Software Start-Up and Ref. Owner manual

Table Of Contents

- GV3000/SE AC General Purpose (V/Hz) and Vector Duty Drive, 1 - 20 HP, 230V AC Software Start-Up and Reference Manual D2-3387-5

- Important User Information

- Document Update

- Summary of Changes

- Table of Contents

- List of Figures

- List of Tables

- Preface

- Chapter 1 - Starting Up the Drive for Volts/Hertz Regulation

- Chapter 2 - Starting Up the Drive for Vector Regulation

- Chapter 3 - Using the Keypad/Display To Program, Monitor, and Control the Drive

- Chapter 4 - Programming Reference

- Chapter 5 - Troubleshooting the Drive Using Error Codes

- Appendix A - Alphabetical Listing of Parameters

- Appendix B - Record of User Parameter Settings

- Appendix C - Power Module-Dependent Parameter Default Values (230 V Series)

- Appendix D - Default Parameter Settings

- Appendix E - Configuring the Digital Inputs When the RMI Board Is Installed in the Drive

- Appendix F - Using the Terminal Strip Analog Input

- Appendix G - Drive Regulation Overview

- Back Cover / Publication D2-3387-5 July 2013

2-33

Starting Up the Drive for Vector Regulation

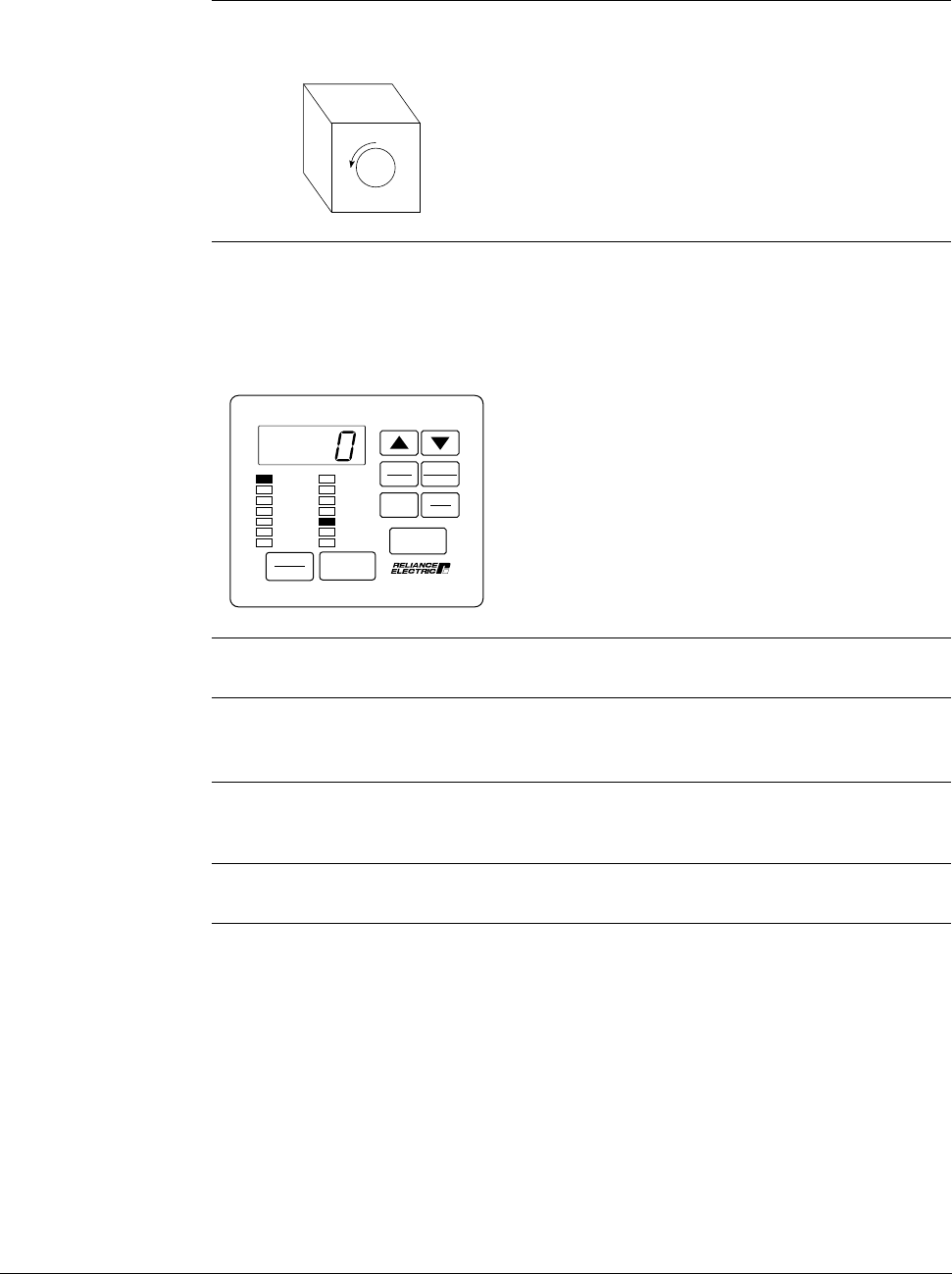

Step 10.8 Visually check that the motor rotates counter-clockwise (CCW) when

viewed from the driven motor shaft end.

CCW

Step 10.9

• If the rotation direction is NOT correct, press the STOP/RESET key and

continue with Step 10.10.

• If the rotation direction is correct, continue with Step 10.14.

AUTO

MAN

Forward

Reverse

PROGRAM

RUN

JOG

STOP

RESET

START

ENTER

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

When the STOP/RESET key is pressed, the

RUNNING LED turns off.

Step 10.10 Turn off and lock out or tag power to the drive.

Step 10.11 Verify that the DC bus capacitors are discharged. Refer to hardware

reference manual for this procedure.

Step 10.12 Switch any two of the motor leads (U, V, or W) and A and A NOT on

the encoder.

Step 10.13 Turn power on, and press the START key. Repeat Step 10.8.

Step 10.14 To make sure the drive is not inadvertently started, turn off and lock

out or tag power to the drive. Verify that the motor direction is

appropriate for the required machine direction, and then connect the

motor to the load.