User Manual

Table Of Contents

- 1771-6.5.88, Plastic Molding Module Reference Manual

- Summary of Changes

- Table of Contents

- Preface

- 1 - Abbreviated Command and Status Blocks

- Chapter Contents

- CLC - Clamp and Eject ERC Values Block

- CPC - Clamp Close Profile Block

- DYC - Dynamic Command Block

- EAC - Ejector Advance Configuration Block

- EPC - Ejector Profile Block

- ERC - Ejector Retract Configuration Block

- FCC - First Clamp Close Configuration Block

- FOC - First Clamp Open Configuration Block

- HDC - Hold Configuration Block

- HPC - Pack/Hold Profile Block

- INC - Injection Configuration Block

- IPC - Injection Profile Block

- JGC - Jog Configuration Block

- LPC - Clamp Low Pressure Close Configuration Block

- MCC - Module Configuration Command Block

- OPC - Clamp Open Profile Block

- OSC - Clamp Open Slow Configuration Block

- PKC - Pack Configuration Block

- PLC - Plastication Configuration Block

- PPC - Plastication Profile Block

- PRC - Pre-decompression Configuration Block

- PSC - Post- decompression Configuration Block

- PTC - Process Trace Configuration Block

- RLC - Inject ERC Values Block

- SCC - Second Clamp Close Configuration Block

- SOC - Second Clamp Open Configuration Block

- TCC - Third Clamp Close Configuration Block

- TOC - Third Clamp Open Configuration Block

- CLS - Clamp and Eject ERC Values Status Block

- CPS - Clamp Close Profiles Status Block

- EPS - Ejector Profile Status Block

- HPS - Pack/Hold Profile Status Block

- IPS - Injection Profile Status Block

- OPS - Clamp Open Profiles Status Block

- PPS - Plastication Profile Status Block

- PTS - Process Trace Status Block

- RLS - Inject ERC Values Status Block

- SYS - System Status Block

- 2 - Command Word/Bit Descriptions

- Alphabetical List of Command Blocks and Block ID Codes

- List of Data Words

- Engineering Units

- Data Blocks Require I/O Configuration

- Data Blocks for System Control

- Data Blocks for Controlling Ram (Screw) Position

- Data Blocks for Controlling Clamp Position

- Data Blocks for Controlling Ejector Position

- Sensors Required

- CLC CLC - Clamp and Eject ERC Values Block

- CPC - Clamp Close Profile Block

- DYC DYC - Dynamic Command Block

- EAC - Ejector Advance Configuration Block

- EPC - Ejector Profile Block

- ERC - Ejector Retract Configuration Block

- FCC - First Clamp Close Configuration Block

- FOC - First Clamp Open Configuration Block

- HDC - Hold Configuration Block

- HPC - Pack/Hold Profile Block

- INC - Injection Configuration Block

- IPC - Injection Profile Block

- JGC - Jog Configuration Block

- LPC - Clamp Low Pressure Close Configuration Block

- MCC - Module Configuration Command Block

- OPC - Clamp Open Profile Block

- OSC - Clamp Open Slow Configuration Block

- PKC - Pack Configuration Block

- PLC Plastication Configuration Command Block (PLC)

- PPC - Plastication Profile Block

- PRC - Pre-decompression Configuration Block

- PSC - Post-decompression Configuration Block

- PTC - Process Trace Configuration Block

- RLC - Inject ERC Values Block

- SCC - Second Clamp Close Configuration Block

- SOC - Second Clamp Open Configuration Block

- TCC - Third Clamp Close Configuration Block

- TOC - Third Clamp Open Configuration Block

- 3 - Word/Bit Descriptions

- List of Status Blocks and Block ID Codes

- List of Data Words

- Data Blocks Require I/O Configuration

- Engineering Units

- Status Block for Reporting System Status

- Status Blocks for Reporting Ram (Screw) Position

- Status Blocks for Reporting Clamp Position

- Status Blocks for Reporting Ejector Position

- CLS - Clamp and Eject ERC Values Status Block

- CPS - Clamp Close Profiles Status Block

- EPS - Ejector Profile Status Block

- HPS - Pack/Hold Profile Status Block

- IPS ú Injection Profile Status Block

- OPS - Clamp Open Profiles Status Block

- PPS - Plastication Profile Status Block

- PTS - Process Trace Status Block

- RLS - Inject ERC Values Status Block

- SYS - System Status Block

- 4 - Programming Error Codes

- 5 - Module Specifications

- 6 - Calibration Instructions

- A - Single transfer for Reporting Ejector Status

- Back cover

1–48 Abbreviated Command and Status Blocks

Publication

1771-6.5.88 – July 1997

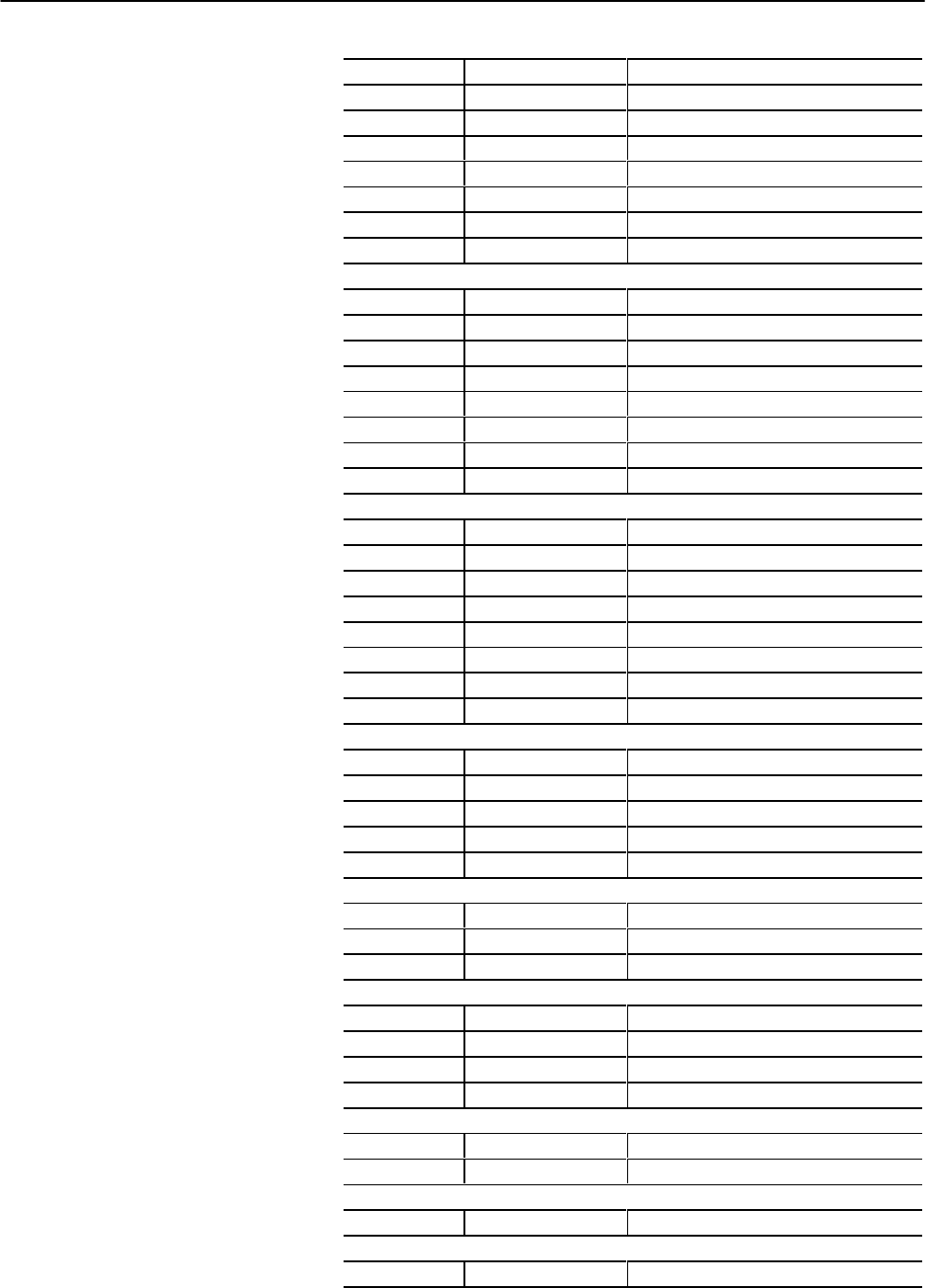

Input Level in Engineering Units

SYS25

N40:177 Input #1

SYS26 N40:178 Input #2

SYS27 N40:179 Input #3

SYS28 N40:180 Input #4

SYS29 N40:181 Input #5

SYS30 N40:182 Input #6

SYS31 N40:183 Input #7

SYS32 N40:184 Input #8

Input Level, Raw Signal Level at A/D Converter

SYS33 N40:185 Input #1

SYS34 N40:186 Input #2

SYS35 N40:187 Input #3

SYS36 N40:188 Input #4

SYS37 N40:189 Input #5

SYS38 N40:190 Input #6

SYS39 N40:191 Input #7

SYS40 N40:192 Input #8

Output Level in Percent

SYS41 N40:193 Output #1

SYS42 N40:194 Output #2

SYS43 N40:195 Output #3

SYS44 N40:196 Output #4

SYS45 N40:197 Output #5

SYS46 N40:198 Output #6

SYS47 N40:199 Output #7

SYS48 N40:200 Output #8

Maximum Pressures of Each Cycle

SYS49 N40:201 Maximum ram (screw) pressure, last cycle

SYS50 N40:202 Maximum clamp pressure, last cycle

SYS51 N40:203 Maximum ejector pressure, last cycle

SYS52 N40:204 Maximum cavity pressure, last cycle

SYS53 N40:205 Open

Process Trace

SYS54 N40:206 Process trace data collection in progress

SYS55 N40:207 Process trace data collection done

SYS56 N40:208 RFU

Accumulated Process Times

SYS57 N40:209 Tonnage

SYS58 N40:210 Cure

SYS59 N40:211 Mold open dwell

SYS60 N40:212 Cycle

Programming Error Codes

SYS61 N40:213 ID of data block with error

SYS62 N40:214 Programming error code

Firmware ID

SYS63 N40:215 QDC Series/Revision

Confirmation of New Status

SYS64 N40:216 Counter accumulated value, each new SYS