Instruction Manual

Table Of Contents

- Front Cover

- Important User Information

- Where to Start

- Table of Contents

- Preface

- Chapter 1

- Chapter 2

- System Layout and Wiring

- Before You Begin

- What You Need

- Follow These Steps

- Planning Your ArmorStart Panel Layout and Wiring

- Wiring Your ArmorStart Controllers

- Connecting the DeviceNet ArmorConnect to Your ArmorStart Device

- AC Supply Considerations for Bulletin 284 Units

- Group Motor Installations For North American and Canadian Markets

- Cabling and Installation Guidelines

- DeviceNet Network Installation

- Electromagnetic Compatibility

- System Layout and Wiring

- Chapter 3

- ArmorStart DeviceNet Configuration

- Before You Begin

- What You Need

- Follow These Steps

- Open an Existing Project in RSLogix 5000 Software

- Configure the DeviceNet Network by Using RSNetWorx Software

- Add a Scanner Module to Your ControlLogix Project

- Generate ArmorStart Tags by Using the Tag Generator Tool

- Download Controller File and Test ArmorStart Tags

- ArmorStart DeviceNet Configuration

- Chapter 4

- Chapter 5

- Faceplate Logix Integration

- Before You Begin

- What You Need

- Follow These Steps

- Import the ArmorStart Add-On Instructions

- Reassign Add-On Instruction Input and Output Parameter Data Types

- Modify ArmorStart Add-On Instruction for Equipment Status Faceplate

- Integrate ArmorStart AOI into Your Application Program Routines

- Integrate Your ArmorStart Device Application

- Add Alarm Logic for Alarm History Faceplate

- Download the Project

- Faceplate Logix Integration

- Chapter 6

- Chapter 7

- ArmorStart System Application Guide

- Before You Begin

- What You Need

- ArmorStart System Overview Display

- ArmorStart Device Faceplate Overview

- ArmorStart Device Faceplate - Fault Indication View

- Last Fault, Fault Description, and Fault Action

- ArmorStart Device Faceplate - Configuration Status View

- ArmorStart Device Faceplate - Trending View

- ArmorStart Device Faceplate - Online Help Options

- ArmorStart System Application Guide

- Appendix A

- Logix Communication and Controller Configuration

- Configuring PC Communication

- Configure the EtherNet/IP Driver

- Load the Controller Firmware Serially

- Assign IP Addresses

- Ethernet Module Firmware Update Using ControlFLASH Utility

- Browse the EtherNet/IP Network Devices

- Load the Controller Firmware

- Create a New Project File in RSLogix 5000 Software

- Configure Your Ethernet Module

- Logix Communication and Controller Configuration

- Appendix B

- Appendix C

- Back Cover/Rockwell Support

Publication IASIMP-QS015C-EN-P - August 2011 47

System Layout and Wiring Chapter 2

ArmorStart Device Wiring

Wiring in an industrial control application can be divided into three groups; power, control, and signal.

Follow these recommendations for physical separation between these to reduce the coupling effect:

• Minimum spacing between different wire groups in the same tray should be 16 cm (6 in.).

• Run wire outside an enclosure conduit or have shielding or armor with equivalent attenuation.

• Run different wire groups in separate conduits.

• Minimum spacing between conduits containing different groups should be 8 cm (3 in.).

The table provides power, control, ground wire capacity, and tightening torque requirements. The power,

control, ground, and safety monitor terminals accept a maximum of two-wire per terminal.

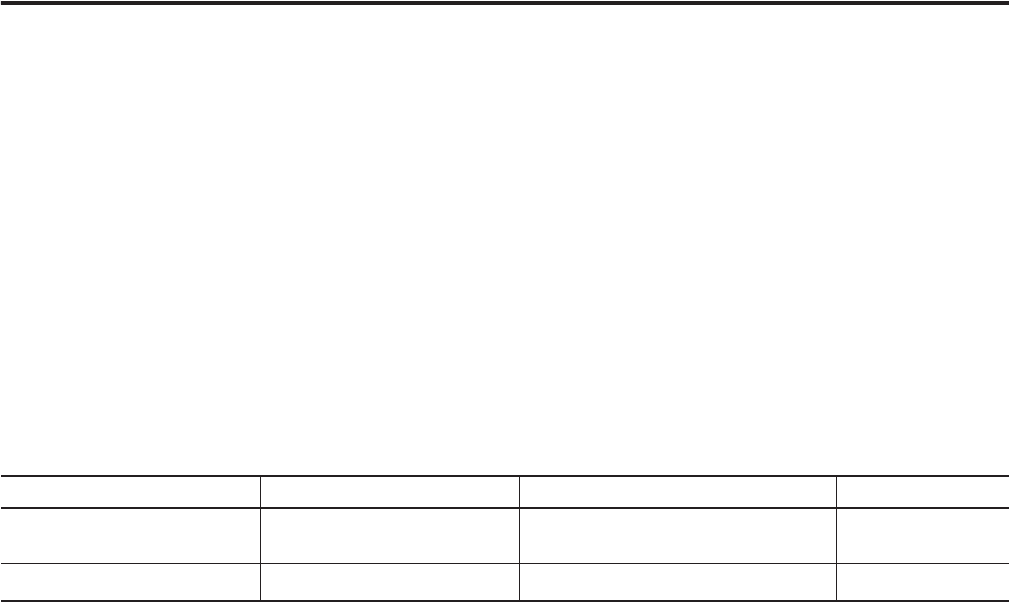

Power, Control, Safety Monitor Inputs, Ground Wire Size, and Torque Specifications

Terminal Type Wire Size Torque Wire Strip Length

Power and Ground Primary/secondary terminal

1.5...4.0 mm

2

(16...10 AWG)

Primary terminal - 1.2 N•m (10.8 lb•in.)

Secondary terminal - 0.5 N•m (4.5 lb•in.)

9 mm (0.35 in)

Control and Safety Monitor Inputs

1.0...4.0 mm

2

(18...10 AWG)

0.7 N•m (6.2 lb•in.) 9 mm (0.35 in.)