USER MANUAL

Table Of Contents

- 1791-6.5.1, Block I/O, User Manual

- Important User Information

- Summary of Changes

- Table of Contents

- 1 - Using This Manual

- 2 - Introducing Block I/O

- 3 - Installing Block I/O

- 4 - Configuring Your Block I/O for PLC Family Programmable Controllers

- 5 - Configuring Your Block I/O for SLC Controllers

- 6 - Troubleshooting

- A - Specifications

- Index

- Back Cover

Chapter

3

31

Installing Block I/O

In this chapter you will learn how to mount the block, connect the remote

I/O link, connect the input and output wiring to the block, and terminate

the remote I/O link.

Before installation, you must determine:

the number of blocks desired

the total distance of the installation

transmission rate desired

if external fuses are required

Refer to Table 3.A for acceptable combinations.

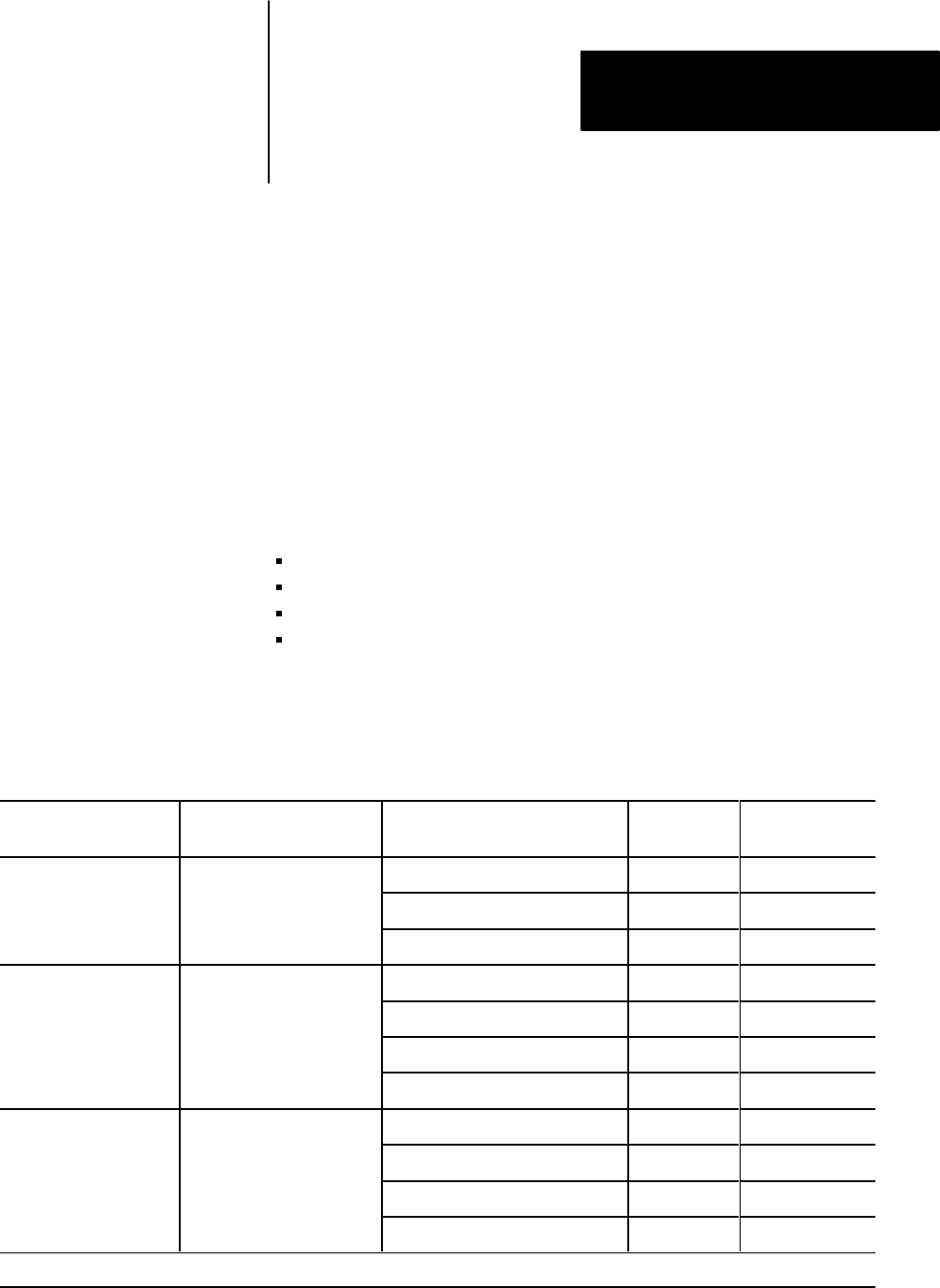

Table 3.A

Acceptable

Combinations of Processor and Block I/O

When using and Maximum Capacity

Baud Rate

Used

Maximum

Network Distance

PLC-2 family 16 blocks with 150 ohm terminator 57.6K 10,000 cable-feet

Any scanner module

28 blocks with 82 ohm terminator 57.6K 10,000 cable-feet

28 blocks with 82 ohm terminator 115.2K 5,000 cable-feet

PLC-3 family 16 blocks with 150 ohm terminator 57.6K 10,000 cable-feet

1775S4A, S4B, S5, SR

32 blocks with 82 ohm terminator 57.6K 10,000 cable-feet

1775 S4A

,

S4B

,

S5

,

SR

or SR5 module

32 blocks with 82 ohm terminator 115.2K 5,000 cable-feet

32 blocks with 82 ohm terminator 230.4K 2,500 cable-feet

PLC-5 family 16 blocks with 150 ohm terminator 57.6K 10,000 cable-feet

Note: PLC5250 requires a

32 blocks with 82 ohm terminator 57.6K 10,000 cable-feet

Note:

PLC 5250

requires

a

5150RS remote scanner

32 blocks with 82 ohm terminator 115.2K 5,000 cable-feet

32 blocks with 82 ohm terminator 230.4K 2,500 cable-feet

TABLE CONTINUED ON NEXT PAGE

Chapter

Objectives

Pre-installation

Considerations