User Manual Owner's manual

Table Of Contents

- 1772-6.5.8, Mini-PLC-2/02, -2/16, -2/17 Processor, User Manual

- Important User Information

- Summary of Changes

- Table of Contents

- 1 - Using This Manual

- 2 - Fundamentals of a Programmable Controller

- 3 - Hardware Features

- 4 - Installing Your Programmable Controller

- 5 - Starting Your Processor

- 6 - Maintaining and Troubleshooting Your Processor

- 7 - Memory Organization

- 8 - Scan Theory

- 9 - Relay-Like Instructions

- 10 - Program Control Instructions

- 11 - Timers and Counters

- 12 - Data Manipulation and Compare Instructions

- 13 - Three-Digit Math Instructions

- 14 - EAF Math Instructions

- 15 - EAF Log, Trig, and FIFO Instructions

- 16 - EAF Process Control Instructions

- 17 - Jump Instructions and Subroutines

- 18 - Block Transfer

- 19 - Data Transfer Instructions

- 20 - Bit Shift Registers

- 21 - Sequencers

- 22 - Selectable Timer Interrupts

- 23 - Report Generation

- 24 - Program Editing

- 25 - Programming Techniques

- 26 - Program Troubleshooting

- A - Specifications

- B - Processor Comparison Chart

- C - Number Systems

- D - Glossary

- E - Quick Reference

- Index

- Back Cover

Fundamentals of a

Programmable Controller

Chapter 2

2-9

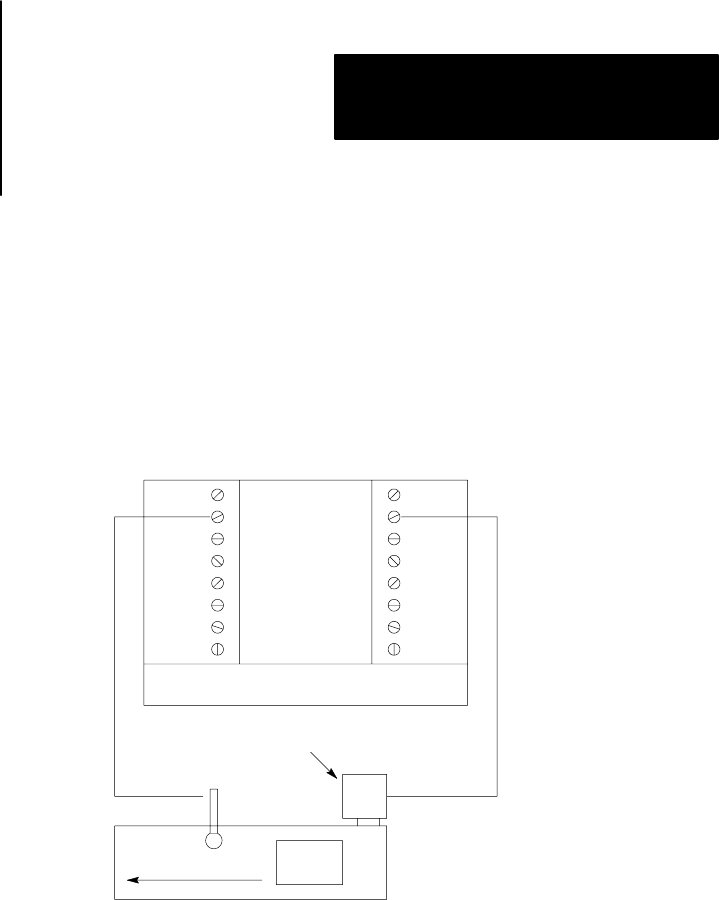

Let’s look at a simple example to see the sequence of events that take place

in controlling a machine with a programmable controller (Figure 2.1).

Suppose you are making a part. The motor driven conveyor carries a unit

to the work area. The limit switch detects wen the part arrives at the work

area. when that happens, we want the conveyor to stop so you can work on

the part.

Figure 2.1

A

Simplified Example of a Machine with a Programmable Controller

Conveyor

Motor

Limit

Switch

Conveyor

Unit

Controller

Input Output

11594

Notice how the limit switch and motor are wired to the programmable

controller. The limit switch, wired to terminal 02, is normally-closed. The

arriving part will open the switch. Therefore, the program statement

controlling the conveyor motor must read: “If there is voltage at input

terminal 02 (limit switch), then energize output terminal 02 (conveyer

motor).” The conveyor motor is wired to output terminal 02.

Important: Figure 2.1 is for demonstration purposes only. We do not

show the associated wiring, a motor starter, or an emergency stop button.

Since the limit switch is wired normally-closed, the conveyor motor runs

until the arriving part opens the switch. At that time, the condition for

energizing the motor is not longer met. Therefore, the motor is

de-energized.

When the condition is met, we say it is true. When the condition is not

met, we say it is false. There may be more than one condition which must

be met before an action is executed. When all the conditions are met, the

action is executed and we say the statement is true. When one or more of

the conditions are false, the action is not executed and we say the statement

is false.

Control Sequence