User Guide

Electrical alarm/control system

Each relay is switched by a contact mounted on an arm linked to the setting pointer which makes or breaks with a

contact attached to the recording pen linkage when the pen reaches the set point (see Fig. 5.). The striker is fixed

relative to the pen arm and a spring loaded contact is fitted to the setting pointer linkage. One set of changeover

contacts is available for external connection for each set point. The contacts are usually labelled “normally closed”

(NC), “common” (C) and “normally open”

(NO) where normally means that no current

is flowing through the relay coil. Refer to

page 14 for any special wiring information.

On wet and dry bulb humidity controllers in

addition to standard control contacts for the

dry temperature a contact may be fitted on

the dry bulb pen linkage so that the wet

bulb depression may be controlled.

Alarm systems should have an independent

power supply to safeguard alarm operation

in the event of mains failure.

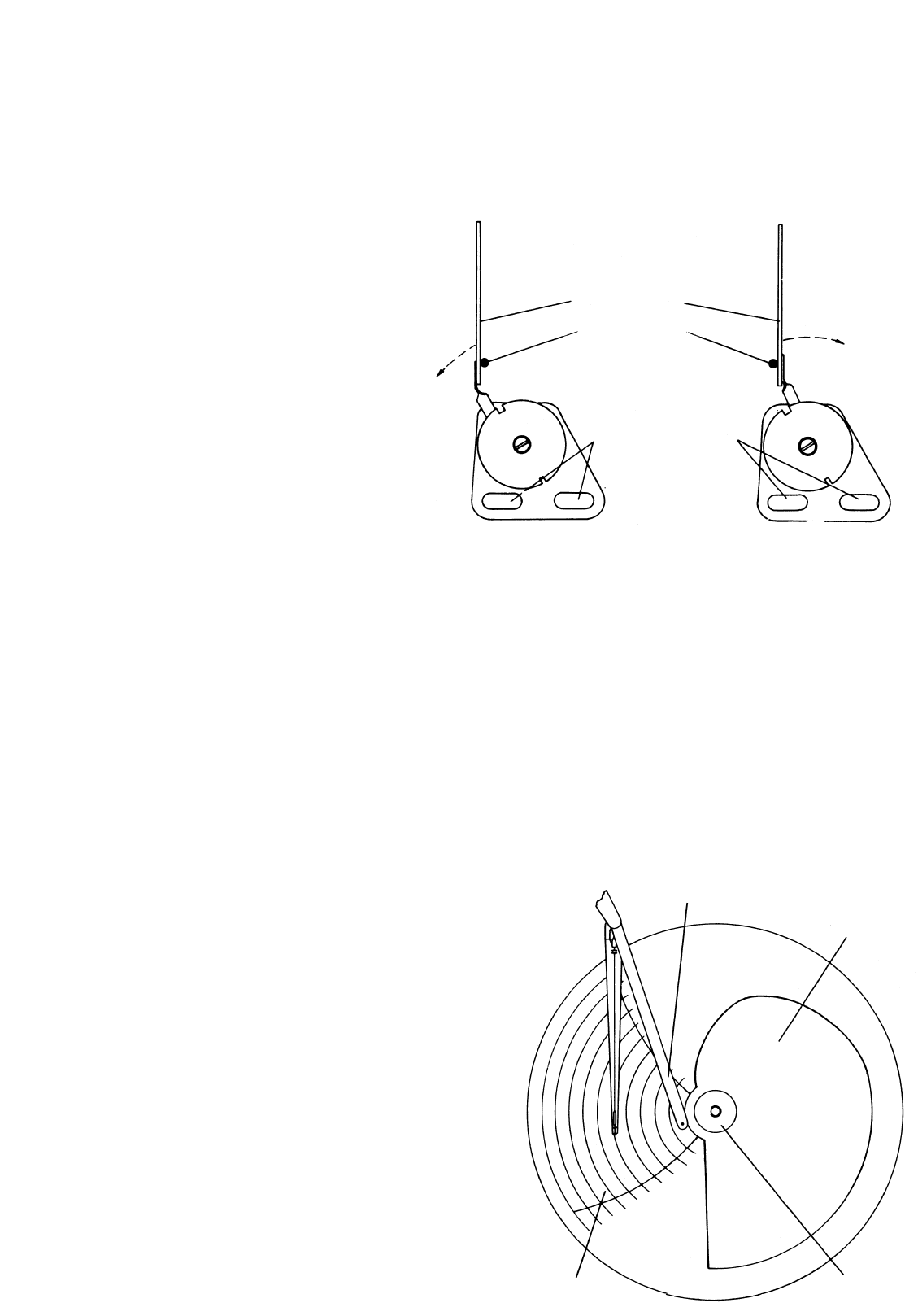

Adjusting the relay operating point

If the measured value indication is correct and the relay operates at a value other than that shown by the setting

pointer, the error may be corrected as follows. Move the setting pointer to the indicated value. Switch off the

electrical supply to the recorder and remove the chart, pens and upper chart plate. Slacken the two nylon screws

on the control unit (see Figs. 5 and 7) and slide it along the control arm until the sprung contact just touches the

fixed contact. Re-tighten the screws and replace the chart plate etc. Check the relay now operates at the desired

set point.

Changing the Control Action

Switch off the electrical supply to the recorder and remove the chart, pens and upper chart plate.

To change the relay action from energised below set point (E.B.) to energised above set point (E.A.) or vice-versa

the control unit incorporating the spring loaded contact should be unscrewed from the control arm and a unit with

the contact spring loaded in the reverse direction fitted in its place (see Fig. 7). Adjust the relay operating point as

described above. Tighten the screws and replace the chart plate etc.

Programme Control

Programming is provided by a shaped transparent cam

driven by the chart motor and linked by a cam follower

to a control unit inside the instrument case. The control

unit continually operates external regulating equipment

in accordance with the configuration of the cam. The

measuring system monitors and records the process

variable as in the basic C105 instrument.

The programming cam is mounted over the chart directly

on to the chart drive shaft. The cam follower is a pivoted

arm with a roller lightly sprung against the edge of the

cam at one end and a linkage to the internal control unit

at the other. The cam follower is deflected as the cam

rotates and actuates the electrical control unit. All cams

are interchangeable.

10

Fig. 7. Electrical Control Contacts

Fig. 8

Sprung contact

E.A.

E.B.

Striker pin

Slots for fixing screws

Part no. 15321–80

Cam follower

Programme cam

Cam clamp nut

Chart

Part no. 15321–79