User Manual Instruction Manual

Wiring Requirements for the Drive

4-5

4.2 Control and Signal Wiring

4.3 Meeting Encoder Specifications

GV6000 AC drives can utilize an encoder for closed loop operation. Encoder

specifications are provided in table A.6. Drives set up for V/Hz or SVC regulation can

utilize an encoder for closed loop speed regulation, but it is not required.

!

ATTENTION: Verify the voltage rating of the I/O Interface board before

wiring any user devices. Failure to observe this precaution could result

in damage to, or destruction of, the equipment.

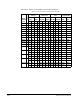

Table 4.2 – Recommended Signal and Control Wire

Signal Type Wire Type(s) Description

Minimum

Insulation Rating

Recommended Signal Wire

Analog I/O Belden 8760/9460

(or equiv.)

0.750 mm

2

(18 AWG),

twisted pair, 100%

shield with drain

1

.

1.If the wires are short, contained within a cabinet and are not mixed with noisy circuits, the use of shielded

wire may not be necessary, but is always recommended.

300V, 75-90° C

(167-194

°F)

Belden 8770

(or equiv.)

0.750 mm

2

(18 AWG)

3-conductor, shielded

for remote pot only.

Encoder/

Pulse I/O

Belden 9728 (or equiv.)

0.196 mm

2

(24 AWG),

individually shielded.

0.750 mm

2

(18 AWG),

twisted pair, shielded.

EMC

Compliance

Refer to EMC Compliance in Section 2.4.

Recommended Control Wire for Digital I/O

Unshielded

Control

Per US NEC or applicable

national or local code

-300V,

60

°C (140°F)

Shielded

Control

Multi-conductor shielded

cable such as Belden

8770 (or equiv.)

0.750 mm

2

(18 AWG),

3-conductor, shielded.

Table 4.3 – Control Terminal Block Specifications

Name Frame Description

Wire Size Range

1

1.Maximum/minimum sizes that the terminal block will accept. These are not recommendations.

TorqueMax Min

I/O Terminal

Block

All Signal & Control

Connections

2.1mm

(14 AWG)

0.3 mm

(22 AWG)

0.6 N-m

(5.2 in-lb)

Encoder

Terminal Block

All Encoder Power &

Signal Connections

0.75 mm

(18 AWG)

0.196 mm

(24 AWG)

0.6 N-m

(5.2 in-lb)