TrustedTM PD-T8433 TrustedTM TMR Isolated 4-20 mA Analogue Input Module – 20 Channel Introduction TM The Trusted TMR Isolated 4-20 mA Analogue Input module interfaces to 20 current loop transmitters. Each channel provides independent high voltage galvanic isolation from system ground, as well as with respect to the other channels on the module. When used in conjunction with the T8833 Field Termination Assembly (FTA), the isolation barrier is powered from the current loop signal itself.

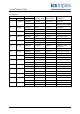

TrustedTM Module T8433 Issue Record Issue Number Date Revised by Technical Check Authorised by Modification 5 June 05 J W Clark G Creech R Cockman Reformat Sect 3.2.

TrustedTM Module T8433 This page is intentionally blank Issue 11 Apr 10 PD-T8433 3

TrustedTM Module T8433 Table of Contents 1. Description ...................................................................................................................................8 1.1. Isolated Input Field Termination Unit (IIFTU).............................................................................10 1.2. Input Field Interface Unit (IFIU) .................................................................................................10 1.3. Host Interface Unit (HIU) ...............

TrustedTM Module T8433 5.6. Cold Start ...................................................................................................................................30 5.7. Input Channel Calibration Check ...............................................................................................31 5.8. Transfer between Active and Standby Modules ........................................................................31 6. Specifications........................................................

TrustedTM Module T8433 Notice The content of this document is confidential to ICS Triplex Technology Ltd. companies and their partners. It may not be given away, lent, resold, hired out or made available to a third party for any purpose without the written consent of ICS Triplex Technology Ltd. This document contains proprietary information that is protected by copyright. All rights are reserved.

TrustedTM Module T8433 Revision and Updating Policy All new and revised information pertinent to this document shall be issued by ICS Triplex Technology Ltd. and shall be incorporated into this document in accordance with the enclosed instructions. The change is to be recorded on the Amendment Record of this document.

TrustedTM Module T8433 1. Description TM The TMR Isolated 4-20 mA Analogue Input module is a member of the Trusted range of Input/Output TM (I/O) modules. All Trusted I/O modules share common functionality and form. At the most general level, all I/O modules interface to the Inter-Module Bus (IMB) which provides power and allows TM communication with the Trusted TMR Processor. In addition, all modules have a field interface that is used to connect to module specific signals in the field.

TrustedTM Module T8433 TM Figure 2 shows a simplified functional block diagram of the Trusted module in a typical installation. 4-20 mA Isolated Analogue Input FTA VPOWER[1] V1+ DISTANT FIELD DEVICE V1- COMMON[1] 4-20 m A VSENSE[1] FIELD CABLE VPOWER[20] V20+ DISTANT FIELD DEVICE V20- COMMON[20] 4-20 m A VSENSE[20] FIELD CABLE 250 VRMS WORKING VOLTAGE T8833 FIELD TERMINATION ASSEMBLY 2.

TrustedTM Module T8433 1.1. Isolated Input Field Termination Unit (IIFTU) The Isolated Input Field Termination Unit (IIFTU) is the I/O module sub-assembly containing the field connector and the TMR isolation amplifiers. The IIFTU connects the isolated field signals into the TMR isolation amplifier array and onto the three IFIU slices. Each isolation amplifier slice in the array obtains its operating power from the 4-20 mA current loop input signal itself.

TrustedTM Module T8433 1.3. Host Interface Unit (HIU) The HIU is the point of access to the Inter-Module Bus (IMB) for the module. It also provides power distribution and local programmable processing power. The HIU is the only section of the I/O module TM to directly connect to the IMB backplane. The HIU is common to most Trusted I/O module types and has type dependent and product range common functions. Each HIU contains three independent slices, referred to as A, B, and C.

TrustedTM Module T8433 1.5. Line Monitoring Thresholds The module determines the contact state and line fault status by comparing the input current level to four user programmed thresholds and two fixed (minimum and maximum) thresholds. Hysteresis is provided on the thresholds by up-scale and downscale values, corresponding to the thresholds for increasing and decreasing values respectively. Default Input Channel State Line Fault Status Over-range 6 1 High-High 5 threshold values (mA) Tmax 24.

TrustedTM Module T8433 1.6. Housekeeping The input module automatically performs local measurements of several on-board signals that can be used for detailed troubleshooting and verification of module operating characteristics. Measurements are made within each slice’s HIU and FIU. 1.7. Fault Detection and Testing From the IMB to the field connector, the input module contains extensive fault detection and integrity testing. As an input device, all testing is performed in a non-interfering mode.

TrustedTM Module T8433 2. Installation 2.1. Module Insertion/Removal CAUTION: The module contains static sensitive parts. static handling precautions must be observed. Specifically ensure that exposed connector pins ARE NOT TOUCHED. Under no circumstances should the module housing BE REMOVED. Before installation, visually inspect the module for damage. Ensure that the module housing appears undamaged and inspect the I/O connector at the back of the module for bent pins.

TrustedTM Module T8433 2.3.

TrustedTM Module T8433 2.4. TrustedTM Module Polarisation/Keying. TM All Trusted Modules have been Keyed to prevent insertion into the wrong position within a chassis. The polarisation comprises two parts. The module and the associated field cable. Each module type has been keyed during manufacture.

TrustedTM Module T8433 3. Application 3.1. Module Configuration There is no configuration required to the physical input module. All configurable characteristics of the module are performed using tools on the EWS and become part of the application or system.ini file that is loaded into the TMR Processor. The TMR Processor automatically configures the input module after applications are downloaded and during Active/Standby changeover.

TrustedTM Module T8433 OEM Parameter Description Notes TICS_CHASSIS The number of the TM Trusted Chassis where the primary I/O module is installed The Trusted Controller Chassis is 1, TM and Trusted Expander Chassis are 2 to 15 TICS_SLOT The slot number in the chassis where the primary I/O module is installed The I/O module slots in the Trusted Controller chassis are numbered from 1 to 8.

TrustedTM Module T8433 3.2.2. Rack 2: STATE This board provides the majority voted numerical input state. This indicates within which threshold band the field input is in and module channel fault status.

TrustedTM Module T8433 3.2.3. Rack 3: AI The AI board returns the field loop current at the input. Channel Description 1 Field input channel 1 current 2 Field input channel 2 current 20 Field input channel 20 current 21 Field input channel 1 redundant current 40 Field input channel 20 redundant current Table 8 Rack 3: AI descriptions The current is the median value taken from the triplicated module.

TrustedTM Module T8433 3.2.4. Rack 4: THRSHOUT This board allows the current thresholds for an analogue input channel to be read or written by the application. The application can write new thresholds in the THRSHOUT board for a particular channel, and it can read the current thresholds from the THRSHIN board, under control of a channel in the THRSHOUT board. Channel Description 1 Write the threshold data for a particular input channel on channels 3 to 11 to the module.

TrustedTM Module T8433 3.2.6. Rack 6: DISCREP Channel Description 1 Discrepancy status inputs 1 to 16 2 Discrepancy status inputs 17 to 32 3 Discrepancy status inputs 33 to 40 Table 12 Rack 6: DISCREP bit descriptions Each of the words reports the discrepancy status of 16 input channels. The corresponding bit within the word is set to ‘1’ when a discrepancy condition is detected on that input channel’s input state (rack 2).

TrustedTM Module T8433 3.2.7.

TrustedTM Module T8433 Each input within the housekeeping rack is reported as an integer. In general, the application engineer will not normally require these inputs. They are provided to aid fault finding and diagnosis and may be used for reporting and display purposes. If a slice is Fatal, then all reported housekeeping inputs are set to zero. 3.2.8.

TrustedTM Module T8433 The FCR Status channel reports the fault status of the active and standby modules.

TrustedTM Module T8433 4. Operation 4.1. Front Panel Status LEDs on the front of the module provide visual indications of the module’s operational status and field input status. Each LED is a tri-colour LED of which for normal operation, only two colours are used; red and green. Located at the top and bottom of each module is an ejector lever that is used to remove the module from the chassis. Limit switches detect the open/closed position of the ejector levers.

TrustedTM Module T8433 4.2. Module Status LEDs There are six module status LEDs on the module front panel; three Healthy, one Active, one Standby, and one Educated. The Healthy indicators are controlled directly by each module slice. The Active, Standby, and Educated indicators are controlled by the FPU. The FPU receives data from each of the module slices. The FPU performs a 2-oo-3 vote on each data bit from the slices and sets the indicators accordingly.

TrustedTM Module T8433 4.3. I/O Status LEDs There are 20 input channel status LEDs on the module front panel, one for each field input. These indicators are controlled by the FPU. The FPU receives data from each of the module slices. The FPU performs a 2-oo-3 vote on each data bit from the slices and sets the indicators accordingly. The input status LED mode is dependent upon the voltage level of the field I/O signal.

TrustedTM Module T8433 5. Fault Finding and Maintenance 5.1. Fault Reporting Input module faults are reported to the user through visual indicators (LEDs) on the front panel of the module. Faults are also reported via status variables which may be automatically monitored in the application programs, and external system communications interfaces. There are generally two types of faults that must be remedied by the user; external wiring and module faults.

TrustedTM Module T8433 5.4. Companion Slot TM For a Companion Slot configuration, two adjacent slots in a Trusted Chassis are configured for the same input module function. One slot is the primary slot and the other a unique secondary (or spare) TM slot. The two slots are joined at the rear of the Trusted Chassis with a double-wide I/O Interface Cable that connects both slots to common field wiring terminations.

TrustedTM Module T8433 5.7. Input Channel Calibration Check It is recommended that you carry out a check on the input channel calibration. This check will detect long term drift and any inaccuracy as a result.

TrustedTM Module T8433 Under normal conditions, an active/standby changeover will only occur if the new active module is fault-free. Under some circumstances, it is desirable to be able to force a changeover to a known faulted module. This can be accomplished by opening the Module Removal switches on the currently active module and pressing the push-button reset on the TMR Processor. This will force the changeover to proceed even if the new active module is not fault free.

TrustedTM Module T8433 6. Specifications System Supply Voltage Range 20 to 32Vdc Number of Inputs 20 Channels Input Signal Current Range (with T8833 FTA) 2 to 22 mA minimum useable range Safety Accuracy +/- 1% of full scale (default threshold above which 0x70nn series slice discrepancy faults are raised) Calibration Accuracy 0.08% Recommended input channel calibration check interval 2 years Channel to Channel Crosstalk -60 dB minimum Resolution 3.

TrustedTM Module T8433 Self-Test Interval 2 minutes Operating Temperature -5°C to 60°C (23°F to 140°F) Non-operating Temperature -25°C to 70°C (-13°F to 158°F) Temperature change 0.5ºC/min Operating Humidity 5 – 95% RH non-condensing Environmental Specifications Refer to Document 552517 Dimensions Height Width Depth 266mm (10.5ins) 31mm (1.2ins) 303mm (12ins) Weight 1.221kg (2.7lbs) Real Time Clock Resolution 100µSec Note 1.) FTA sense resistor errors may add up to an additional +/- 0.