User Manual

Table Of Contents

- 1771-6.5.88, Plastic Molding Module Reference Manual

- Summary of Changes

- Table of Contents

- Preface

- 1 - Abbreviated Command and Status Blocks

- Chapter Contents

- CLC - Clamp and Eject ERC Values Block

- CPC - Clamp Close Profile Block

- DYC - Dynamic Command Block

- EAC - Ejector Advance Configuration Block

- EPC - Ejector Profile Block

- ERC - Ejector Retract Configuration Block

- FCC - First Clamp Close Configuration Block

- FOC - First Clamp Open Configuration Block

- HDC - Hold Configuration Block

- HPC - Pack/Hold Profile Block

- INC - Injection Configuration Block

- IPC - Injection Profile Block

- JGC - Jog Configuration Block

- LPC - Clamp Low Pressure Close Configuration Block

- MCC - Module Configuration Command Block

- OPC - Clamp Open Profile Block

- OSC - Clamp Open Slow Configuration Block

- PKC - Pack Configuration Block

- PLC - Plastication Configuration Block

- PPC - Plastication Profile Block

- PRC - Pre-decompression Configuration Block

- PSC - Post- decompression Configuration Block

- PTC - Process Trace Configuration Block

- RLC - Inject ERC Values Block

- SCC - Second Clamp Close Configuration Block

- SOC - Second Clamp Open Configuration Block

- TCC - Third Clamp Close Configuration Block

- TOC - Third Clamp Open Configuration Block

- CLS - Clamp and Eject ERC Values Status Block

- CPS - Clamp Close Profiles Status Block

- EPS - Ejector Profile Status Block

- HPS - Pack/Hold Profile Status Block

- IPS - Injection Profile Status Block

- OPS - Clamp Open Profiles Status Block

- PPS - Plastication Profile Status Block

- PTS - Process Trace Status Block

- RLS - Inject ERC Values Status Block

- SYS - System Status Block

- 2 - Command Word/Bit Descriptions

- Alphabetical List of Command Blocks and Block ID Codes

- List of Data Words

- Engineering Units

- Data Blocks Require I/O Configuration

- Data Blocks for System Control

- Data Blocks for Controlling Ram (Screw) Position

- Data Blocks for Controlling Clamp Position

- Data Blocks for Controlling Ejector Position

- Sensors Required

- CLC CLC - Clamp and Eject ERC Values Block

- CPC - Clamp Close Profile Block

- DYC DYC - Dynamic Command Block

- EAC - Ejector Advance Configuration Block

- EPC - Ejector Profile Block

- ERC - Ejector Retract Configuration Block

- FCC - First Clamp Close Configuration Block

- FOC - First Clamp Open Configuration Block

- HDC - Hold Configuration Block

- HPC - Pack/Hold Profile Block

- INC - Injection Configuration Block

- IPC - Injection Profile Block

- JGC - Jog Configuration Block

- LPC - Clamp Low Pressure Close Configuration Block

- MCC - Module Configuration Command Block

- OPC - Clamp Open Profile Block

- OSC - Clamp Open Slow Configuration Block

- PKC - Pack Configuration Block

- PLC Plastication Configuration Command Block (PLC)

- PPC - Plastication Profile Block

- PRC - Pre-decompression Configuration Block

- PSC - Post-decompression Configuration Block

- PTC - Process Trace Configuration Block

- RLC - Inject ERC Values Block

- SCC - Second Clamp Close Configuration Block

- SOC - Second Clamp Open Configuration Block

- TCC - Third Clamp Close Configuration Block

- TOC - Third Clamp Open Configuration Block

- 3 - Word/Bit Descriptions

- List of Status Blocks and Block ID Codes

- List of Data Words

- Data Blocks Require I/O Configuration

- Engineering Units

- Status Block for Reporting System Status

- Status Blocks for Reporting Ram (Screw) Position

- Status Blocks for Reporting Clamp Position

- Status Blocks for Reporting Ejector Position

- CLS - Clamp and Eject ERC Values Status Block

- CPS - Clamp Close Profiles Status Block

- EPS - Ejector Profile Status Block

- HPS - Pack/Hold Profile Status Block

- IPS ú Injection Profile Status Block

- OPS - Clamp Open Profiles Status Block

- PPS - Plastication Profile Status Block

- PTS - Process Trace Status Block

- RLS - Inject ERC Values Status Block

- SYS - System Status Block

- 4 - Programming Error Codes

- 5 - Module Specifications

- 6 - Calibration Instructions

- A - Single transfer for Reporting Ejector Status

- Back cover

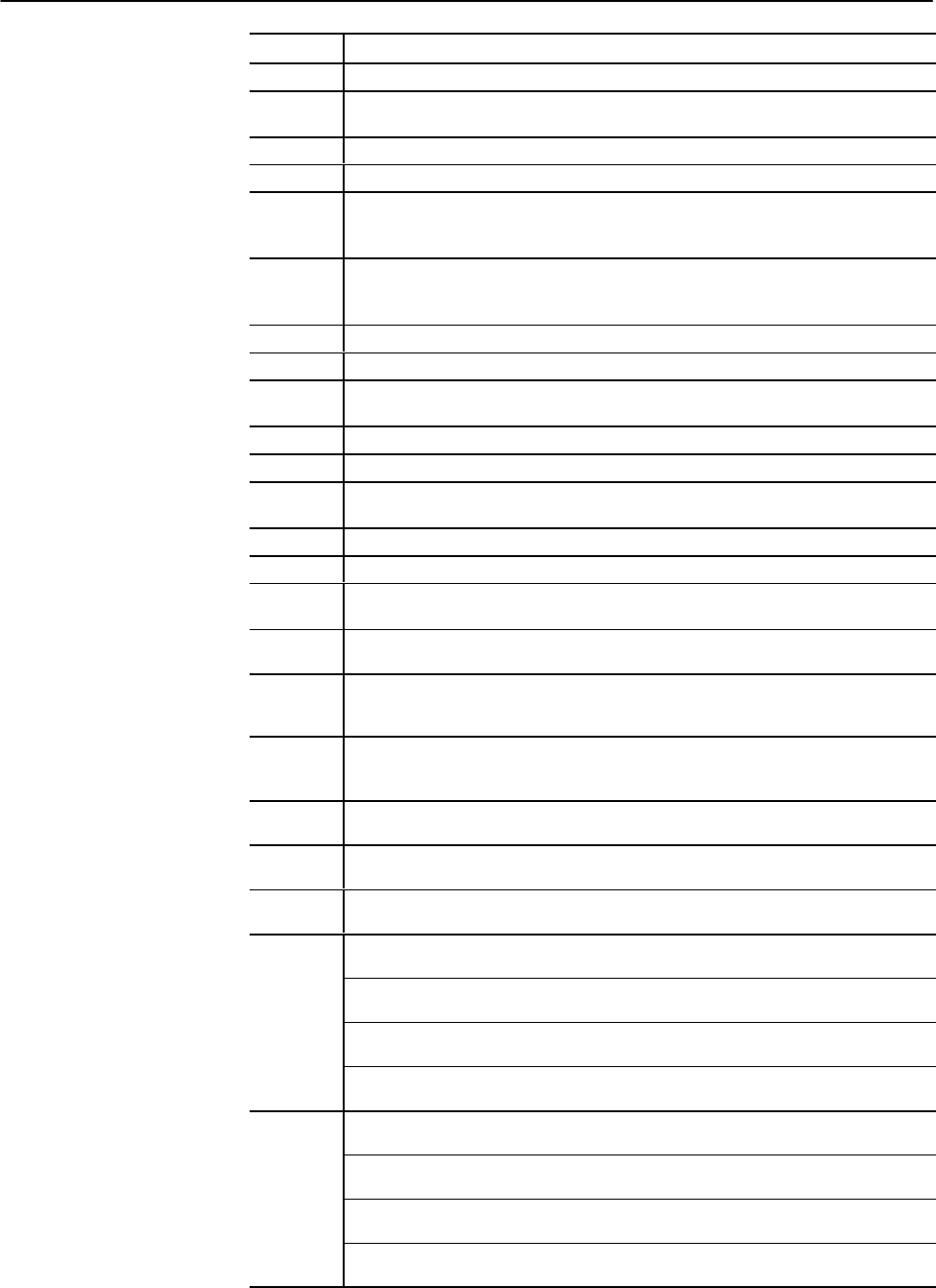

4–5Programming Error Codes

Publication

1771-6.5.88 – July 1997

Error Code

Description

ID = 1

0432

MCC32 is out of range. Valid range is MCC31 < MCC32

≤

09999

0435 MCC35 is out of range.

If non-zero, MCC35 must be within MCC31 < MCC35

≤

MCC32

0437

MCC37 is out of range. Valid range is 00000

≤

MCC37 < MCC38

0438

MCC38 is out of range. Valid range is MCC37 < MCC38

≤

09999

0441 Your non-zero entry for MCC41 is out of range.

If MCC42 is non-zero, MCC41 must be within MCC37

≤

MCC41 < MCC42

If MCC42 is zero, MCC41 must be within MCC37

≤

MCC41 < MCC38

0442 Your non-zero entry for MCC42 is out of range.

If MCC41 is non-zero, MCC42 must be within MCC41 < MCC42

≤

MCC38

If MCC41 is zero, MCC42 must be within MCC37 < MCC42

≤

MCC38

0445

MCC45 is out of range. Valid range is 00000

≤

MCC45 < MCC46

0446

MCC46 is out of range. Valid range is MCC45 < MCC46

≤

09999

0449 MCC49 is out of range.

If non-zero, MCC49 must be within MCC45 < MCC49

≤

MCC46

0451

MCC51 is out of range. Valid range is 00000

≤

MCC51 < MCC52

0452

MCC52 is out of range. Valid range is MCC51 < MCC52

≤

09999

0455 MCC55 is out of range.

If non-zero, MCC55 must be within MCC51 < MCC55

≤

MCC52

0457

MCC57 is out of range. Valid range is 00000

≤

MCC57 < MCC58

0458

MCC58 is out of range. Valid range is MCC57 < MCC58

≤

20000

0461 MCC61 is out of range.

If non-zero, MCC61 must be within MCC57 < MCC61

≤

MCC58

0502 You configured the module for 4x4 I/O by MCC02-B03 = 1.

Therefore, MCC02-B04 = 1 and MCC02-B05 = 1 is illegal.

0503 You configured the module for 4x4 I/O by MCC02-B03 = 1.

Therefore, your bit pattern in the upper byte of MCC03 must be 11111111 to indicate that

inputs #5 through #8 are “unconnected”.

0504 You configured the module for 4x4 I/O by MCC02-B03 = 1.

Therefore, your bit pattern in the upper byte of MCC04 must be 11111111 to indicate that

outputs #5 through #8 are “unconnected”.

0507 Your settings for MCC02-B03, B04, and B05 indicate that module input #1 is reserved for a

ram (screw) position transducer. Therefore MCC03-B00 and B01 cannot both = 1.

0511 Your settings for MCC02-B03, B04, and B05 indicate that module input #3 is reserved for a

clamp position transducer. Therefore MCC03-B00 and B01 cannot both = 1.

0602 You configured the module for 8x8 I/O by MCC02-B03 = 0.

This configuration is not supported by your series/revision of firmware.

0915 MCC15 is too large.

if: then:

MCC13 and MCC14 MCC15 must be within MCC13 + MCC15 < MCC14 – MCC15

are both non-zero

MCC13 is zero and MCC15 must be within MCC09 + MCC15 < MCC14 – MCC15

MCC14 is non-zero

MCC13 is non-zero MCC15 must be within MCC13 + MCC15 < MCC10 – MCC15

and MCC14 is zero

0929 MCC29 is too large.

if: then:

MCC27 and MCC28 MCC29 must be within MCC27 + MCC29 < MCC28 – MCC29

are both non-zero

MCC27 is zero and MCC29 must be within MCC23 + MCC29 < MCC28 – MCC29

MCC28 is non-zero

MCC27 is non-zero MCC29 must be within MCC27 + MCC29 < MCC24 – MCC29

and MCC28 is zero