User Manual

6

C. Inspect keyways and oil holes for burrs in ywheels and remove if necessary.

D. With key in shaft, insert into respective tapered hole in ywheel and check to see that key does not bottom in groove. If key bottoms out,

le at side of key, not rounded side, until shaft with key in place ts in ywheel without bottoming out. Check crankpin and crankpin key

also.

E. Using lacquer thinner, clean mainshaft tapers, crankpin and ywheel tapers again.

F. Assemble mainshafts in respective ywheels. Coat taper and threads of each shaft with green Loctite® during assembly. Install crankpin

in camside ywheel using Loctite also. Tighten all nuts to at least factory torque specs minimum. When S&S shafts are used, follow

instructions included with them.

NOTE:

After right side ywheel, pinion shaft and crankpin are assembled, blow air through pinion shaft oil feed hole to check for blockage.

Partially or completely blocked oil feed passageways may cause irreversible damage to bearings and other engine components.

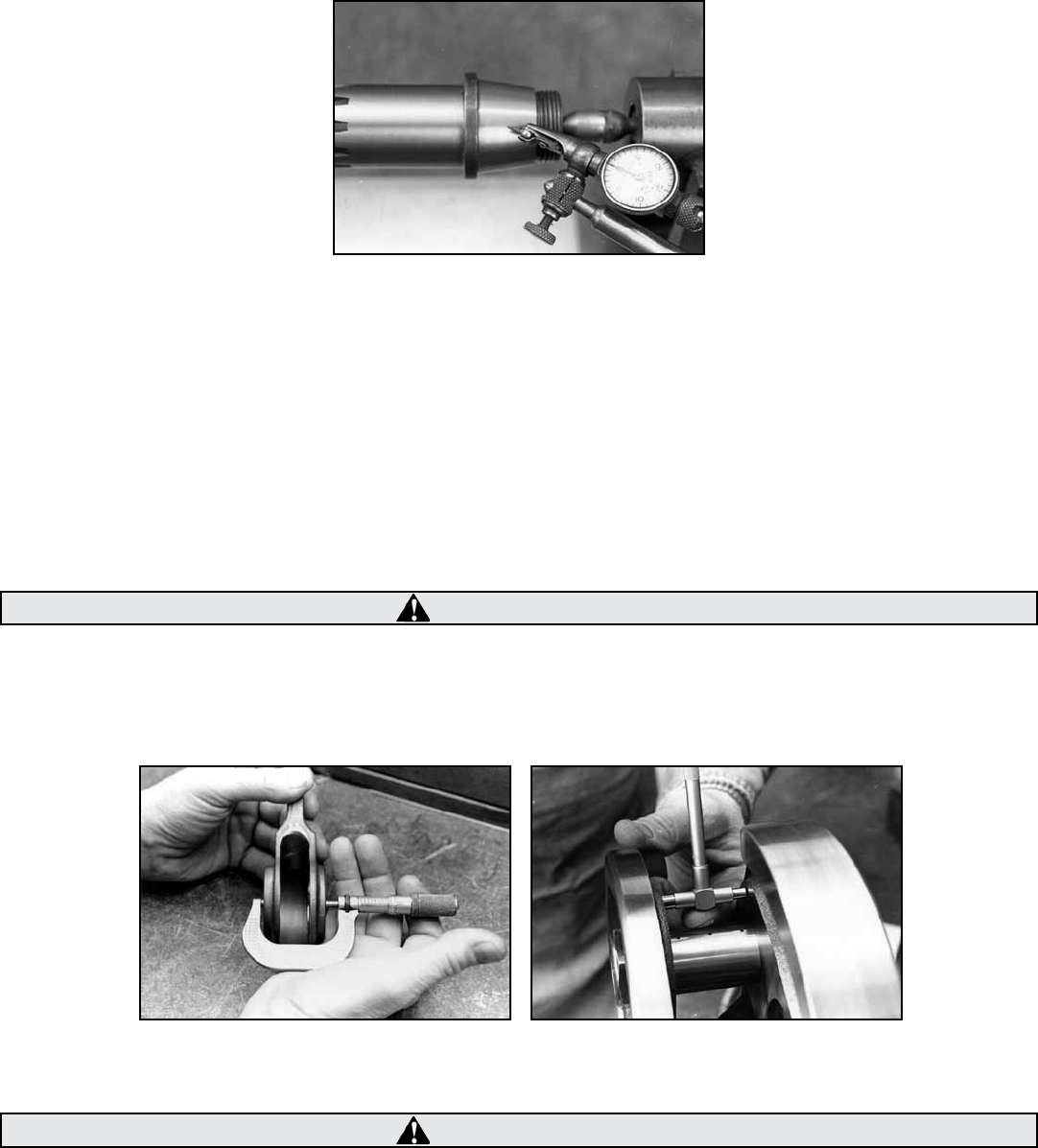

G. Measure width of female rod on crankpin end. See Picture 3, below left. Measurement should be 1.743" to 1.745".

H. Assemble left and right ywheels and moderately snug nuts. Do not worry about them being true. Measure distance between connecting

rod thrust pads. See Picture 4, below right.

NOTE: S&S recommended rod side play is .015" to .035". Rod Side Play = (Distance from Pad to Pad) - (Female Rod Width)

Incorrect connecting rod side play may cause excessive rod side thrusting and potential damage to rods, ywheels and other engine

components.

If dierence is less than .020", female rod must be ground on sides as nal tightening will pull wheels closer together. Rod side play diminishes

about .015" when crankpin nut is nal tightened. Take equal amounts o each side if amount to be removed is more than .010". If there is

no rod side play try dierent crankpin. If rod side play is more than .035", try dierent crankpin. We have run side play of as much as .045"

without serious consequences. If crankpin is changed check rod bearing clearance. If side play is excessive and dierent crankpins do not correct

problem, contact us.

Picture 2

CAUTION

Picture 3 Picture 4

CAUTION