User Manual

Table Of Contents

- 1771-6.5.88, Plastic Molding Module Reference Manual

- Summary of Changes

- Table of Contents

- Preface

- 1 - Abbreviated Command and Status Blocks

- Chapter Contents

- CLC - Clamp and Eject ERC Values Block

- CPC - Clamp Close Profile Block

- DYC - Dynamic Command Block

- EAC - Ejector Advance Configuration Block

- EPC - Ejector Profile Block

- ERC - Ejector Retract Configuration Block

- FCC - First Clamp Close Configuration Block

- FOC - First Clamp Open Configuration Block

- HDC - Hold Configuration Block

- HPC - Pack/Hold Profile Block

- INC - Injection Configuration Block

- IPC - Injection Profile Block

- JGC - Jog Configuration Block

- LPC - Clamp Low Pressure Close Configuration Block

- MCC - Module Configuration Command Block

- OPC - Clamp Open Profile Block

- OSC - Clamp Open Slow Configuration Block

- PKC - Pack Configuration Block

- PLC - Plastication Configuration Block

- PPC - Plastication Profile Block

- PRC - Pre-decompression Configuration Block

- PSC - Post- decompression Configuration Block

- PTC - Process Trace Configuration Block

- RLC - Inject ERC Values Block

- SCC - Second Clamp Close Configuration Block

- SOC - Second Clamp Open Configuration Block

- TCC - Third Clamp Close Configuration Block

- TOC - Third Clamp Open Configuration Block

- CLS - Clamp and Eject ERC Values Status Block

- CPS - Clamp Close Profiles Status Block

- EPS - Ejector Profile Status Block

- HPS - Pack/Hold Profile Status Block

- IPS - Injection Profile Status Block

- OPS - Clamp Open Profiles Status Block

- PPS - Plastication Profile Status Block

- PTS - Process Trace Status Block

- RLS - Inject ERC Values Status Block

- SYS - System Status Block

- 2 - Command Word/Bit Descriptions

- Alphabetical List of Command Blocks and Block ID Codes

- List of Data Words

- Engineering Units

- Data Blocks Require I/O Configuration

- Data Blocks for System Control

- Data Blocks for Controlling Ram (Screw) Position

- Data Blocks for Controlling Clamp Position

- Data Blocks for Controlling Ejector Position

- Sensors Required

- CLC CLC - Clamp and Eject ERC Values Block

- CPC - Clamp Close Profile Block

- DYC DYC - Dynamic Command Block

- EAC - Ejector Advance Configuration Block

- EPC - Ejector Profile Block

- ERC - Ejector Retract Configuration Block

- FCC - First Clamp Close Configuration Block

- FOC - First Clamp Open Configuration Block

- HDC - Hold Configuration Block

- HPC - Pack/Hold Profile Block

- INC - Injection Configuration Block

- IPC - Injection Profile Block

- JGC - Jog Configuration Block

- LPC - Clamp Low Pressure Close Configuration Block

- MCC - Module Configuration Command Block

- OPC - Clamp Open Profile Block

- OSC - Clamp Open Slow Configuration Block

- PKC - Pack Configuration Block

- PLC Plastication Configuration Command Block (PLC)

- PPC - Plastication Profile Block

- PRC - Pre-decompression Configuration Block

- PSC - Post-decompression Configuration Block

- PTC - Process Trace Configuration Block

- RLC - Inject ERC Values Block

- SCC - Second Clamp Close Configuration Block

- SOC - Second Clamp Open Configuration Block

- TCC - Third Clamp Close Configuration Block

- TOC - Third Clamp Open Configuration Block

- 3 - Word/Bit Descriptions

- List of Status Blocks and Block ID Codes

- List of Data Words

- Data Blocks Require I/O Configuration

- Engineering Units

- Status Block for Reporting System Status

- Status Blocks for Reporting Ram (Screw) Position

- Status Blocks for Reporting Clamp Position

- Status Blocks for Reporting Ejector Position

- CLS - Clamp and Eject ERC Values Status Block

- CPS - Clamp Close Profiles Status Block

- EPS - Ejector Profile Status Block

- HPS - Pack/Hold Profile Status Block

- IPS ú Injection Profile Status Block

- OPS - Clamp Open Profiles Status Block

- PPS - Plastication Profile Status Block

- PTS - Process Trace Status Block

- RLS - Inject ERC Values Status Block

- SYS - System Status Block

- 4 - Programming Error Codes

- 5 - Module Specifications

- 6 - Calibration Instructions

- A - Single transfer for Reporting Ejector Status

- Back cover

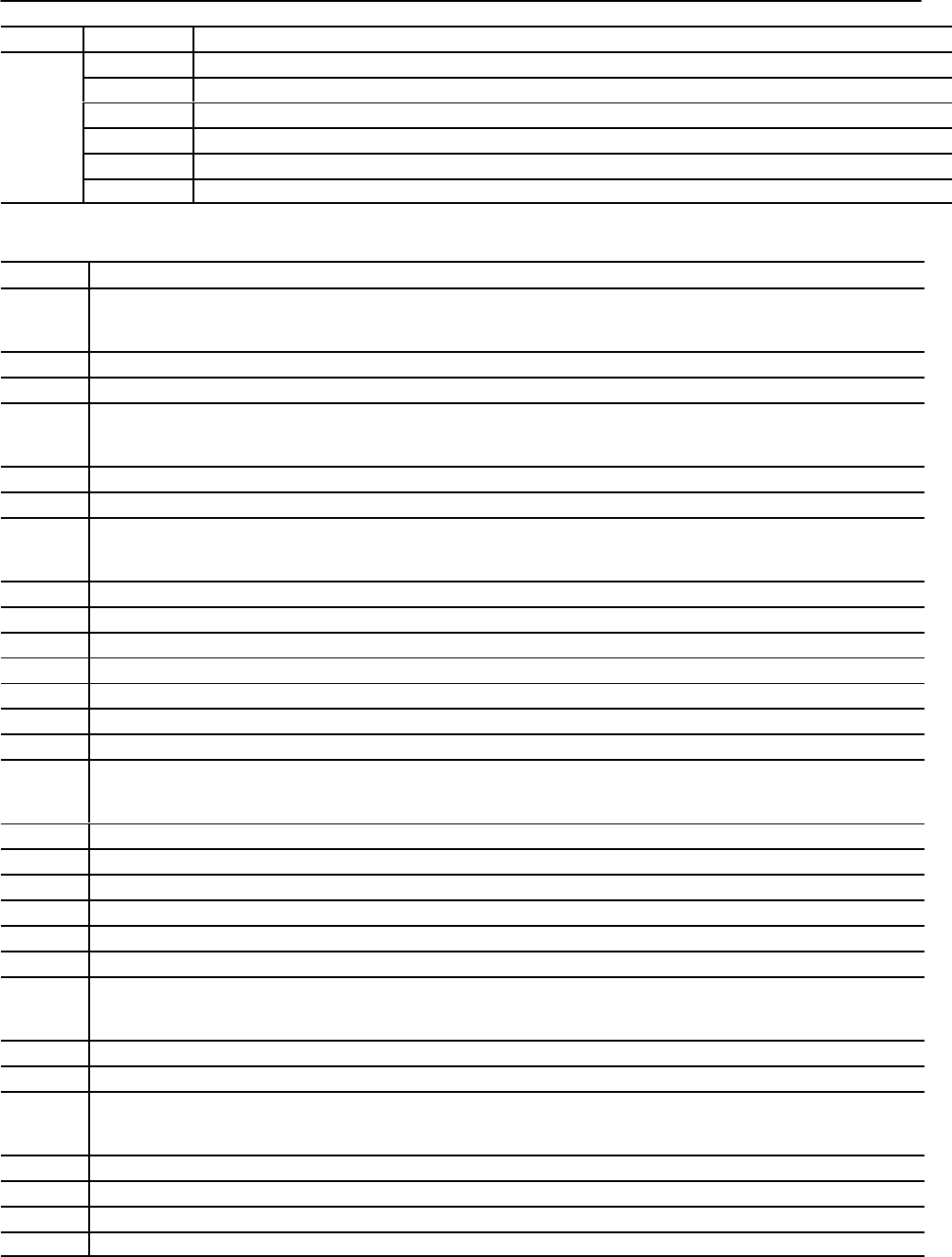

3–10 Status Word/Bit Descriptions

Publication

1771-6.5.88 – July 1997

Notes: 1. For [ ] engineering units, see page 3.

2. When using the Inject/Clamp/Eject mode, all pressure readings are system pressure at input 2, except where noted.

Word DescriptionBit

B06 Tip Advance Segment

B07 Open

B08 Full Retract Segment 1

B09 Full Retract Segment 2

B10 Full Retract Segment 3

B11-B15 Open

Ejector Profile Actuals

Word Description

EPS09 Actual Full Advance Segment 1 Velocity [09] or [10] Average ejector velocity during last Full Advance Segment 1.

If EPC03-B14 is RESET, the module reports this average in percent velocity.

If EPC03-B14 is SET, it reports it in in.(mm)/s.

EPS10 Actual Full Advance Segment 1 Pressure [03] Average ejector pressure during last Full Advance Segment 1.

EPS11 Actual Full Advance Segment 1 Execution Time [21] Time required for last Full Advance Segment 1.

EPS12 Actual Full Advance Segment 2 Velocity [09] or [10] Average ejector velocity during last Full Advance Segment 2.

If EPC03-B14 is RESET, the module reports this average in percent velocity.

If EPC03-B14 is SET, it reports it in in.(mm)/s.

EPS13 Actual Full Advance Segment 2 Pressure [03] Average ejector pressure during last Full Advance Segment 2.

EPS14 Actual Full Advance Segment 2 Execution Time [21] Time required for last Full Advance Segment 2.

EPS15 Actual Full Advance Segment 3 Velocity [09] or [10] Average ejector velocity during last Full Advance Segment 3.

If EPC03-B14 is RESET, the module reports this average in percent velocity.

If EPC03-B14 is SET, it reports it in in.(mm)/s.

EPS16 Actual Full Advance Segment 3 Pressure [03] Average ejector pressure during last Full Advance Segment 3.

EPS17 Actual Full Advance Segment 3 Execution Time [21] Time required for last Full Advance Segment 3.

EPS18 - 20 Reserved

EPS21 Actual Tip Retract Segment Velocity [09] or [10] Average ejector velocity during last Tip Retract Segment.

EPS22 Actual Tip Retract Segment Pressure [03] Average ejector pressure during last Tip Retract Segment.

EPS23 Actual Tip Retract Segment Execution Time [21] Time required for last Tip Retract Segment.

EPS24 - 26 Reserved

EPS27 Actual Tip Advance Segment Velocity [09] or [10] Average ejector velocity during last Tip Advance Segment.

If EPC03-B14 is RESET, the module reports this average in percent velocity.

If EPC03-B14 is SET, it reports it in in.(mm)/s.

EPS28 Actual Tip Advance Segment Pressure [03] Average ejector pressure during last Tip Advance Segment.

EPS29 Actual Tip Advance Segment Execution Time [21] Time required for last Tip Advance Segment.

EPS30 - 32 Reserved

EPS33 Actual Full Retract Segment 1 Velocity [09] or [10] Average ejector velocity during last Full Retract Segment 1.

EPS34 Actual Full Retract Segment 1 Pressure [03] Average ejector pressure during last Full Retract Segment 1.

EPS35 Actual Full Retract Segment 1 Execution Time [21] Time required for last Full Retract Segment 1.

EPS36 Actual Full Retract Segment 2 Velocity [09] or [10] Average ejector velocity during last Full Retract Segment 2.

If EPC03-B14 is RESET, the module reports this average in percent velocity.

If EPC03-B14 is SET, it reports it in in.(mm)/s.

EPS37 Actual Full Retract Segment 2 Pressure [03] Average ejector pressure during last Full Retract Segment 2.

EPS38 Actual Full Retract Segment 2 Execution Time [21] Time required for last Full Retract Segment 2.

EPS39 Actual Full Retract Segment 3 Velocity [09] or [10] Average ejector velocity during last Full Retract Segment 3.

If EPC03-B14 is RESET, the module reports this average in percent velocity.

If EPC03-B14 is SET, it reports it in in.(mm)/s.

EPS40 Actual Full Retract Segment 3 Pressure [03] Average ejector pressure during last Full Retract Segment 3.

EPS41 Actual Full Retract Segment 3 Execution Time [21] Time required for last Full Retract Segment 3.

EPS42 - 44 Reserved

EPS45 - 52 Open