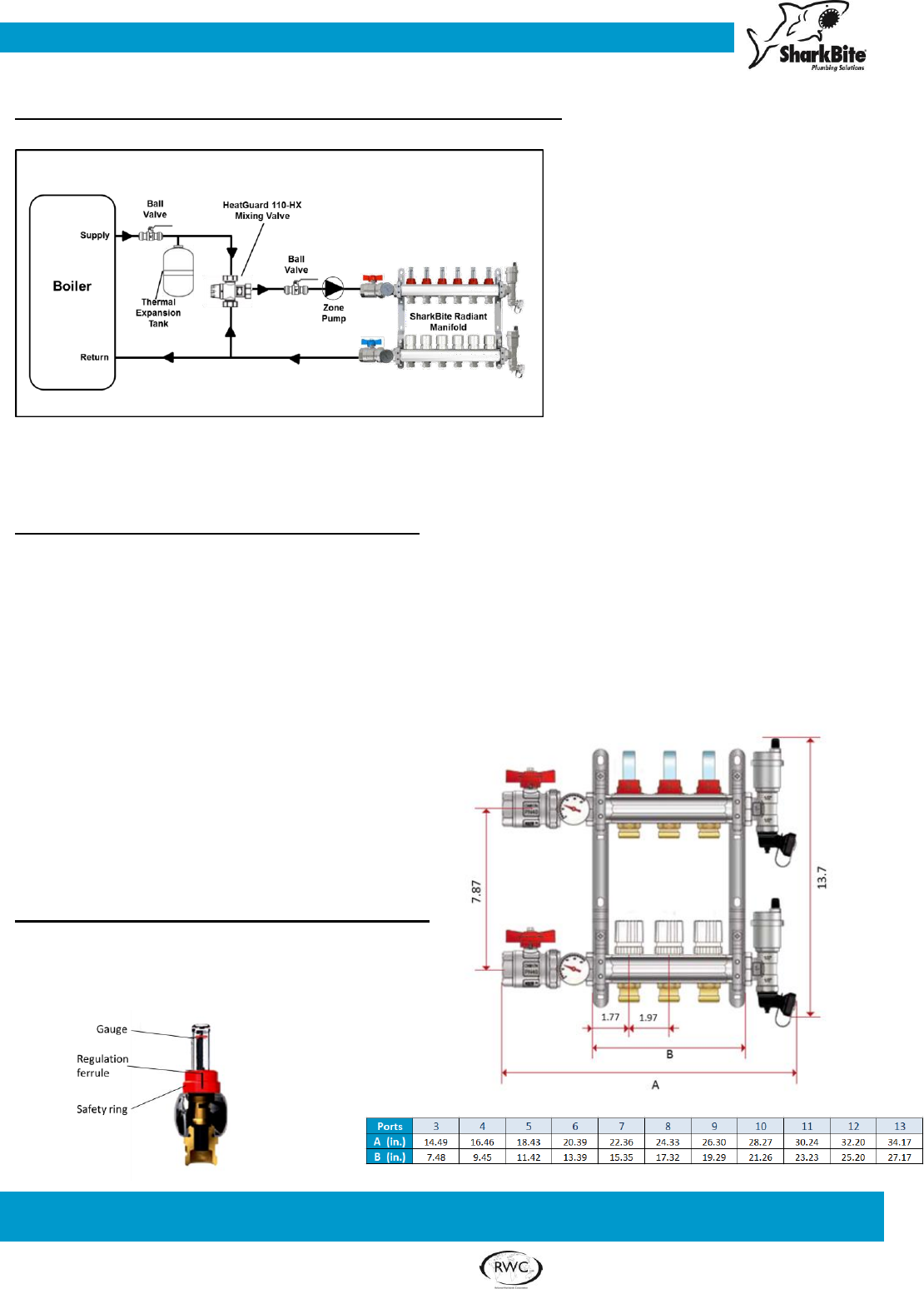

TYPICAL INSTALLATION

Closed-loop boiler application*.

*Please note that specific installation requirements will vary per system. Some components

may have been removed for simplicity.

SPECIFICATION DATA_________________

Performance:

Maximum operating temperature .................. 158°F (70°C)

Flow meter precision .................................... +/- 10%

Maximum operating pressure ....................... 87 psi (6 bar)

Flow rate, minimum ...................................... 0.34 gpm (1.3 l/min)

Flow rate, maximum ..................................... 11 gpm (42 l/min)

Maximum Area (room size)* ......................... approx. 665 ft

2

Materials:

Flow and return manifolds ............................ 304L Stainless Steel

Ball Valves .................................................... Nickel-Plated Brass

Air Vent and Drain ......................................... Nickel-Plated Brass

Brackets ........................................................ Zinc-plated steel

Seals ............................................................ EPDM

Piston ........................................................... Engineered Polymer

Guide tube .................................................... Noryl GFN2

*Max. Area estimated at total load 35 BTUh/ft2, setpoint 70°F (21°C), max. surface 87.5°F (30.8°C),

supply/return differential 10°F (5.6°C), 30% glycol, loops: 6, total length 200’ (61m) max. each

(active length 165’ (50.3m) each), installed 8" (20.3cm) on-center. Actual conditions will vary based

on room size.

CONNECTIONS________________________

Inlet FNPT ..................................................... 1”

SharkBite® Outlet .......................................... ½”

Flow Meter