User Manual Owner's manual

Table Of Contents

- Important User Information

- Preface

- Table of Contents

- About the Interface

- Overview

- Important Interface Considerations

- About the Interface

- Interface Features

- What the Interface Does

- Hardware/Software Compatibility

- Use of the Common Industrial Protocol (CIP)

- Understand the Producer/ Consumer Model

- Specify the Requested Packet Interval (RPI)

- Support of Data Connections

- Chapter Summary

- Install a Guardmaster EtherNet/IP Network Interface

- Configure the Interface for Your EtherNet/ IP Network

- Automation Controller Communications

- Troubleshoot the Interface

- EtherNet/IP Network Interface Specifications

- Interface Web Dialogs

- Configure the RSLinx Ethernet Communication Driver

- Tag Definitions

60 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Appendix D Tag Definitions

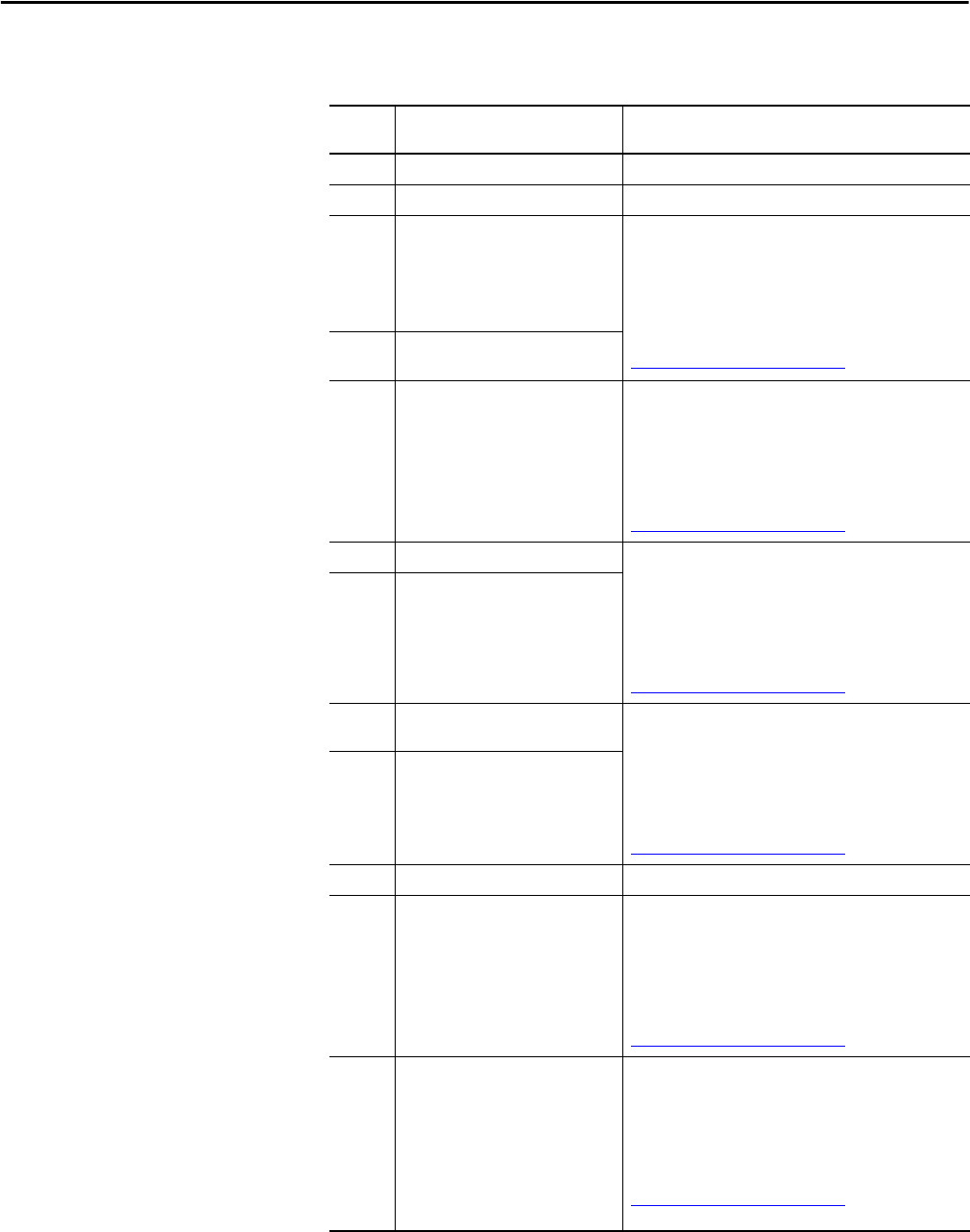

Table 12 - GSR GLP NonRecoverableFault_A and NonRecoverableFault_B Fault Codes

Fault

Code

Description Corrective Action

00H No fault None

03H Jitter fault

04H Proximity Sensor 1 (P12) stuck at High

fault: Potential damage or

misalignment of the Proximity Sensor

(e.g. exceeding maximum sensing

distance, both sensors detecting a

space).

Do one of the following:

• Check the alignment and functionality of the Proximity

Sensor.

• Power cycle the safety relay.

• Reconfigure the safety relay.

If the fault persists, contact your local Rockwell Automation

technical support representative. For contact information, see:

http://rockwellautomation.com/support

04H Proximity Sensor 2 (P22) stuck at High

fault.

06H Proximity Sensors cross fault. Do one of the following:

• Check connection of P12 and P22 against shorts to 24V or

0V and cross loop shorts.

• Power cycle the safety relay.

• Reconfigure the safety relay.

If the fault persists, contact your local Rockwell Automation

technical support representative. For contact information, see:

http://rockwellautomation.com/support

07H Self test of terminal 51 failed. Do one of the following:

• Check connection of 51 or L61 against shorts to 24V or 0V

and cross loop shorts.

• Power cycle the safety relay.

• Reconfigure the safety relay.

If the fault persists, contact your local Rockwell Automation

technical support representative. For contact information, see:

http://rockwellautomation.com/support

08H Self test of terminal L61 failed.

09H Proximity Input Fault: Both Proximity

inputs are Low simultaneously.

Do one of the following:

• Check the alignment and functionality of the Proximity

Sensors.

• Power cycle the safety relay.

• Reconfigure the safety relay.

If the fault persists, contact your local Rockwell Automation

technical support representative. For contact information, see:

http://rockwellautomation.com/support

0AH Proximity Input Fault: Both Proximity

inputs stuck at HIGH simultaneously.

0BH SPI compare fault

0CH Self test of Single Wire Safety outputs

L11, L61 fault

Do one of the following:

• Check connection of L11 or L61 against shorts to 24V or 0V

and cross loop shorts.

• Power cycle the safety relay.

• Reconfigure the safety relay.

If the fault persists, contact your local Rockwell Automation

technical support representative. For contact information, see:

http://rockwellautomation.com/support

0DH Current configuration does not agree

with the safety relay memory:

• Switch settings do not match

required initial configuration or

• X14 and X24 are connected to inputs

S12, S22 but they are configured as

safety outputs or

• L1 and 51 connection has changed

after configuration

Do one of the following:

• Change the switch settings to the correct values.

• Power cycle the safety relay.

• Reconfigure the safety relay.

If the fault persists, contact your local Rockwell Automation

technical support representative. For contact information, see:

http://rockwellautomation.com/support