User Manual

7-16

AutoMax Network Communication Option Board

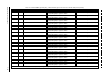

23 SPEED RAMP OUTPUT (P.199) Value of the speed reference signal immediately after the

speed loop

S-CURVE block

24

TAPER PERCENT (P.859) Percent reduction to be applied to the tension reference

from the taper function

25

TEN LOOP ERROR (P.834) Tension/current loop error signal after scaling

26

TEN PI KP OUT (P.879) Value of the tension loop pi proportional gain

27

TEN RAMP OUTPUT (P.842) Output of the tension major loop ramp block after

tension-to-current conversion

28

TEN TO CURRENT OUT (P.876) Output of the tension loop’s tension-to-current scaling

block

29 TRIM OUTPUT (P.197) Actual signal used to trim the selected speed loop

reference signal

30

UNWIND DIAMETER IN (P.828) Analog input signal (TB 16, 17) when DIAMTER/TAPER

SELECT (P.870) = DIAMETER

31 Indirect Register Status Bit-packed word containing information on

0 to 6 Offending register number. 0 = No error

7 to 12 Reserved

13 Error - Not found

14 Error - Output parameter

15 Network sync

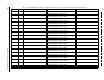

Table 7.12 – WebPak 3000 Register Map, Drop_3: Master Write Registers, FULL Connection. Tunable/Configurable Data (Drive Input Data)

Register Bit Parameter Name (Number) Description Settings

32 AutoMax Indirect Register 1 Value to be written to the parameter selected in the

corresponding Drop 2 register

33 AutoMax Indirect Register 2 Value to be written to the parameter selected in the

corresponding Drop 2 register

34 AutoMax Indirect Register 3 Value to be written to the parameter selected in the

corresponding Drop 2 register

Configurable data are read by the regulator approximately every 600 msec when Tune/Config Input Enable bit=1 and the drive is not running or jogging.

Table 7.11 – WebPak 3000 Register Map, Drop_3: Master Read Registers, FULL Connection. Runtime Signal Data (Drive Output Data) (Continued)

Register Bit Parameter Name (Number) Description Settings

Runtime signal data are updated by the regulator every 10 msec.