User Guide

12

Calibration – Relative Humidity System (hygroscopic membrane)

Switch off the electrical supply to the recorder.

During manufacture the measuring element is calibrated in atmospheres of known equivalent relative humidity.

These atmospheres are generated by specific salt solutions at constant temperature in apparatus which is unlikely

to be available to the average instrument user.

Calibration checks can be made without salt solution by using a Whirling Hygrometer and comparing the pen

record with figures obtained from psychrometric tables (see page 7) in various ambient relative humidities, taking

care to allow the recorder time to stabilise at each reading.

Make sure all pivots and linkages are free moving and adjust as follows:

Allow the recorder to stabilise with the measuring element in a low ambient R.H. Pen should record within

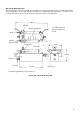

±2% R.H. of correct value. If not, adjust zero screw J Fig. 4, in the mounting of the humidity element.

Allow the recorder to stabilise with the measuring element in a high ambient R.H. Pen should record within

±2% R.H. of correct value. If not, adjust by moving the position of the link pivot on the cockpiece ratio arm,

Fig. 4. In order to move the link loosen the nut at the back of the pivot. Raising the pivot will increase the

pen movement and lowering the pivot will reduce the movement. Re-tighten after adjustment.

Repeat steps 1 and 2 until pen records within ±2% of true R.H. at both positions on chart.

Linearity Adjustments to the measuring systems

Linearity adjustments are only likely to be needed if a measuring element has been replaced. Switch off the

electrical supply to the recorder. Follow the appropriate calibration procedure making an additional calibration

check at approximately centre span after the instrument has been adjusted to record correctly at high and low

readings. If necessary, slightly adjust the length of the connecting link (see Figs. 4 and 5). To gain access to the

connecting link remove the chart, pens and upper chart plate as described under Access to Recorder. After

adjusting the length of the link replace the chart plate, etc. recalibrate at high and low readings and then repeat

the centre span calibration check. Continue to make adjustments in this order until the record at all three points is

within specification.

Servicing – General

Every six months lubricate metal bearings using a good quality molybdenised clock oil, such as Moebius 8040/35

clock oil. Do not use this lubricant on any nylon parts. Wipe off any excess lubricant with a clean lint free cloth.

Oiling the mechanical clock

After a long period of operation the clock should be oiled. The complete clock can be detached by unscrewing the

three fixing screws when the chart plate is removed. Use a high grade of clock oil. (This operation should only be

carried out by a suitably experienced person).

1.

2.

3.