User Manual

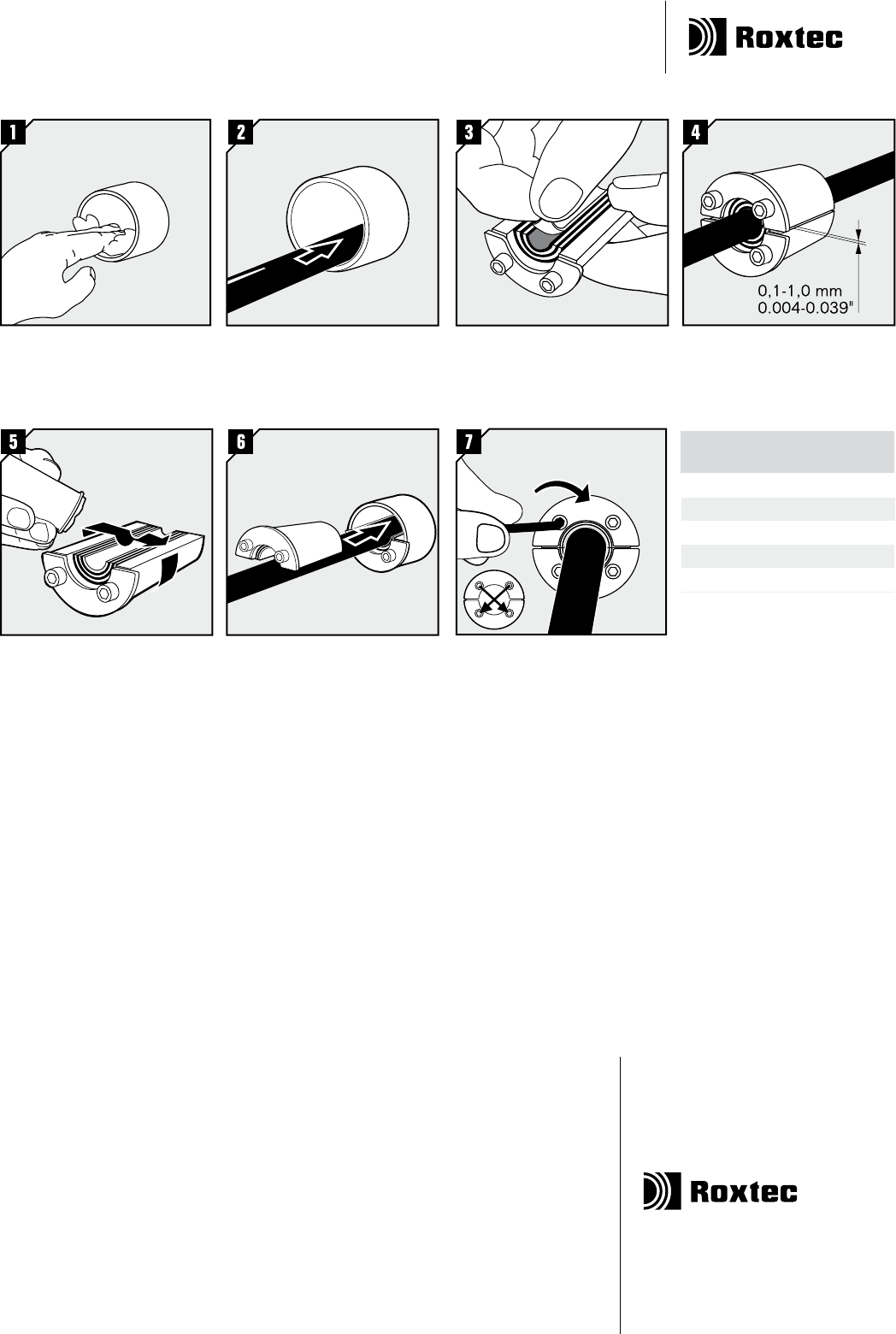

Adapt the seal to the cable/pipe by

peeling layers from the halves until

you reach the gap seen in pic.4.

Remove any dirt in the sleeve/

hole.

Pull the cable/pipe through Try to achieve a 0.1-1.0 mm gap

between the two halves when held

against the cable/pipe.

Disassembly instruction

Reverse order

Tighten the screws crosswise.

The seal will compress and seal

the transit. Please see table for

recommended max torque.

Lubricate thoroughly on the inside

surfaces and sparsely on the

outside of the seal with Roxtec

Lubricant.

Insert the halves, one by one, into

the sleeve.

RS seal installation

ASS2005002701 ver_1.3/GB/0906/annsve

* The recommended max torque

depends on several things e.g cable

or pipe size, amount of used lubricant,

sleeve size or material in the cable

sheet etc.

Size: Rec. Max Torque*

RS (Nm)

23 - 31 1

43 - 100 4

125 - 200 7

225 - 400 17

450 - 644 35

For optimum relability, wait 24 hours or longer after installation before exposing the cables/pipes to strain or pressure.

Cable/pipe shall be routed perpendicular to the sleeve or hole.

Cable/pipe with a considerable weight needs to be supported to prevent damages or subsidiences to the seal.

Note

Roxtec ® and Multidiameter ® are registered trademarks of Roxtec in Sweden and/or other countries.

Roxtec International AB

Box 540, 371 23 Karlskrona, SWEDEN

PHONE +46 455 36 67 00, FAX +46 455 820 12

EMAIL info@roxtec.com, www.roxtec.com

DISCLAIMER

”The Roxtec cable entry sealing system (”the Roxtec system”) is

a modular-based system of sealing products consisting of different

components. Each and every one of the components are necessary for

the best performance of the Roxtec system. The Roxtec system has

been certified to resist a number of different hazards. Any such certifi-

cation, and the ability of the Roxtec system to resist such hazards, is

dependent on all components that are installed as a part of the Roxtec

system. Thus, the certification is not valid and does not apply unless all

components installed as part of the Roxtec system are manufactured

by or under license from Roxtec (“authorized manufacturer”). Roxtec

gives no performance guarantee with respect to the Roxtec system,

unless (I) all components installed as part of the Roxtec system is

manufactured by an authorized manufacturer and (II) the purchaser is in

compliance with (a), and (b), below.

(a) During storage, the Roxtec system or part thereof, shall be

kept indoors in its original packaging at a temperature not exceeding

+70°C/+158°F and not below -40°C/-40°F.

(b) Installation shall be carried out in accordance with Roxtec

installation instructions in effect from time to time.

The product information provided by Roxtec does not release the

purchaser of the Roxtec system, or part thereof, from the obligation to

independently determine the suitability of the products for the intended

process, installation and/or use.

Roxtec gives no guarantee for the Roxtec system or any part thereof

and assumes no liability for any loss or damage whatsoever, whether

direct, indirect, consequential, loss of profit or otherwise, occurred or

caused by the Roxtec systems or installations containing components

not manufactured by an authorized manufacturer.

Roxtec expressly excludes any implied warranties of merchantability

and fitness for a particular purpose and all other express or implied

representations and warranties provided by statute or common law.

User determines suitability of the Roxtec system for intended use

and assumes all risk and liability in connection therewith. In no event

shall Roxtec be liable for consequential, punitive, special, exemplary or

incidental damages.”