User Manual Owner's manual

Table Of Contents

- 1772-6.5.8, Mini-PLC-2/02, -2/16, -2/17 Processor, User Manual

- Important User Information

- Summary of Changes

- Table of Contents

- 1 - Using This Manual

- 2 - Fundamentals of a Programmable Controller

- 3 - Hardware Features

- 4 - Installing Your Programmable Controller

- 5 - Starting Your Processor

- 6 - Maintaining and Troubleshooting Your Processor

- 7 - Memory Organization

- 8 - Scan Theory

- 9 - Relay-Like Instructions

- 10 - Program Control Instructions

- 11 - Timers and Counters

- 12 - Data Manipulation and Compare Instructions

- 13 - Three-Digit Math Instructions

- 14 - EAF Math Instructions

- 15 - EAF Log, Trig, and FIFO Instructions

- 16 - EAF Process Control Instructions

- 17 - Jump Instructions and Subroutines

- 18 - Block Transfer

- 19 - Data Transfer Instructions

- 20 - Bit Shift Registers

- 21 - Sequencers

- 22 - Selectable Timer Interrupts

- 23 - Report Generation

- 24 - Program Editing

- 25 - Programming Techniques

- 26 - Program Troubleshooting

- A - Specifications

- B - Processor Comparison Chart

- C - Number Systems

- D - Glossary

- E - Quick Reference

- Index

- Back Cover

Chapter

2

2-1

Fundamentals of a Programmable Controller

In this chapter, you review general fundamentals common to our

programmable controllers. This chapter:

describes what a programmable controller does

describe the functions of a programmable controller

describes the four major sections of a programmable controller

gives an example of a simple program

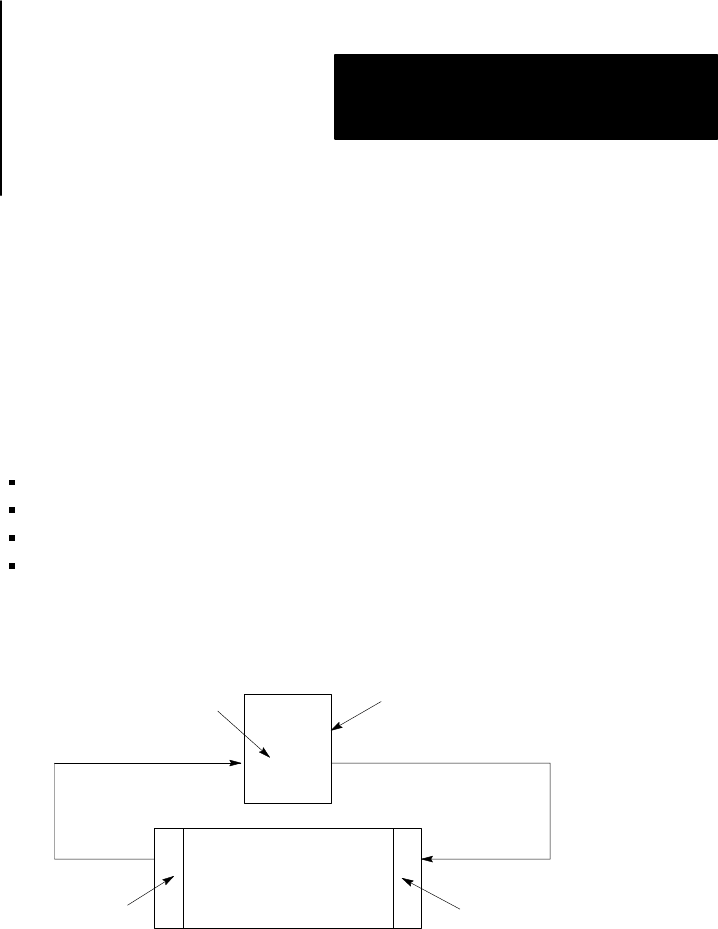

You are probably familiar with the traditional methods of machine control.

Control Panel

Relays

Machine

Sensing

Devices

Output

Devices

11591

Sensing devices located on the machine detect changes in the machine’s

condition. For instance, a part arriving at a work station contacts and

closes a limit switch, the sensing device. As a result, an electrical circuit is

completed and a signal is sent to the control panel.

At the control panel, the electrical signal enters a bank of relays or other

devices, such as solid state modules. Circuits within the control panel open

or close causing additional electrical signals to be sent to output devices at

the machine. For example, a relay energized by the limit switch closed by

the arriving part may complete another circuit energizing the output

device, a clamp, which secures the part at the work station.

Chapter Objectives

Traditional Controls