User Manual

Table Of Contents

- 1771-6.5.88, Plastic Molding Module Reference Manual

- Summary of Changes

- Table of Contents

- Preface

- 1 - Abbreviated Command and Status Blocks

- Chapter Contents

- CLC - Clamp and Eject ERC Values Block

- CPC - Clamp Close Profile Block

- DYC - Dynamic Command Block

- EAC - Ejector Advance Configuration Block

- EPC - Ejector Profile Block

- ERC - Ejector Retract Configuration Block

- FCC - First Clamp Close Configuration Block

- FOC - First Clamp Open Configuration Block

- HDC - Hold Configuration Block

- HPC - Pack/Hold Profile Block

- INC - Injection Configuration Block

- IPC - Injection Profile Block

- JGC - Jog Configuration Block

- LPC - Clamp Low Pressure Close Configuration Block

- MCC - Module Configuration Command Block

- OPC - Clamp Open Profile Block

- OSC - Clamp Open Slow Configuration Block

- PKC - Pack Configuration Block

- PLC - Plastication Configuration Block

- PPC - Plastication Profile Block

- PRC - Pre-decompression Configuration Block

- PSC - Post- decompression Configuration Block

- PTC - Process Trace Configuration Block

- RLC - Inject ERC Values Block

- SCC - Second Clamp Close Configuration Block

- SOC - Second Clamp Open Configuration Block

- TCC - Third Clamp Close Configuration Block

- TOC - Third Clamp Open Configuration Block

- CLS - Clamp and Eject ERC Values Status Block

- CPS - Clamp Close Profiles Status Block

- EPS - Ejector Profile Status Block

- HPS - Pack/Hold Profile Status Block

- IPS - Injection Profile Status Block

- OPS - Clamp Open Profiles Status Block

- PPS - Plastication Profile Status Block

- PTS - Process Trace Status Block

- RLS - Inject ERC Values Status Block

- SYS - System Status Block

- 2 - Command Word/Bit Descriptions

- Alphabetical List of Command Blocks and Block ID Codes

- List of Data Words

- Engineering Units

- Data Blocks Require I/O Configuration

- Data Blocks for System Control

- Data Blocks for Controlling Ram (Screw) Position

- Data Blocks for Controlling Clamp Position

- Data Blocks for Controlling Ejector Position

- Sensors Required

- CLC CLC - Clamp and Eject ERC Values Block

- CPC - Clamp Close Profile Block

- DYC DYC - Dynamic Command Block

- EAC - Ejector Advance Configuration Block

- EPC - Ejector Profile Block

- ERC - Ejector Retract Configuration Block

- FCC - First Clamp Close Configuration Block

- FOC - First Clamp Open Configuration Block

- HDC - Hold Configuration Block

- HPC - Pack/Hold Profile Block

- INC - Injection Configuration Block

- IPC - Injection Profile Block

- JGC - Jog Configuration Block

- LPC - Clamp Low Pressure Close Configuration Block

- MCC - Module Configuration Command Block

- OPC - Clamp Open Profile Block

- OSC - Clamp Open Slow Configuration Block

- PKC - Pack Configuration Block

- PLC Plastication Configuration Command Block (PLC)

- PPC - Plastication Profile Block

- PRC - Pre-decompression Configuration Block

- PSC - Post-decompression Configuration Block

- PTC - Process Trace Configuration Block

- RLC - Inject ERC Values Block

- SCC - Second Clamp Close Configuration Block

- SOC - Second Clamp Open Configuration Block

- TCC - Third Clamp Close Configuration Block

- TOC - Third Clamp Open Configuration Block

- 3 - Word/Bit Descriptions

- List of Status Blocks and Block ID Codes

- List of Data Words

- Data Blocks Require I/O Configuration

- Engineering Units

- Status Block for Reporting System Status

- Status Blocks for Reporting Ram (Screw) Position

- Status Blocks for Reporting Clamp Position

- Status Blocks for Reporting Ejector Position

- CLS - Clamp and Eject ERC Values Status Block

- CPS - Clamp Close Profiles Status Block

- EPS - Ejector Profile Status Block

- HPS - Pack/Hold Profile Status Block

- IPS ú Injection Profile Status Block

- OPS - Clamp Open Profiles Status Block

- PPS - Plastication Profile Status Block

- PTS - Process Trace Status Block

- RLS - Inject ERC Values Status Block

- SYS - System Status Block

- 4 - Programming Error Codes

- 5 - Module Specifications

- 6 - Calibration Instructions

- A - Single transfer for Reporting Ejector Status

- Back cover

6–8 Calibration Instructions

Publication

1771-6.5.88 – July 1997

After calibrating inputs, calibrate outputs as follows:

• change jumpers as required (with power ON)

• enter command codes in BTW word 2

• enter voltage codes in BTW words 3, 4, 5, and 6

• read verification codes in BTR words 10, 11, 12, and 13

Important: Do not remove module from the I/O chassis or turn off

power. Loss of power voids the procedure and requires

that you repeat the entire calibration procedure starting

with inputs.

1. With the power remaining ON, connect the output wiring arm.

2. To calibrate the –10 to +10V dc output range, follow these steps:

Step Enter Command Code (BTW 2): and Read in BTR:

1 0020H word 4 = 000F

2 8020H word 5 = 000F

3. To verify –10 to +10V range, enter command codes 0100H and 8100H.

Then enter voltage codes:

Step Enter Voltage Code (BTW 3-6): and Read Verification Code (BTR 10-13):

1 000H (for 0 volts) 000H

2 0400H (for +5 volts) 0800H

3 7FFH (for +10 volts) FFFH

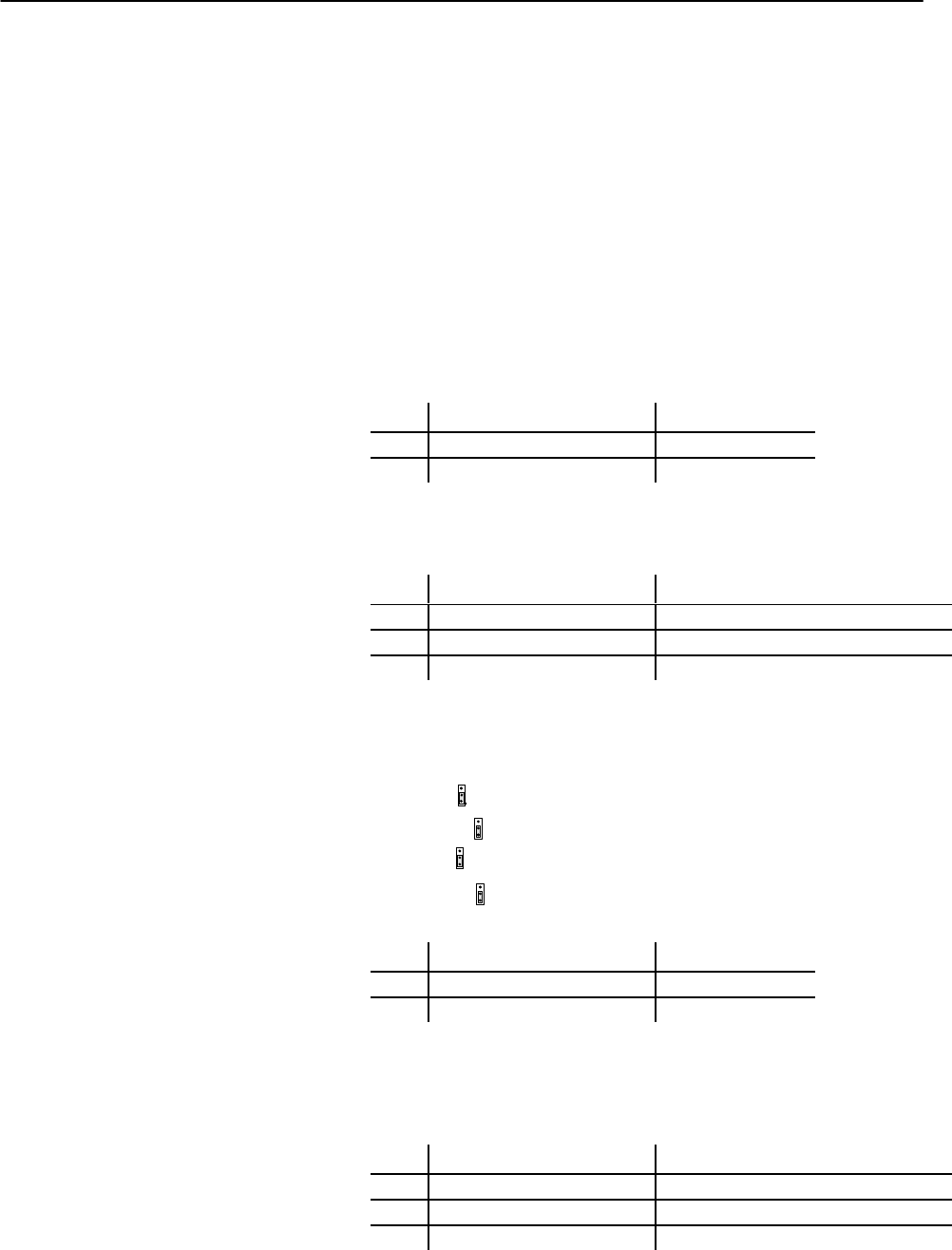

4. To calibrate the 0 to +10V dc range, first change these jumpers with

power ON: E11, E12, E15, E16 to the 0 to +10V dc position (bottom)

E16

E11

E15

E12

Step Enter Command Code (BTW 2): and Read in BTR:

1 0040H word 4 = 00FF

2 8040H word 5 = 00FF

5. To verify 0 to +10V range, enter command codes 0400H and 8400H.

Then enter voltage codes:

Step Enter Voltage Code (BTW 3-6): and Read Verification Code (BTR 10-13):

1 000H (for 0 volts) 000H

2 0800H (for +5 volts) 0800H

3 FFFH (for +10 volts) FFFH

Calibration Procedure

for Outputs