Instruction Manual

Table Of Contents

- Front Cover

- Important User Information

- Where to Start

- Table of Contents

- Preface

- Chapter 1

- Chapter 2

- System Layout and Wiring

- Before You Begin

- What You Need

- Follow These Steps

- Planning Your ArmorStart Panel Layout and Wiring

- Wiring Your ArmorStart Controllers

- Connecting the DeviceNet ArmorConnect to Your ArmorStart Device

- AC Supply Considerations for Bulletin 284 Units

- Group Motor Installations For North American and Canadian Markets

- Cabling and Installation Guidelines

- DeviceNet Network Installation

- Electromagnetic Compatibility

- System Layout and Wiring

- Chapter 3

- ArmorStart DeviceNet Configuration

- Before You Begin

- What You Need

- Follow These Steps

- Open an Existing Project in RSLogix 5000 Software

- Configure the DeviceNet Network by Using RSNetWorx Software

- Add a Scanner Module to Your ControlLogix Project

- Generate ArmorStart Tags by Using the Tag Generator Tool

- Download Controller File and Test ArmorStart Tags

- ArmorStart DeviceNet Configuration

- Chapter 4

- Chapter 5

- Faceplate Logix Integration

- Before You Begin

- What You Need

- Follow These Steps

- Import the ArmorStart Add-On Instructions

- Reassign Add-On Instruction Input and Output Parameter Data Types

- Modify ArmorStart Add-On Instruction for Equipment Status Faceplate

- Integrate ArmorStart AOI into Your Application Program Routines

- Integrate Your ArmorStart Device Application

- Add Alarm Logic for Alarm History Faceplate

- Download the Project

- Faceplate Logix Integration

- Chapter 6

- Chapter 7

- ArmorStart System Application Guide

- Before You Begin

- What You Need

- ArmorStart System Overview Display

- ArmorStart Device Faceplate Overview

- ArmorStart Device Faceplate - Fault Indication View

- Last Fault, Fault Description, and Fault Action

- ArmorStart Device Faceplate - Configuration Status View

- ArmorStart Device Faceplate - Trending View

- ArmorStart Device Faceplate - Online Help Options

- ArmorStart System Application Guide

- Appendix A

- Logix Communication and Controller Configuration

- Configuring PC Communication

- Configure the EtherNet/IP Driver

- Load the Controller Firmware Serially

- Assign IP Addresses

- Ethernet Module Firmware Update Using ControlFLASH Utility

- Browse the EtherNet/IP Network Devices

- Load the Controller Firmware

- Create a New Project File in RSLogix 5000 Software

- Configure Your Ethernet Module

- Logix Communication and Controller Configuration

- Appendix B

- Appendix C

- Back Cover/Rockwell Support

Publication IASIMP-QS015C-EN-P - August 2011 53

System Layout and Wiring Chapter 2

AC Supply Considerations for Bulletin 284 Units

This section describes AC supply considerations for Bulletin 284 units.

Ungrounded and High-resistive Distribution Systems

Disconnect MOVs

To prevent device damage, the MOVs connected to ground must be disconnected if the device is installed on

an ungrounded and high resistive distribution system where the line-to-ground voltages on any phase could

exceed 125% of the nominal line-to-line voltage. To disconnect the MOVs, follow this procedure to remove

the jumper.

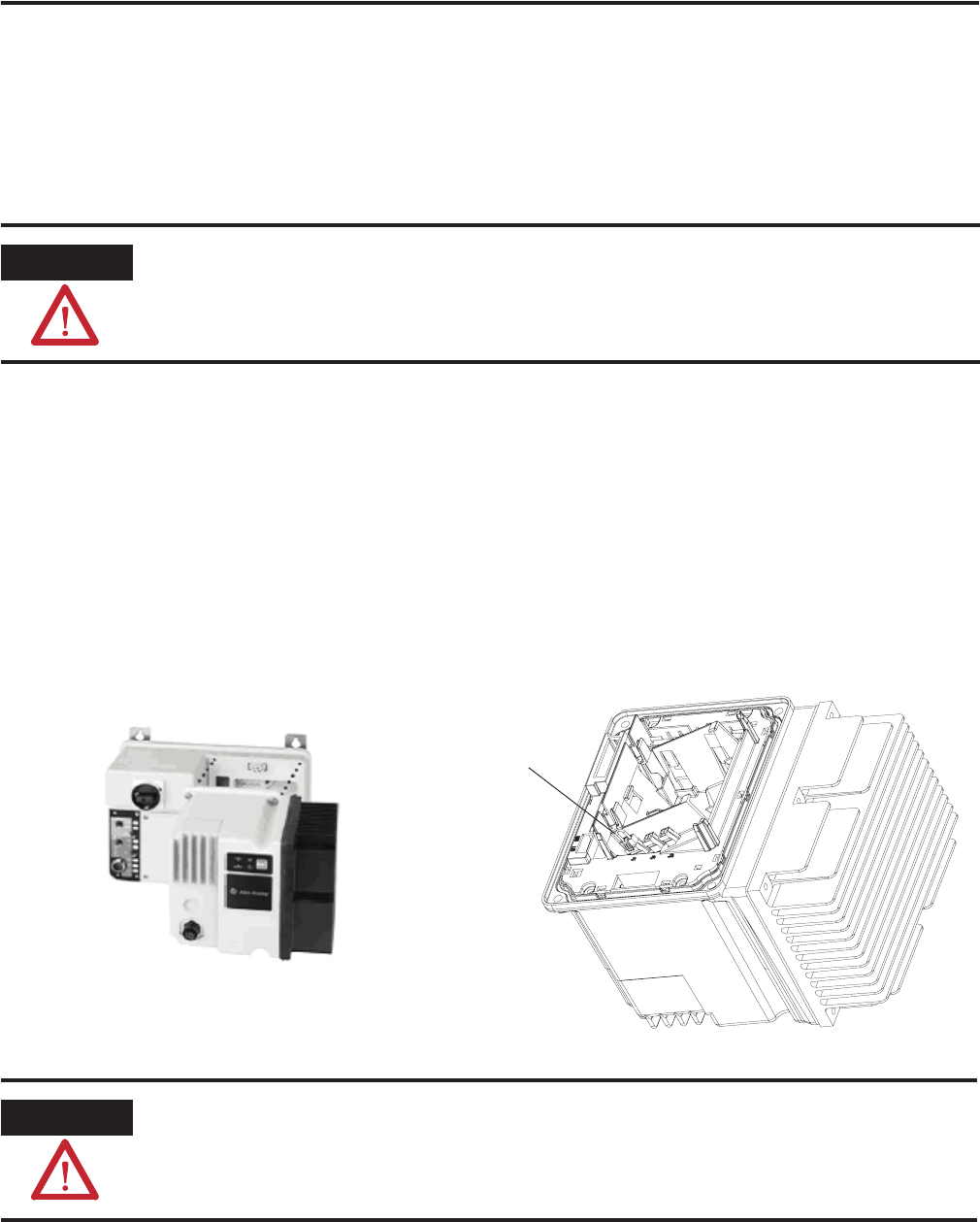

1. Loosen the four mounting screws before installing the Bulletin 284 device.

2. Unplug the started module from the base unit by pulling forward.

ATTENTION

The Bulletin 284 device contains protective metal oxide variables (MOVs) that are referenced to ground.

These devices should be disconnected if the Bulletin 284 device is installed on an ungrounded and

high-resistive distribution system.

ATTENTION

Do not remove this jumper if the unit is equipped with an EMI filter installed.

The EMI Filter option is required if the Bulletin 284 ArmorStart Distributed Motor Controller must be

CE-compliant. If the EMI Filter is selected, a 3 meter shielded 4-conductor cordset is provided as standard.

is option is only available with sensorless vector control.

Jumper