Owner's manual

Table Of Contents

- MP-IN003C-EN-P — April 2003

- Front Cover

- Catalog Numbers

- Table of Contents

- Receiving and Storage

- Environmental Ratings

- Motor Catalog Number Identification

- Before You Install the Motor

- Installing Your Motor

- Connector Data

- Mounting Dimensions

- Housing and Output Flange Connections

- Motor Load Force Ratings

- Holding Brake

- Cables and Connector Kits

- Gear Lubricant

- Related Documentation

- Back Cover

- Web Links

MP-Series Integrated Gear Motor Installation Instructions 29

Publication MP-IN003C-EN-P — April 2003

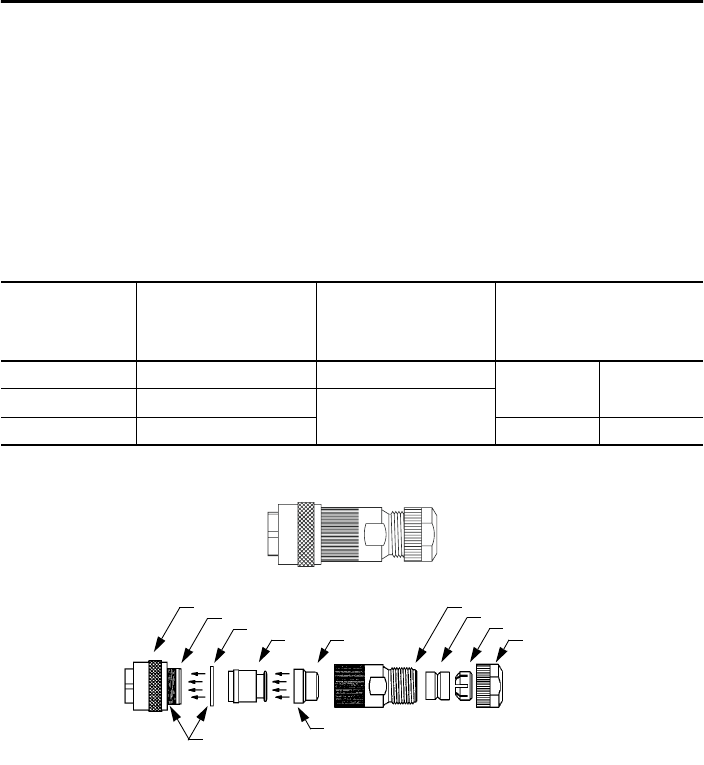

If you choose to build your own cables, the following connector kits are

available for MP-Series Integrated Gear Motors. These solder-type

connectors mate with the motor-mounted connectors and provide

environmental sealing with shield termination.

Each connector kit includes the requisite number and size of solder-type

contact pins, a connector housing, and a connector backshell. As an

example, finished and exploded views of the connector kit are shown

below.

Gear Lubricant

Gear units are permanently lubricated at the factory.

Catalog Number Connector

Type

Accepts

Wire Gauge

1

Accepts

Cable Diameter Gauge

mm

2

(AWG)

mm

2

(in.)

2090-MPPC-S Power - Straight 2.5-4.0 (14-12) 7.9-12.4 (0.31-0.49)

2090-MPFC-S Feedback - Straight 0.08-2.5 (28-14)

2090-MPBC-S Brake - Straight 4.3-7.4 (0.17-0.29)

1

Refer to your drive’s installation manual for recommended wire gauges.

Clamp Nut

Cable Clamp Ring

Sealing Grommet

EndbellConnector Coupling Ring

Bushing

Snap Ring Cone

onto Bushing

Install O-Ring

on groove in

Connector Housing

Ring Cone

O-Ring

Connector Housing