User Guide

11

MAINTENANCE

Cutting a programme cam

The required programme should be drawn on to a spare recorder chart and transferred using carbon paper or a

similar method to the paper covering on the cam blank. Mark on this trace significant points of the programme

where the process state is important. Mark drilling centres on the radii of these programme points exactly 3mm

out from the points. Drill through with a 6mm drill. Join up the programme points using a saw, and smooth off the

profile between the points.

A cam cut in this way will only provide a programme which is an approximation to the requirement owing to

variations in the distance between the cam-follower and the pen at different positions on the chart. If required,

precise programme cams can be supplied to customers’ specifications.

Fitting a new pen arm

Refer to the SPARES LIST, page 15 for the part numbers of the two pen arms. Make sure the correct replacement

arm (front or rear pen) is obtained. Follow the fitting instructions outlined under Inking System, page 6.

After fitting a new arm check the pen indication on the chart near the zero end of the range. See Zero Adjustment,

page 7.

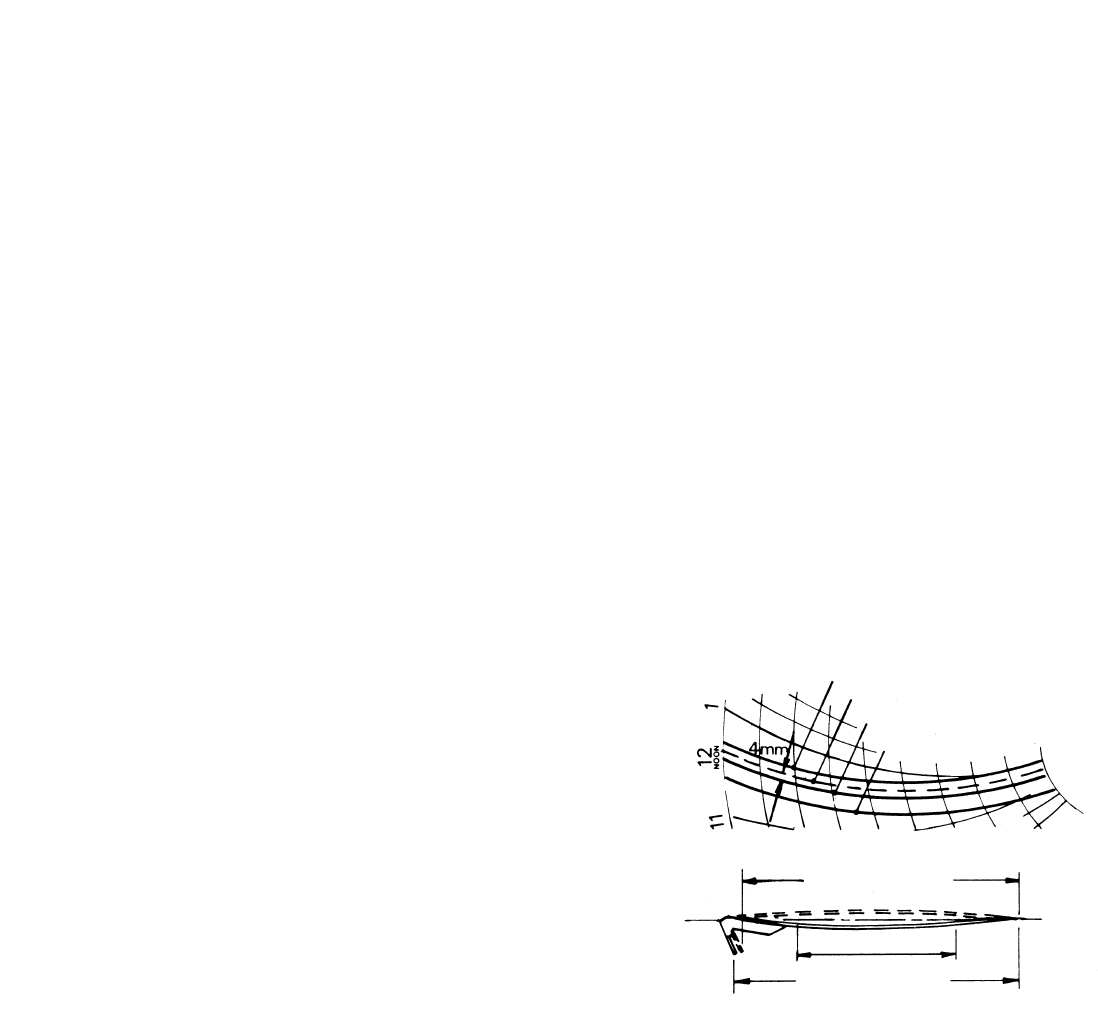

Pen Adjustment

The pen lifter must be below the arm before the clock is

started. If the pen is bent, the effective length of the pen

arm will be altered so that the pen will not record the

correct time at all temperatures. If when the chart is

stationary the time increases as the pen moves towards

the outside of the chart, the pen arm is too long, and

vice versa, see Fig. 9. The error can be corrected by

careful straightening of the pen or by bowing the pen

arm slightly. Adjust the pressure if necessary by bending

the hook Y in Fig. 3.

Instruments with more than one pen are adjusted in the

same way as those with only one. Each pen is adjusted

independently. The mounting for the pen arm closest to

the chart (the green pen) is reversed and the fibre tip nib

is shorter so that each pen can move freely across the

other’s path. Only the red pen will indicate the correct

time; the green pen being set to record 4mm in advance

of the red.

Calibration – Temperature or Pressure System; Wet and Dry Bulb Relative Humidity System

Switch off the electrical supply to the recorder.

Make sure all pivots and linkages are free moving and adjust as follows:

Allow recorder to stabilise with measuring element in a low temperature (or pressure) just above scale

minimum. Pen should record within ±1% of span of correct value. If necessary adjust zero screw S, Fig. 3.

If pen is significantly out of line with cockpiece, i.e. more than about 5 angular degrees, adjust screw S to

line up pen with cockpiece. Loosen the coarse zero adjustment screw holding the serrated compensator

carrier, Fig. 5. and adjust pen to record true value, making a fine adjustment on screw S after the coarse

zero adjustment screw has been re-tightened.

Allow the recorder to stabilise with measuring element in high temperature (or pressure) just under scale

maximum. Pen should record within ±1% of span of correct value. If not, adjust by moving the link

connecting the compensator arm to the ratio arm on the cockpiece, see Fig. 5. In order to move the link,

loosen the nut at the back of the ratio arm pivot. Raising the pivot will increase the pen movement and

lowering the pivot will reduce the movement. Re-tighten after adjustment.

Repeat steps 1 and 2 until no further adjustment is necessary.

1.

2.

3.

Fig. 9

Decrease length

Red pen arm too long

Red pen trace correct

Green pen trace correct

Red pen arm too short

Length of bow

Increase length