Manual

6 © 2009, ROSS CONTROLS

®

.

All Rights Reserved.

Installation and Troubleshooting

INSTALLATION

• Locate the check valve as close to the cylinder as possible.

This will minimize cylinder bounce and drift.

• Use non-expandable hose between check valve and cylinder.

The expandability of thin-wall flexible hose can magnify cylinder

bounce and drift.

• To install threaded pipe or fittings, engage threads one turn,

apply thread sealant (tape not recommended) to threads, and

tighten pipe or fitting fully.

• After system is pressurized, check all connections with soapy

water to ensure that there are no leaks. Drifting can occur if

leaks are present between the check valve and the cylinder.

• Pressure at port P must be equal to or greater than the pressure

in the cylinder and greater than the minimum operating pressure

of the control valve.

• Do not restrict the exhaust of the control valve.

• In a circuit using a solenoid pilot check valve, the check valve

solenoid and a control valve solenoid must be energized

simultaneously.

TROUBLESHOOTING TIP

The most common cause of unsatisfactory performance is leaky

connections. Always check for leaks with before undertaking any

other repair procedures.

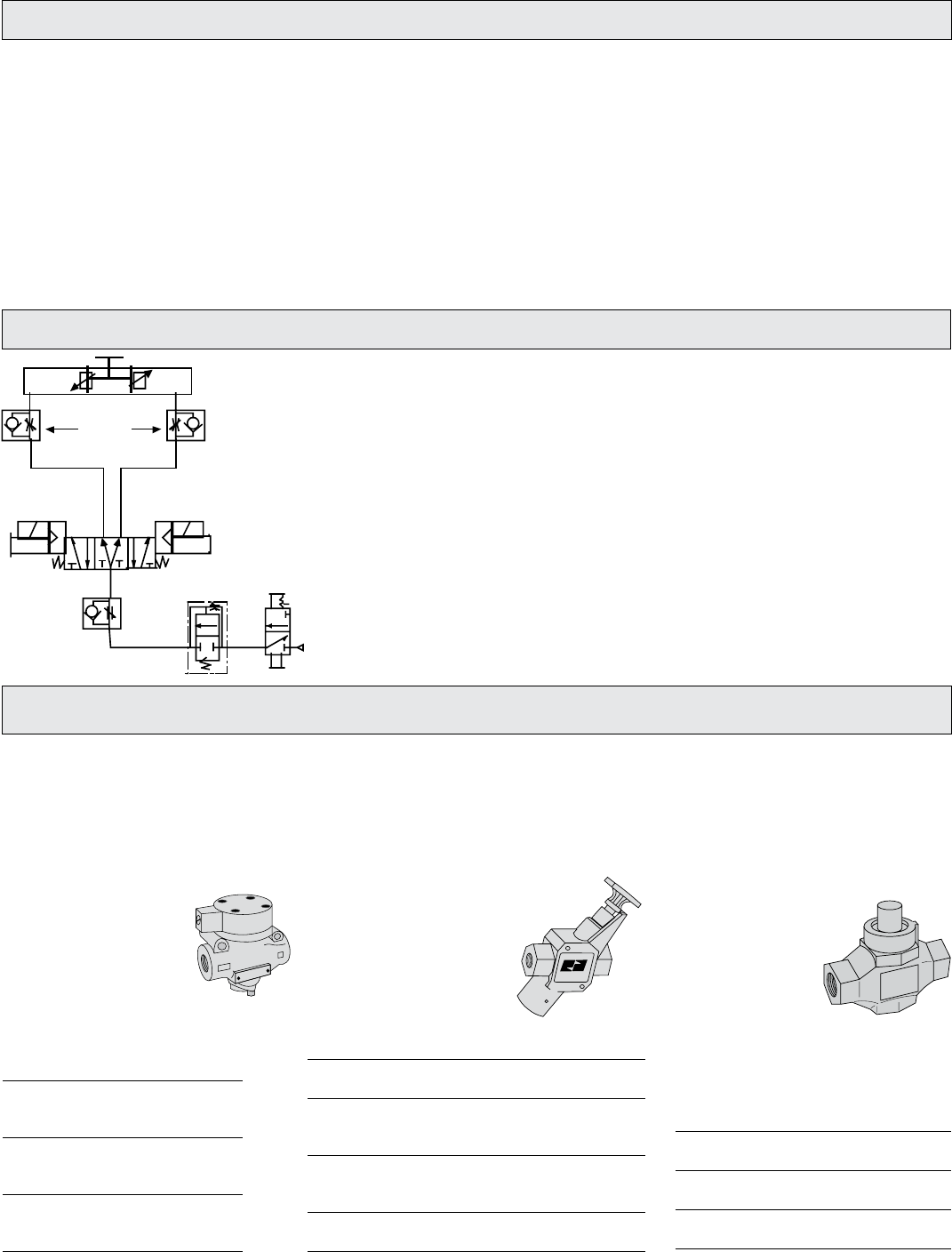

TYPICAL APPLICATIONS: Control of rodless cylinders, double-rod cylinders, air motors

on transfer systems, and part loaders.

CIRCUIT FEATURES:

• When the air supply is turned on, the EEZ-ON

®

valve (see below) slowly pressurizes

the cylinder to provide soft start recharging.

• Allows cylinder to be jogged in either direction.

• L-O-X

®

valve (see below) provides lockable shutoff of supply air, and exhausting of

trapped downstream air.

• Prevents runaways due to loss of air pressure.

Circuit for Control of Rodless Actuators

3-Position,

Pressure Center

Control V alve

Rodless

Cylinder

L-O-X

®

Valve

Flow

Control

Valves

Flow

Control

Valve

EEZ-ON

®

Valve

Other ROSS Valves Used in the Circuits

EEZ-ON

®

Valves

An EEZ-ON

®

valve allows a gradual

buildup of downstream air pressure after

the supply is turned on. Rate of buildup

is adjustable. This controlled action lets

cylinders move slowly and more safely

into normal working positions.

A 3/2 EEZ-ON

®

valve

which has a shutoff-and-

exhaust feature is also

available.

Flow Control Valves

A ROSS flow control valve provides a high

air flow rate into a cylinder, and a precisely

controlled flow rate out of the cylinder. The

adjustable flow can range from near zero

to full flow. A non-rising adjustment knob

turns clockwise to reduce controlled flow.

Flow control valves in

other configurations

are also available

from ROSS.

L-O-X

®

Valves

A ROSS L-O-X

®

valve is an energy isolation valve,

generally the first valve in the air supply line. Air

can be shut off with a push of the red handle, and

downstream air is exhausted at the same time. For

safety, the handle should be padlocked in the closed

position when system maintenance

is being performed.

The manually controlled

L-O-X

®

valve is shown here,

but piloted models to control

the flow of air remotely are

also available.

Port Flow Control Avg. C

v

Size Model Numbers (Fully open)

1/4 1968E2007 2.3

3/8 1968E3007 2.6

1/2 1968E4007 7.5

3/4 1968E5007 8.3

1 1968E6007 17

1¼ 1968E7007 22

Port 2/2 Model Avg.

Size Number C

v

1/4 2781A2007 2.3

3/8 2781A3007 3.8

1/2 2781A4017 4.0

1/2 2781A4007 7.7

3/4 2781A5007 9.0

1 2781A6017 9.0

1 2781A6007 24

1¼ 2781A7007 29

1½ 2781A8017 29

ROSS

®

Port Sizes L-O-X

®

Valve Avg. C

v

In-Out Exh. Model Numbers In-Out Out-Exh

1/4 1/4 Y1523C2002 1.9 1.9

3/8 3/8 Y1523C3012 2.5 2.6

3/8 3/4 Y1523C3002 6.0 8.0

1/2 3/4 Y1523C4002 7.1 8.3

3/4 3/4 Y1523C5012 8.6 9.5

3/4 1¼ Y1523C5002 13 12

1 1¼ Y1523C6002 13 14

1¼ 1¼ Y1523C7012 20 14

1½ 2 Y1523C8002 38 47

2 2 Y1523C9012 38 47