User Manual

Table Of Contents

- 1771-6.5.88, Plastic Molding Module Reference Manual

- Summary of Changes

- Table of Contents

- Preface

- 1 - Abbreviated Command and Status Blocks

- Chapter Contents

- CLC - Clamp and Eject ERC Values Block

- CPC - Clamp Close Profile Block

- DYC - Dynamic Command Block

- EAC - Ejector Advance Configuration Block

- EPC - Ejector Profile Block

- ERC - Ejector Retract Configuration Block

- FCC - First Clamp Close Configuration Block

- FOC - First Clamp Open Configuration Block

- HDC - Hold Configuration Block

- HPC - Pack/Hold Profile Block

- INC - Injection Configuration Block

- IPC - Injection Profile Block

- JGC - Jog Configuration Block

- LPC - Clamp Low Pressure Close Configuration Block

- MCC - Module Configuration Command Block

- OPC - Clamp Open Profile Block

- OSC - Clamp Open Slow Configuration Block

- PKC - Pack Configuration Block

- PLC - Plastication Configuration Block

- PPC - Plastication Profile Block

- PRC - Pre-decompression Configuration Block

- PSC - Post- decompression Configuration Block

- PTC - Process Trace Configuration Block

- RLC - Inject ERC Values Block

- SCC - Second Clamp Close Configuration Block

- SOC - Second Clamp Open Configuration Block

- TCC - Third Clamp Close Configuration Block

- TOC - Third Clamp Open Configuration Block

- CLS - Clamp and Eject ERC Values Status Block

- CPS - Clamp Close Profiles Status Block

- EPS - Ejector Profile Status Block

- HPS - Pack/Hold Profile Status Block

- IPS - Injection Profile Status Block

- OPS - Clamp Open Profiles Status Block

- PPS - Plastication Profile Status Block

- PTS - Process Trace Status Block

- RLS - Inject ERC Values Status Block

- SYS - System Status Block

- 2 - Command Word/Bit Descriptions

- Alphabetical List of Command Blocks and Block ID Codes

- List of Data Words

- Engineering Units

- Data Blocks Require I/O Configuration

- Data Blocks for System Control

- Data Blocks for Controlling Ram (Screw) Position

- Data Blocks for Controlling Clamp Position

- Data Blocks for Controlling Ejector Position

- Sensors Required

- CLC CLC - Clamp and Eject ERC Values Block

- CPC - Clamp Close Profile Block

- DYC DYC - Dynamic Command Block

- EAC - Ejector Advance Configuration Block

- EPC - Ejector Profile Block

- ERC - Ejector Retract Configuration Block

- FCC - First Clamp Close Configuration Block

- FOC - First Clamp Open Configuration Block

- HDC - Hold Configuration Block

- HPC - Pack/Hold Profile Block

- INC - Injection Configuration Block

- IPC - Injection Profile Block

- JGC - Jog Configuration Block

- LPC - Clamp Low Pressure Close Configuration Block

- MCC - Module Configuration Command Block

- OPC - Clamp Open Profile Block

- OSC - Clamp Open Slow Configuration Block

- PKC - Pack Configuration Block

- PLC Plastication Configuration Command Block (PLC)

- PPC - Plastication Profile Block

- PRC - Pre-decompression Configuration Block

- PSC - Post-decompression Configuration Block

- PTC - Process Trace Configuration Block

- RLC - Inject ERC Values Block

- SCC - Second Clamp Close Configuration Block

- SOC - Second Clamp Open Configuration Block

- TCC - Third Clamp Close Configuration Block

- TOC - Third Clamp Open Configuration Block

- 3 - Word/Bit Descriptions

- List of Status Blocks and Block ID Codes

- List of Data Words

- Data Blocks Require I/O Configuration

- Engineering Units

- Status Block for Reporting System Status

- Status Blocks for Reporting Ram (Screw) Position

- Status Blocks for Reporting Clamp Position

- Status Blocks for Reporting Ejector Position

- CLS - Clamp and Eject ERC Values Status Block

- CPS - Clamp Close Profiles Status Block

- EPS - Ejector Profile Status Block

- HPS - Pack/Hold Profile Status Block

- IPS ú Injection Profile Status Block

- OPS - Clamp Open Profiles Status Block

- PPS - Plastication Profile Status Block

- PTS - Process Trace Status Block

- RLS - Inject ERC Values Status Block

- SYS - System Status Block

- 4 - Programming Error Codes

- 5 - Module Specifications

- 6 - Calibration Instructions

- A - Single transfer for Reporting Ejector Status

- Back cover

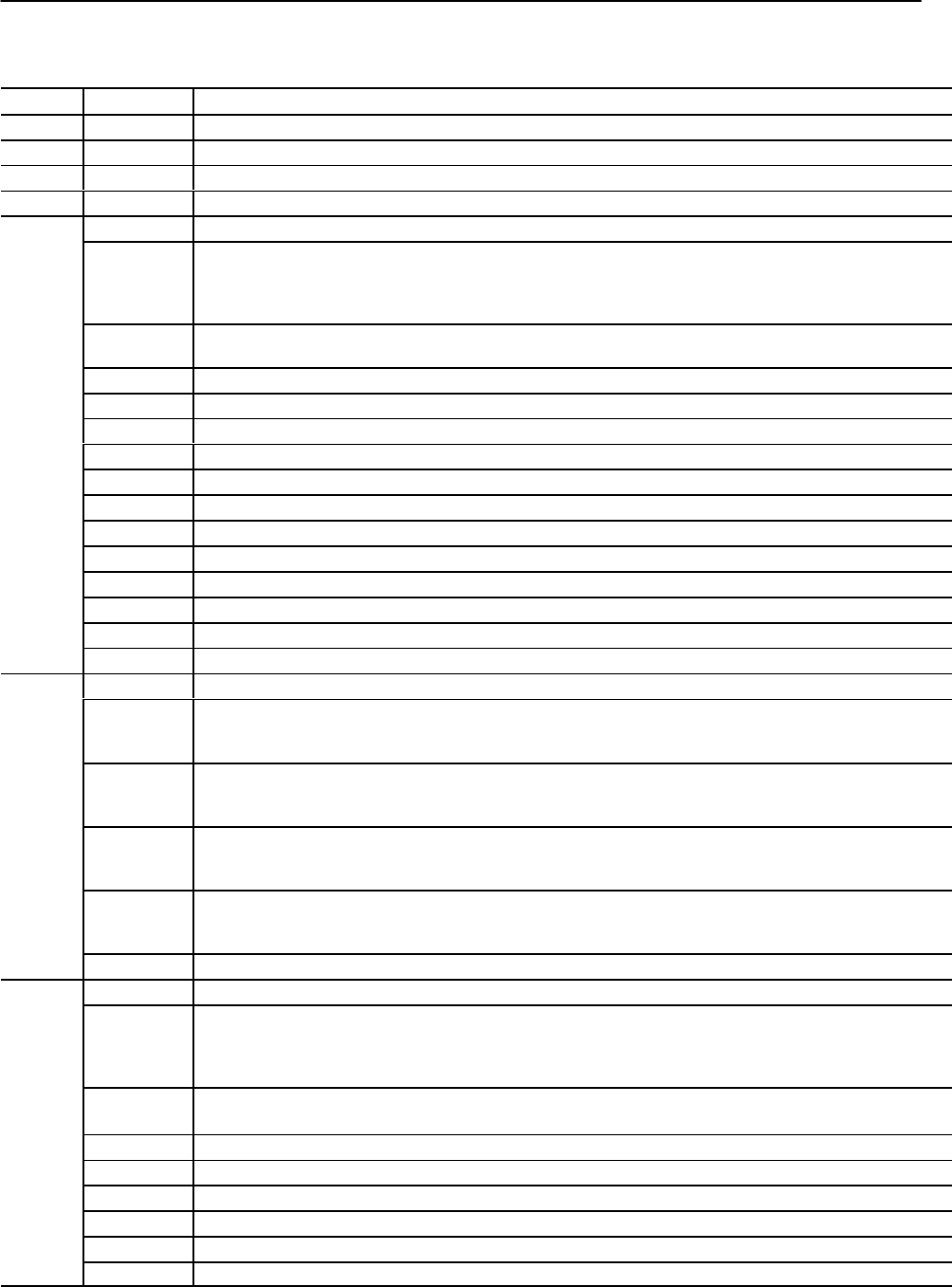

3–14 Status Word/Bit Descriptions

Publication

1771-6.5.88 – July 1997

Notes: 1. For [ ] engineering units, see page 3.

2. When using the Inject/Clamp/Eject mode, all pressure readings are system pressure at input 2, except where noted.

Bit-mapped Status Words

Word Bit Description

IPS01 Block ID = 00000011 (Low byte). High byte identical to SYS01

IPS02 See SYS02

IPS03 See SYS03

IPS04 See SYS04

IPS05 Pressure Limit Alarms

The module latches bits individually when executing a pressure-limited Vel/Pos Injection Profile and monitors a real-

time ram (screw) pressure equal to or greater than IPC57 during the subject profile segment. The module unlatches

each bit when it completes the segment without monitoring a real-time ram (screw) pressure equal to or greater than

IPC57.

This bit is

latched ON:

at pressure limit for

this LimVel/Pos segment:

B00 Segment 1

B01 Segment 2

B02 Segment 3

B03 Segment 4

B04 Segment 5

B05 Segment 6

B06 Segment 7

B07 Segment 8

B08 Segment 9

B09 Segment 10

B10 Segment 11

B11-B15 Open

IPS06 Injection Transition Status

B00 = 0 Normal

= 1 Injection Transition on Time

The module sets this bit when the Transition Time Setpoint (IPC60) triggered completion of last Injection Profile.

B01 = 0 Normal

= 1 Injection Transition on Ram (Screw) Position

Module sets this bit when Transition Ram (Screw) Position Setpoint (IPC61) triggered completion of last Injection Profile

B02 = 0 Normal

= 1 Injection Transition on Ram (Screw) Pressure

Module sets bit when Transition Ram (Screw) Pressure Setpoint (IPC62) triggered completion of last Injection Profile.

B03 = 0 Normal

= 1 Injection Transition on Cavity Pressure

Module sets this bit when the Transition Cavity Pressure Setpoint (IPC63) triggered completion of last Injection Profile.

B04-B15 Open

IPS07 CV High Limit Alarms

The module latches each bit when executing the subject profile segment in closed loop, and drives its algorithm CV to

maximum (100%) in an attempt to control the profile setpoint.

The module unlatches each bit when it completes execution of the subject profile segment in open loop, or in closed

loop without driving its algorithm CV to maximum (100%).

When this bit

is latched ON:

algorithm CV

is maximum during:

B00 Segment 1

B01 Segment 2

B02 Segment 3

B03 Segment 4

B04 Segment 5

B05 Segment 6

IPS – Injection Profile

Status Block