Owner's manual

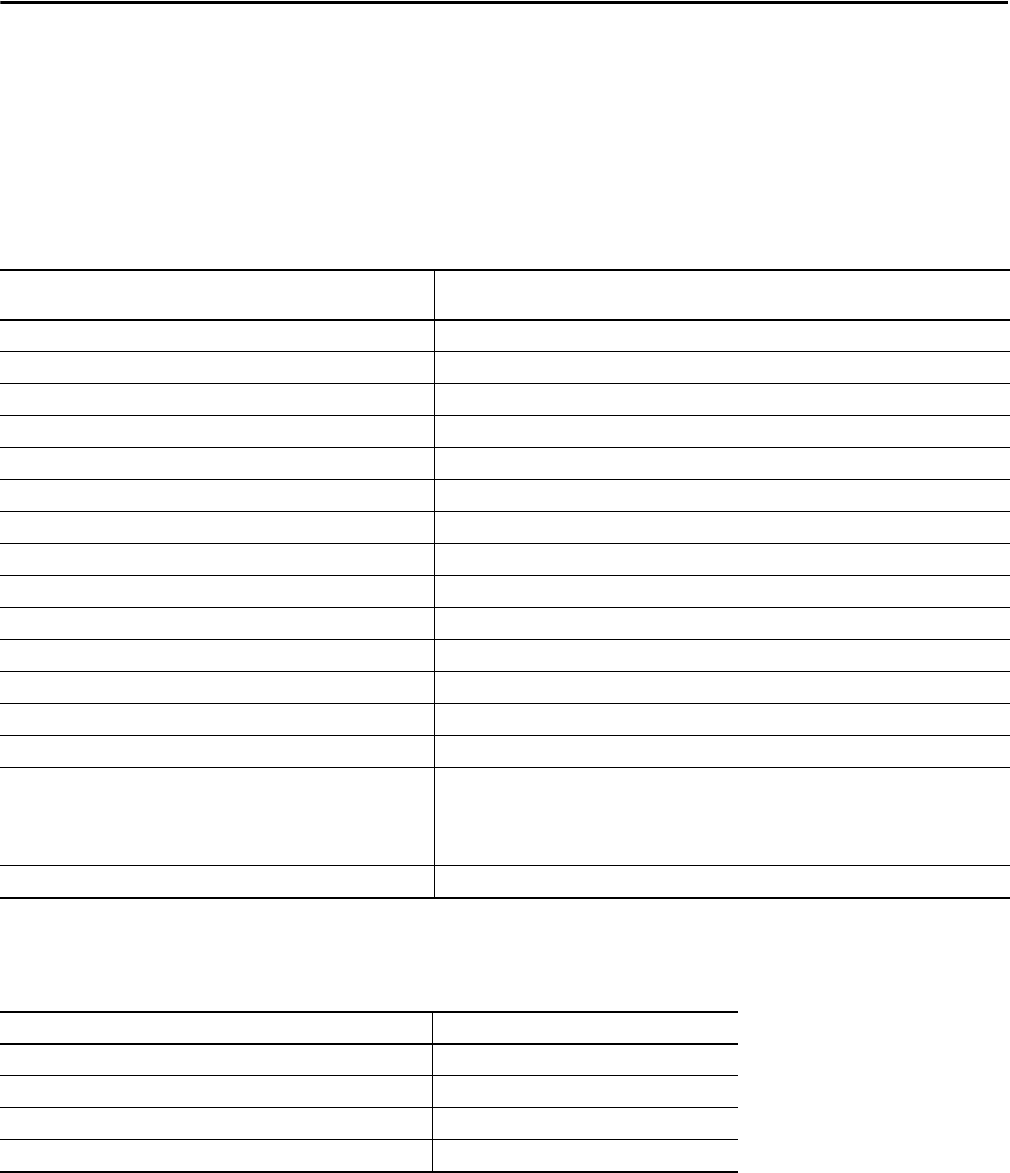

Table Of Contents

- Front Cover

- Important User Information

- Summary of Changes

- Table of Contents

- Introduction

- About the Drive

- Identifying the Drive by Cabinet Assembly ID Number

- LiquiFlo 2.0 Drive Component Locations

- Identifying the Power Module by Model Number

- AC Line I/O Board Description (Frame 3 Only)

- Standard I/O Board Description (Frame 3 Only)

- Combined I/O Board Description (Frame 4 Only)

- DPI Communication Ports

- Optional Equipment

- Planning the Installation

- Mounting The Power Module and Grounding the Drive

- Installing Input and Output Power Wiring

- Completing the Installation

- Using the Start-up Routines

- Programming Basics

- Parameter Descriptions

- Troubleshooting the Drive

- Verify that the DC Bus Capacitors are Discharged Before Servicing the Drive

- Determining Drive Status Using the Status LEDs

- About Alarms

- About Faults

- Diagnostic Parameters

- Common Symptoms and Corrective Actions

- Replacement Parts

- Board Replacement, Firmware Setup Procedures

- Troubleshooting the Drive Using the OIM

- Checking the Power Modules with Input Power Off

- Technical Specifications

- Using the OIM

- Installing and Removing the OIM

- Display Description

- OIM Menu Structure

- Powering Up and Adjusting the OIM

- Selecting a Device in the System

- Using the OIM to Program the Drive

- Monitoring the Drive Using the Process Display Screen on the OIM

- Displaying and Changing the OIM Reference

- Customizing the Process Display Screen

- Customizing the Function Keys

- Controlling the Drive From the OIM

- LiquiFlo 2.0 Drive Frame 3 Wiring Diagrams

- LiquiFlo 2.0 Drive Frame 4 Wiring Diagrams

- Index

- Back Cover

Rockwell Automation Publication D2-3518-3 - May 2013 233

Appendix A

Technical Specifications

Service Conditions

Environmental Conditions

AC Line Distribution System Capacity (maximum) for 480V AC Units Symmetrical fault current capacity: 85,000 A

Short circuit rating if a circuit breaker is used instead of fuses: 65,000 A (optional 100,000 A)

Control Method Sinusoidal pulse-width-modulated (PWM)

Displacement Power Factor

≥0.99

Line Frequency 50/60 Hz (

±2 Hz)

Line Voltage Variation -10...10%

Motor Lead Lengths 76 m (250 ft) total

Remote Operator Control Wire Length Up to 1 m (3 ft) from the drive

Analog Speed Reference Resolution 1/4096 (12 bits) 0.025%

Acceleration Adjustment Range 0.1...100.0 seconds (within the ability of current)

Carrier Frequency 2 kHz, 3 kHz, or 4 kHz (software-selectable)

Current Limit Adjustment 25...150% of drive rated amps

Service Factor 1.0

Speed Adjustable Range From 0 Hz to maximum speed

Speed Regulation Motor slip dependent

Speed Reference Resolution 0.01 with OIM,

±32767 counts with a network reference

Assembly Max Air Heat Load

(Heat Dissipated Into Surrounding Air, approx)

LF2 480V AC Input, 405 A output = approx 1800 W

LF2 480V AC Input, 608 A output = approx 2700 W

LF2 480V AC Input, 900 A output = approx 4000 W

LF2 480V AC Input, 1215 A output = approx 5300 W

Max Input Voltage Imbalance Service factor = 1.0

Condition Specification

Operating Temperature (inside NEMA/UL Type 1 enclosure) 0...+55 °C (32...131 °F)

Operating Temperature (outside NEMA/UL Type 1 enclosure) 0...40 °C (32...104 °F)

Storage Temperature (ambient) −40...65 °C (−40...149 °F)

Humidity 5...95% (non-condensing)