User Manual

FlexPak 3000 Drives: Alternate Register Map

6-1

CHAPTER 6

FlexPak 3000 Drives:

Alternate Register Map

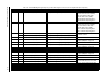

This section lists the alternate register map, which enables you to access most of the

FlexPak 3000 original register map functions plus some additional functions. The

alternate register map is organized so that commonly used functions are available in

Drop_1. It also offers a different set of options in Drop_1 than the original register

map.

The additional functions that are available through the alternate register map are:

• Winding functions: SPEED FEEDBACK GAIN (Drop_1, register 38) and UNDERWIND

ENABLE (Drop_1, register 32, bit 5) enable you to set up under- or overwinding and

set the gain of the speed loop feedback path for winding applications.

• Access to the speed loop PI reset and initial value. These parameters are SPD LOOP

PI INIT SEL (Drop_2, register 32), SPD LOOP PI INIT VAL (Drop_1, register 39), and SPD

LOOP PI RESET (Drop_1, register 32, bit 6).

• Process Error Parameter Number (Drop_1, register 27)

• NETW REGISTER MAP SEL (P.914) (Drop_1, register 29)

• RAMP STOP DECEL TIME (P.018) (Drop_2, register 33)

• INV FLT AVOID SEL (P.312) (Drop_2, register 43)

• TACH LOSS SCR ANGLE (P.608), (Drop_3, register 50)

• NEG CUR LIM INV EN (P.226) (Drop_3, register 53, bit 0)

• OCL PROP TRIM SELECT (P.813) (Drop_3, register 53, bit 1)

• OCL TYPE3 POSN REG EN (P.814) (Drop_3, register 53, bit 2)

• PHASE LOSS DETECT EN (P.609) (Drop_3, register 53, bit 3)

• STOP DECEL SELECT (P.122) (Drop_3, register 53, bit 4)

• CML REF LIMIT SELECT (P.311) (Drop_3, register 53, bit 6

• DIG IN 0 SELECT (P.428) (Drop_4, register 47)

Brief descriptions of parameters are in the register map tables. For detailed parameter

descriptions, refer to the

FlexPak 3000 DC Drive Software Reference Manual

.

!

ATTENTION:If you are using the alternate register map (NETW REGISTER

MAP SEL (P.914) set to ALTERNATE) and you change the control source

from

NETWORK, the parameters SPD LOOP PI INIT SEL, SPD LOOP PI INIT VAL,

and

SPD LOOP PI RESET are reset to their default values (0 for each). Make

sure these values are appropriate for your application before changing

the control source. Failure to observe this precaution could result in

severe bodily injury or loss of life.