Owner's manual

Table Of Contents

- Front Cover

- Important User Information

- Summary of Changes

- Table of Contents

- Introduction

- About the Drive

- Identifying the Drive by Cabinet Assembly ID Number

- LiquiFlo 2.0 Drive Component Locations

- Identifying the Power Module by Model Number

- AC Line I/O Board Description (Frame 3 Only)

- Standard I/O Board Description (Frame 3 Only)

- Combined I/O Board Description (Frame 4 Only)

- DPI Communication Ports

- Optional Equipment

- Planning the Installation

- Mounting The Power Module and Grounding the Drive

- Installing Input and Output Power Wiring

- Completing the Installation

- Using the Start-up Routines

- Programming Basics

- Parameter Descriptions

- Troubleshooting the Drive

- Verify that the DC Bus Capacitors are Discharged Before Servicing the Drive

- Determining Drive Status Using the Status LEDs

- About Alarms

- About Faults

- Diagnostic Parameters

- Common Symptoms and Corrective Actions

- Replacement Parts

- Board Replacement, Firmware Setup Procedures

- Troubleshooting the Drive Using the OIM

- Checking the Power Modules with Input Power Off

- Technical Specifications

- Using the OIM

- Installing and Removing the OIM

- Display Description

- OIM Menu Structure

- Powering Up and Adjusting the OIM

- Selecting a Device in the System

- Using the OIM to Program the Drive

- Monitoring the Drive Using the Process Display Screen on the OIM

- Displaying and Changing the OIM Reference

- Customizing the Process Display Screen

- Customizing the Function Keys

- Controlling the Drive From the OIM

- LiquiFlo 2.0 Drive Frame 3 Wiring Diagrams

- LiquiFlo 2.0 Drive Frame 4 Wiring Diagrams

- Index

- Back Cover

30 Rockwell Automation Publication D2-3518-3 - May 2013

Chapter 2

Digital Outputs

The combined I/O board provides two user-configurable digital outputs, using

connector positions designated DO1 and DO2. These two digital outputs are

configured using inverter parameters Digital Out1 Sel through Digital Out2

OffTime (380...387).

The combined I/O board contains six special purpose digital outputs, using

connector positions designated DO3...DO8. The state of these six outputs can be

changed by writing to inverter parameter Appl Digital Out (30).

All eight digital output devices are form C relays capable of switching 250V AC

at 8 A, or 30V DC at 8 A.

The combined I/O board also contains dedicated terminals for driving the shunt

trip circuit.

Analog Inputs

The combined I/O board provides two user-configurable analog inputs.

Configure the inputs using inverter parameters Anlg In Config through Analog

In 2 Loss (320...327). Each analog input has two modes: voltage-sensing (input

senses -10 V...10 V) and current-sensing (input senses 0 mA...20 mA). Separate

terminals on the standard I/O board are used for each mode.

The mode for both inputs are selected via inverter parameter Anlg In Config

(320). If the bit corresponding to a particular analog input is set to 1, then the

analog input is in current-sensing mode; if set to 0 it is in voltage-sensing mode.

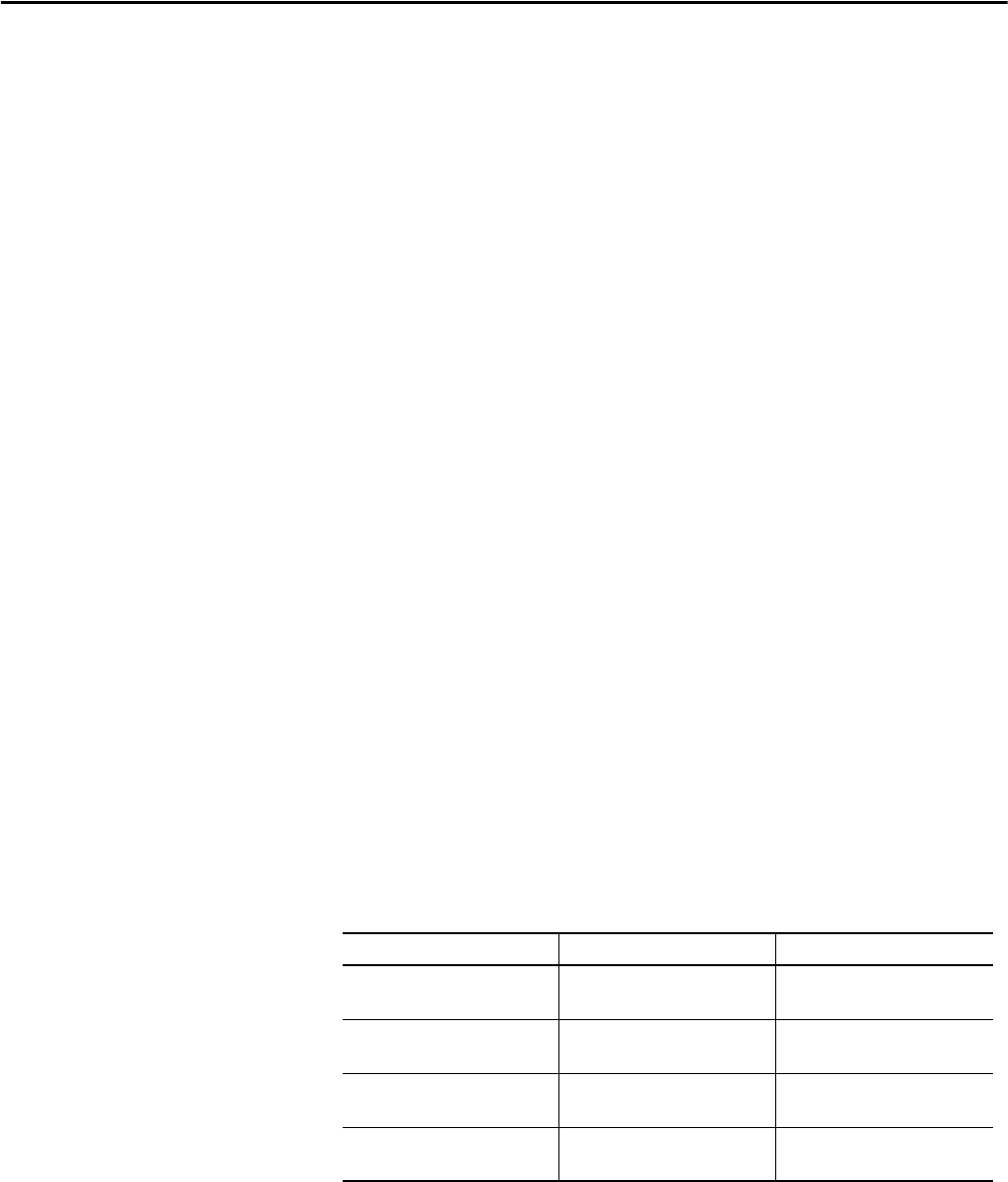

The following table describes the correspondence between the mode of each

user-configurable analog input and the combined I/O board terminals that

should be used.

Input and Mode Paramter 320 Setting Combined I/O Board Designator

Analog input 1,

voltage-sensing

Bit 0 = 0 AI1

Analog input 1,

current-sensing

Bit 0 = 1 AI2

Analog input 2,

voltage-sensing

Bit 1 = 0 AI3

Analog input 2,

current-sensing

Bit 1 = 1 AI4