Instruction Manual

Table Of Contents

- PowerFlex 700S High Performance AC Drive - Phase II Control, Programming Manual

- Summary of Changes

- Table of Contents

- Preface

- Chapter 1 - Drive Start-Up

- Chapter 2 - Programming and Parameters

- Chapter 3 - Troubleshooting

- Appendix A - Human Interface Module Overview

- Appendix B - Application Notes

- Appendix C - Control Block Diagrams

- Appendix D - PowerFlex 700S Permanent Magnet Motor Specifications

- Appendix E - ATEX Approved PowerFlex 700S, Phase II Drives in Group II Category (2) Applications with ATEX Approved Motors

- Appendix F - History of Changes

- Index

- Back Cover

36 Rockwell Automation Publication 20D-PM001C-EN-P - July 2013

Chapter 2 Programming and Parameters

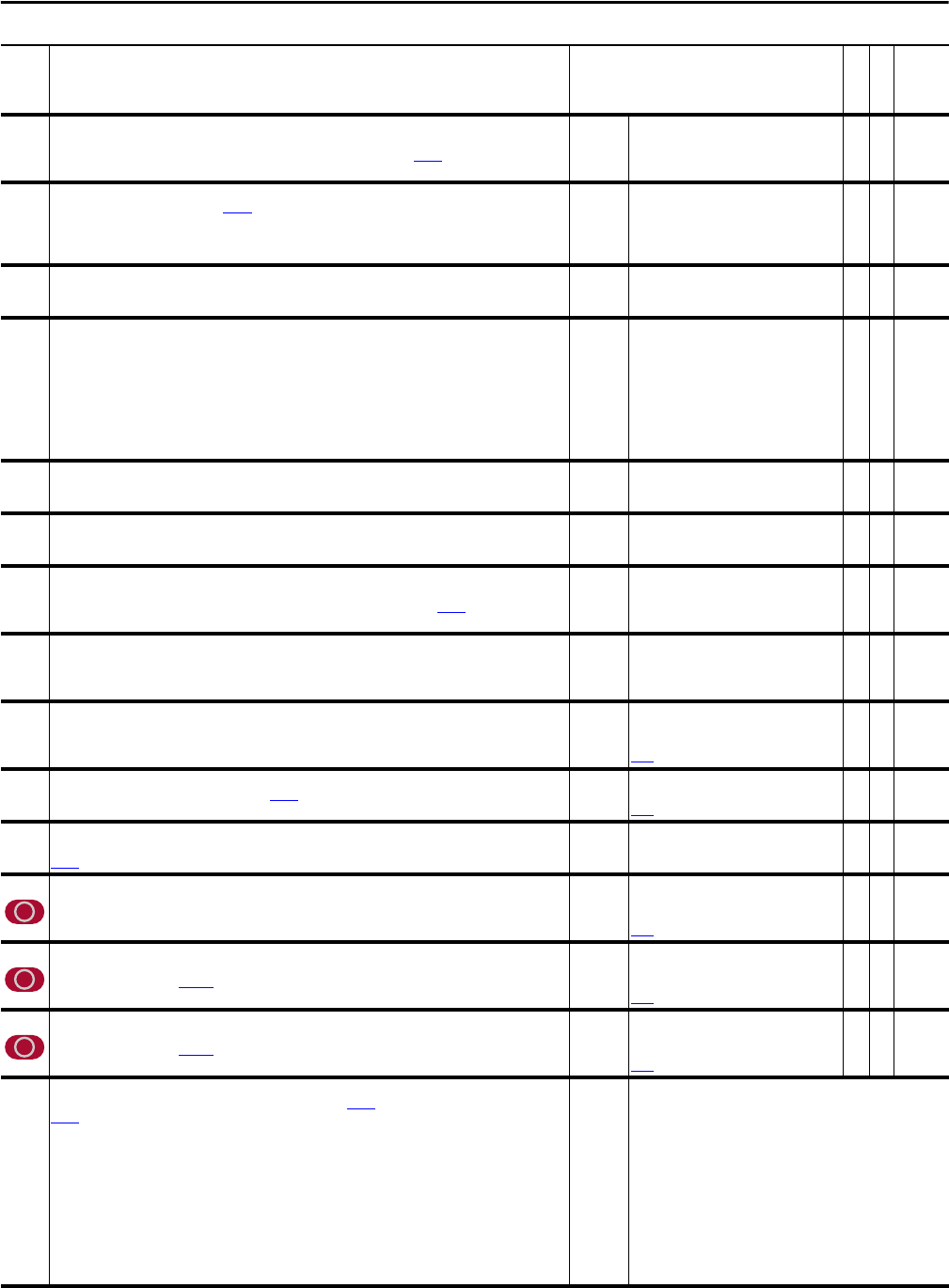

62 Virt Encdr Posit

A 32 bit pulse accumulator of the virtual encoder. The accumulated pulse count is equivalent to the hardware

accumulator of a real encoder. It accumulates at a rate of 4x the value placed in Par 61

[Virt Encoder EPR]. The

accumulator starts at zero upon position enable.

Default:

Min/Max:

0

-/+2147483648

RO 32-bit

Integer

63 Virt Encdr Dlyed

One sample period delayed output of Par 62 [Virt Encdr Posit]. Used in some applications to phase synchronize

position reference through SynchLink. The master is delayed one sample while the downstream drives update

their position references – then all drives sample position simultaneously. The downstream drives do not select a

delay.

Default:

Min/Max:

0

-/+2147483648

RO 32-bit

Integer

64 FricComp Spd Ref

Supplies a speed input to the Friction Compensation algorithm. This input is normally a speed reference from a

motion planner or ramped speed reference. It will trigger a torque feed forward response depending on its value.

Default:

Min/Max:

Units:

0.0000

-/+8.0000 P.U.

rpm

Y

RW Real

65 FricComp Setup

Enter or write a value to configure the friction compensation algorithm. This is a packed word of 3 digits. Each

digit has a possible selection of 10 levels.

• The least significant digit sets the speed threshold in intervals of 0.0005 P.U. speed.

• The next (middle) digit sets the hysteresis band for the “units” digit in intervals of 0.0005 P.U. velocity.

• The most significant digit sets the number of time steps from stick to slip, each step is 0.002 sec.

Example: Value = 524 means: 5 time steps between stick and slip, each of 0.002 sec. duration, 2 counts of

hysteresis or 0.001 pu_speed (each count is 0.0005 pu_speed), and 4 counts or 0.002 pu_speed is the trigger

threshold (each count is 0.0005 pu_speed).

Default:

Min/Max:

325

0/999

Y

RW 16-bit

Integer

66 FricComp Stick

The torque needed to break away from zero speed. By nature of friction, the break away sticktion will always be

greater than the running friction.

Default:

Min/Max:

Units:

0.1500

0.0000/8.0000

P. U .

Y

RW Real

67 FricComp Slip

The torque level to sustain very low speed – once “break away” has been achieved. By nature of friction, viscous

friction will always be less than sticktion.

Default:

Min/Max:

Units:

0.1000

0.0000/8.0000

P. U .

Y

RW Real

68 FricComp Rated

The torque needed to keep the motor running at base speed and with no process loading. The friction

compensation algorithm assumes a linear or viscous component of friction between Par 67 [FricComp Slip] and

Par 68 [FricComp Rated].

Default:

Min/Max:

Units:

0.2000

0.0000/8.0000

P. U .

Y

RW Real

69 FricComp Trq Add

The torque reference output of the Friction Compensation function. A value of 1.0 represents rated torque of the

motor.

Default:

Min/Max:

Units:

Scale:

0.0000

-/+8.0000 P.U.

P. U .

Motor P.U. Torque

RO Real

71 Filtered SpdFdbk

Displays the motor speed feedback value output from the feedback Lead/Lag filter.

Default:

Min/Max:

Units:

Scale:

0.0000

-/+14112.0000

rpm

Par 4 [Motor NP RPM] = 1.0 P.U.

RO Real

72 Scaled Spd Fdbk

Displays the product of the speed feedback and Par 73 [Spd Fdbk Scale]. This parameter is for display only.

Default:

Min/Max:

Scale:

0.0000

-/+2200000000.0000

Par 4 [Motor NP RPM] = 1.0 P.U.

RO Real

73 Spd Fdbk Scale

A user-adjustable scale factor (multiplier) for speed feedback. It is multiplied with speed feedback to produce

Par 72

[Scaled Spd Fdbk].

Default:

Min/Max:

1.0000

-/+2200000000.0000

Y

RW Real

74 Atune Spd Ref

Sets the maximum speed of the motor during the Flux current and inertia tests.

Default:

Min/Max:

Units:

Scale:

Par 4 x 0.8500

Par 4 x 0.1000/Par 4 x 1.0000

rpm

Par 4

[Motor NP RPM] = 1.0 P.U.

RW Real

75 Rev Speed Limit

Sets a limit on the speed reference in the negative direction. This value can be entered as a negative value or zero.

The maximum value equals Par 532

[Maximum Freq] x 0.95.

Default:

Min/Max:

Units:

Scale:

Par 4 x -1.2500

-8.0000/0.0000

rpm

Par 4

[Motor NP RPM] = 1.0 P.U.

RW Real

76 Fwd Speed Limit

Sets a limit on the speed reference in the positive direction. This value can be entered as a positive value or zero.

The maximum value equals Par 532

[Maximum Freq] x 0.95.

Default:

Min/Max:

Units:

Scale:

Par 4 x 1.2500

0.0000/8.0000

rpm

Par 4

[Motor NP RPM] = 1.0 P.U.

RW Real

77 Spd Ref TP Sel

Enter or write a value to select speed reference data displayed in Par 79 [Spd Ref TP Data] and

Par 78

[Spd Ref TP RPM].

Note: The values for options 7, 8, & 9 were changed to “Reserved” for firmware version 2.004.

Default:

Options:

0 =

0 =

1 =

2 =

3 =

4 =

5 =

6 =

7 =

8 =

9 =

10 =

11 =

“Zero”

“Zero” 12 = “S Crv Match”

“User Ref” 13 = “S Array size”

“Logic Select” 14 = “S Array Indx”

“Lgc Sel Ref” 15 = “Reserved”

“Ramp Spd Ref” 16 = “Scl Ext Trim”

“Ramp In” 17 = “Trim FiltOut”

“Filt Spd Ref” 18 = “Ref w/Trim”

“Reserved” 19 = “Amp Lim2 In”

“Reserved” 20 = “Amp LimStat2”

“Reserved” 21 = “Amp Lim2 Out”

“Amp Lim Stat” 22 = “FTD Ramp Out”

“Ramp Match” 23 = “Reserved”

No. Name

Description

Values

Linkable

Read-Write

Data Type