User Manual

7-12

AutoMax Network Communication Option Board

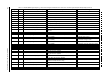

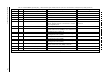

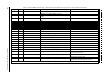

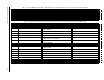

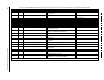

Table 7.9 – WebPak 3000 Register Map, Drop_2: Master Read Registers, FULL Connection. Tunable, Configurable, and Status Data (Drive Output Data)

Register Bit Parameter Name (Number) Description Settings

15 AC LINE PERIOD (P.393) AC line period as measured by the drive in

microseconds

16

ARMATURE BRIDGE POL (P.394) Indicates which bridge is currently active. OFF (forward bridge active; ON (reverse

bridge active)

17 ARMATURE DELTA (P.399) Armature firing angle in microseconds

18

CML FEEDBACK (P.397) CML feedback signal after scaling

19

CML RAMP INPUT TP (P.390) Current reference value to the CML ramp block

20

CML SPEED REFERENCE (P.391) Speed reference value to the current minor loop

21

CURRENT COMPOUND TP (P.293) Trim value that is subracted from the speed reference

based on motor load

22

DIAMETER ANALOG (P.821) Output of the diameter calculator scaled from zero at

empty core to 4095 at full roll diameter

23

DIAMETER RESET TP (P.829) State of the diameter reset signal

24

DRAW PERCENTAGE OUT (P.196) Product of the selectrd trim reference value and trim

range value

25

ENCODER KIT (P.798) Indicates if Pulse Encoder kit is installed and passed

diagnostics

INSTALLED; NOT INSTALLED; FAILED DIAGS

26 FIELD DELTA (P.588) Field firing angle indegrees 0 to 180 degree

27

FIELD ECONOMY ACTIVE (P.599) State of the field economy function ON; OFF

28 FLD CURRENT REGULATOR (P.586) Indicates if the Field Current Regulator kit is installed

and its rating

NOT INSTALLED; 4 AMP, 10 AMP, 20 AMP

29 INERTIA COMPENSATION (P.244) Output of the inertia compensation calculator

30

IR COMPENSATION TP (P.290) Level of IR compensation being subtracted from the

measured armature voltage

31

DIAMETER CALC OUTPUT (P.132) Value of the calculated roll diameter normalized at

1.000 at

EMPTY CORE DIAMETER (P.830)

Tunable, configurable, and status data are updated by the regulator approximately every 600 msec.