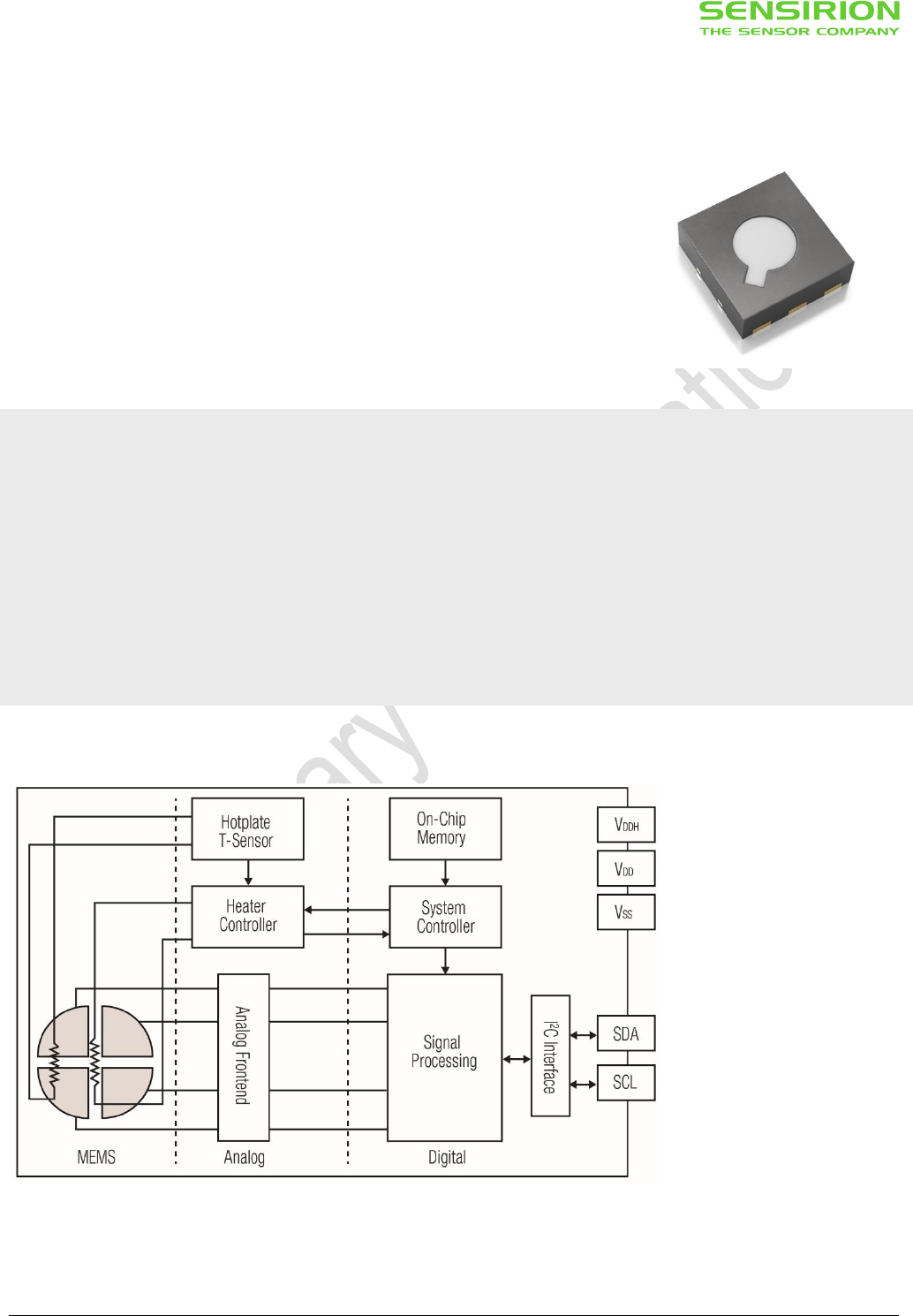

Datasheet SGP30 Sensirion Gas Platform Multi-pixel gas sensor for indoor air quality applications Outstanding long-term stability I2C interface with TVOC and CO2eq output signals Very small 6-pin DFN package: 2.45 x 2.45 x 0.9 mm3 Low power consumption: 48 mA at 1.8V Tape and reel packaged, reflow solderable Product Summary The SGP30 is a digital multi-pixel gas sensor designed for easy integration into air purifier, demand-controlled ventilation, and IoT applications.

1 Sensor Performance 1.1 Gas Sensing Performance Parameter Signal Values Measurement range1 Ethanol signal 0 ppm to 1000 ppm H2 signal 0 ppm to 1000 ppm Specified measurement range Ethanol signal 0.3 ppm to 30 ppm H2 signal 0.5 ppm to 10 ppm Ethanol signal see Figure 2 typ.: 15% of meas. value Accuracy3 Long-term drift3,4 Resolution Sampling frequency H2 signal see Figure 3 typ.: 10% of meas. value Ethanol signal see Figure 4 typ.: 1.3% of meas. value H2 signal see Figure 5 typ.: 1.

Long-term drift Ethanol signal Long-term drift H2 signal Figure 4 Typical and maximum long-term drift in % of measured value at 25°C, 50% RH and typical VDD. The sensors have been operated for at least 24h before the first characterization. Figure 5 Typical and maximum long-term drift in % of measured value at 25°C, 50% RH and typical VDD. The sensors have been operated for at least 60h before the first characterization. 1.

recommended range, especially at high humidity, may affect the sensor performance. Prolonged exposure to extreme conditions may accelerate aging. To ensure stable operation of the gas sensor, the conditions described in the document SGP Handling and Assembly Instructions regarding exposure to exceptionally high concentrations of some organic or inorganic compounds have to be met, particularly during operation. Please also refer to the Design-in Guide for optimal integration of the SGP30.

Figure 7 Typical application circuit (for better clarity in the image, the positioning of the pins does not reflect the positions on the real sensor). The electrical specifications of the SGP30 are shown in Table 3. The power supply pins must be decoupled with a 100 nF capacitor that shall be placed as close as possible to pin VDD – see Figure 7. The required decoupling depends on the power supply network connected to the sensor. We also recommend VDD and VDDH pins to be shorted7.

5 Timing Specifications 5.1 Sensor System Timings The timings refer to the power up and reset of the ASIC part and do not reflect the usefulness of the readings. Parameter Symbol Condition Min. Typ. Max. Unit Comments Power-up time tPU After hard reset, VDD ≥VPOR - 0.4 0.6 ms - Soft reset time tSR After soft reset - 0.4 0.6 ms - Table 6 System timing specifications. 5.2 Communication Timings Parameter Symbol Conditions Min. Typ. Max.

6 Operation and Communication The SGP30 supports I2C fast mode. For detailed information on the I2C protocol, refer to NXP I2C-bus specification8. All SGP30 commands and data are mapped to a 16-bit address space. Additionally, data and commands are protected with a CRC checksum to increase the communication reliability. The 16-bit commands that are sent to the sensor already include a 3-bit CRC checksum. Data sent from and received by the sensor is always succeeded by an 8-bit CRC.

Air Quality Signals The SGP30 uses a dynamic baseline compensation algorithm and on-chip calibration parameters to provide two complementary air quality signals. Based on the sensor signals a total VOC signal (TVOC) and a CO2 equivalent signal (CO2eq) are calculated. Sending an “Init_air_quality” command starts the air quality measurement.

Measure Test The command “Measure_test” which is included for integration and production line testing runs an on-chip self-test. In case of a successful self-test the sensor returns the fixed data pattern 0xD400 (with correct CRC). Feature Set 0x0020 Command Hex. Code Parameter length including CRC [bytes] Response length including CRC [bytes] Measurement duration [ms] Typ. Max.

Hex. Code Address byte 0x00 Second byte 0x06 Reset Command using the General Call address 0x0006 2 3 4 5 6 7 8 9 1 ACK 1 S General Call Address 2 3 4 5 6 7 Reset Command 8 9 ACK Command General Call 2nd byte st General Call 1 byte Table 11 Reset through the General Call address (Clear blocks are controlled by the microcontroller, grey blocks by the sensor.). 6.

6.7 Communication Data Sequences Figure 9 Communication sequence for starting a measurement and reading measurement results. 7 Quality 7.1 Environmental Stability The qualification of the SGP30 will be performed based on the JEDEC JESD47 qualification test method. 7.2 Material Contents The device is fully RoHS and WEEE compliant, e.g., free of Pb, Cd, and Hg. 8 Device Package SGP30 sensors are provided in a DFN (dual flat no leads) package with an outline of 2.45 × 2.45 × 0.

8.3 Package Outline 2.45 0.3x45o 0.9 0.35 1.7 2.45 0.8 0.2* 0.4 1.25 Figure 11 Package outlines drawing of the SGP30 with nominal values. Dimensions are given in millimeters. The die pad shows a small recess in the bottom left part. * These dimensions are not well defined and given as a reference only. 8.4 Landing Pattern Figure 12 shows the PCB landing pattern. The landing pattern is understood to be the metal layer on the PCB, onto which the DFN pads are soldered.

9 Tape & Reel Package Ø1.5 +.1 /-0.0 4.00 2.00 ±.05 SEE Note 2 0.30 ±.05 Ø1.00 MIN 1.75 ±.1 4.00 SEE Note 1 A 5.50 ±.05 SEE NOTE 2 R 0.2 MAX. B0 B 12.0 +0.3/-0.1 A R 0.25 TYP. K0 A0 A0 = 2.75 B0 = 2.75 K0 = 1.20 SECTION A - A TOLERANCES - UNLESS NOTED 1PL ±.2 2PL ±.10 NOTES: 1. 10 SPROCKET HOLE PITCH CUMULATIVE TOLERANCE ±0.2 2. POCKET POSITION RELATIVE TO SPROCKET HOLE MEASURED AS TRUE POSITION OF POCKET, NOT POCKET HOLE 3.

11 Important Notices 11.1 Warning, Personal Injury Do not use this product as safety or emergency stop devices or in any other application where failure of the product could result in personal injury. Do not use this product for applications other than its intended and authorized use. Before installing, handling, using or servicing this product, please consult the data sheet and application notes. Failure to comply with these instructions could result in death or serious injury.

12 Headquarters and Subsidiaries Sensirion AG Laubisruetistr. 50 CH-8712 Staefa ZH Switzerland Sensirion Inc., USA phone: +1 312 690 5858 info-us@sensirion.com www.sensirion.com Sensirion Korea Co. Ltd. phone: +82 31 337 7700~3 info-kr@sensirion.com www.sensirion.co.kr phone: +41 44 306 40 00 fax: +41 44 306 40 30 info@sensirion.com www.sensirion.com Sensirion Japan Co. Ltd. phone: +81 3 3444 4940 info-jp@sensirion.com www.sensirion.co.jp Sensirion China Co. Ltd.