User Manual

Table Of Contents

- 1771-6.5.88, Plastic Molding Module Reference Manual

- Summary of Changes

- Table of Contents

- Preface

- 1 - Abbreviated Command and Status Blocks

- Chapter Contents

- CLC - Clamp and Eject ERC Values Block

- CPC - Clamp Close Profile Block

- DYC - Dynamic Command Block

- EAC - Ejector Advance Configuration Block

- EPC - Ejector Profile Block

- ERC - Ejector Retract Configuration Block

- FCC - First Clamp Close Configuration Block

- FOC - First Clamp Open Configuration Block

- HDC - Hold Configuration Block

- HPC - Pack/Hold Profile Block

- INC - Injection Configuration Block

- IPC - Injection Profile Block

- JGC - Jog Configuration Block

- LPC - Clamp Low Pressure Close Configuration Block

- MCC - Module Configuration Command Block

- OPC - Clamp Open Profile Block

- OSC - Clamp Open Slow Configuration Block

- PKC - Pack Configuration Block

- PLC - Plastication Configuration Block

- PPC - Plastication Profile Block

- PRC - Pre-decompression Configuration Block

- PSC - Post- decompression Configuration Block

- PTC - Process Trace Configuration Block

- RLC - Inject ERC Values Block

- SCC - Second Clamp Close Configuration Block

- SOC - Second Clamp Open Configuration Block

- TCC - Third Clamp Close Configuration Block

- TOC - Third Clamp Open Configuration Block

- CLS - Clamp and Eject ERC Values Status Block

- CPS - Clamp Close Profiles Status Block

- EPS - Ejector Profile Status Block

- HPS - Pack/Hold Profile Status Block

- IPS - Injection Profile Status Block

- OPS - Clamp Open Profiles Status Block

- PPS - Plastication Profile Status Block

- PTS - Process Trace Status Block

- RLS - Inject ERC Values Status Block

- SYS - System Status Block

- 2 - Command Word/Bit Descriptions

- Alphabetical List of Command Blocks and Block ID Codes

- List of Data Words

- Engineering Units

- Data Blocks Require I/O Configuration

- Data Blocks for System Control

- Data Blocks for Controlling Ram (Screw) Position

- Data Blocks for Controlling Clamp Position

- Data Blocks for Controlling Ejector Position

- Sensors Required

- CLC CLC - Clamp and Eject ERC Values Block

- CPC - Clamp Close Profile Block

- DYC DYC - Dynamic Command Block

- EAC - Ejector Advance Configuration Block

- EPC - Ejector Profile Block

- ERC - Ejector Retract Configuration Block

- FCC - First Clamp Close Configuration Block

- FOC - First Clamp Open Configuration Block

- HDC - Hold Configuration Block

- HPC - Pack/Hold Profile Block

- INC - Injection Configuration Block

- IPC - Injection Profile Block

- JGC - Jog Configuration Block

- LPC - Clamp Low Pressure Close Configuration Block

- MCC - Module Configuration Command Block

- OPC - Clamp Open Profile Block

- OSC - Clamp Open Slow Configuration Block

- PKC - Pack Configuration Block

- PLC Plastication Configuration Command Block (PLC)

- PPC - Plastication Profile Block

- PRC - Pre-decompression Configuration Block

- PSC - Post-decompression Configuration Block

- PTC - Process Trace Configuration Block

- RLC - Inject ERC Values Block

- SCC - Second Clamp Close Configuration Block

- SOC - Second Clamp Open Configuration Block

- TCC - Third Clamp Close Configuration Block

- TOC - Third Clamp Open Configuration Block

- 3 - Word/Bit Descriptions

- List of Status Blocks and Block ID Codes

- List of Data Words

- Data Blocks Require I/O Configuration

- Engineering Units

- Status Block for Reporting System Status

- Status Blocks for Reporting Ram (Screw) Position

- Status Blocks for Reporting Clamp Position

- Status Blocks for Reporting Ejector Position

- CLS - Clamp and Eject ERC Values Status Block

- CPS - Clamp Close Profiles Status Block

- EPS - Ejector Profile Status Block

- HPS - Pack/Hold Profile Status Block

- IPS ú Injection Profile Status Block

- OPS - Clamp Open Profiles Status Block

- PPS - Plastication Profile Status Block

- PTS - Process Trace Status Block

- RLS - Inject ERC Values Status Block

- SYS - System Status Block

- 4 - Programming Error Codes

- 5 - Module Specifications

- 6 - Calibration Instructions

- A - Single transfer for Reporting Ejector Status

- Back cover

2–103Command Word/Bit Descriptions

Publication

1771-6.5.88 – July 1997

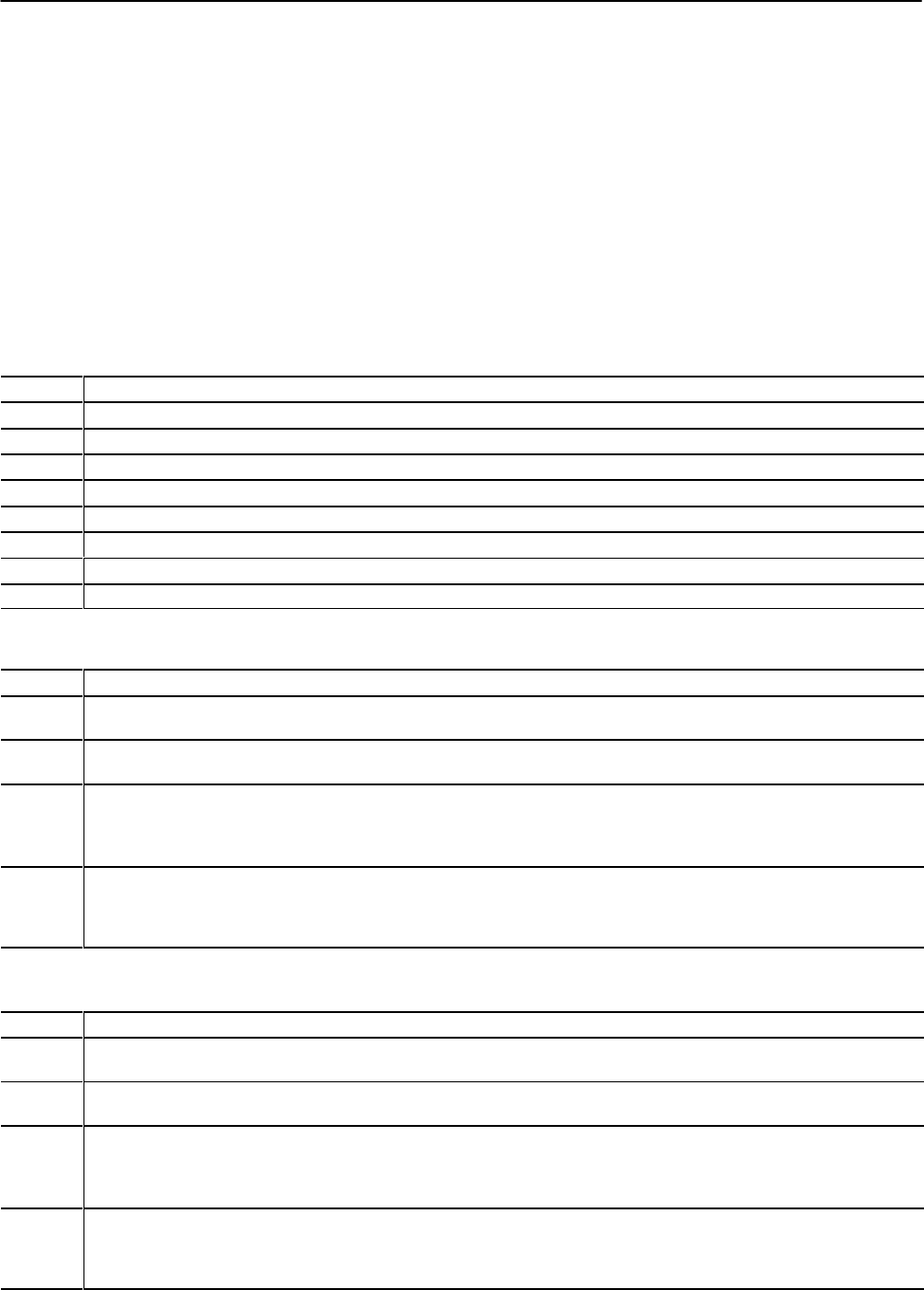

SOC

End of Profile Set-output Values

When the module completes the Second Clamp Open Profile and

OPC03-B09 is SET and SYS21-B14 is RESET, it:

• sets its outputs to the values listed below

• sets status bit SYS22-B11

• ignores SYS22 and these values and gives output control to the

Ejector Profile if SYS21-B14 is SET

• uses ramp rates SOC17 - 32 when changing outputs to these value

Use these values for pulling cores if applied before starting the Third

Clamp Open Profile.

Word Description

SOC33 Output #1 Set-output Value at End of Profile [19]

SOC34 Output #2 Set-output Value at End of Profile [19]

SOC35 Output #3 Set-output Value at End of Profile [19]

SOC36 Output #4 Set-output Value at End of Profile [19]

SOC37 Output #5 Set-output Value at End of Profile [19]

SOC38 Output #6 Set-output Value at End of Profile [19]

SOC39 Output #7 Set-output Value at End of Profile [19]

SOC40 Output #8 Set-output Value at End of Profile [19]

Pressure Control Limits

Word Description

SOC41 Pressure Minimum Control Limit [02] Minimum controllable clamp pressure attainable during any Press/Pos Second Clamp Open

Profile. The module expects this clamp pressure when setting its selected pressure valve to the %-output in SOC43.

SOC42 Pressure Maximum Control Limit [02] Maximum controllable clamp pressure attainable during any Press/Pos Second Clamp Open

Profile. The module expects this clamp pressure when setting its selected pressure valve to the %-output in SOC44.

SOC43 Selected Pressure Valve Output for Minimum [19] 0% CV output percentage that the module uses to drive the selected pressure

valve during any Press/Pos Second Clamp Open Profile. The module expects a pressure equal to SOC41 when setting the selected

pressure valve to this %-output during profile execution. The Press/Pos Second Clamp Open Profile will be executed as a reverse-

acting algorithm if this entry is greater than SOC44.

SOC44 Selected Pressure Valve Output for Maximum [19] 100% CV output percentage that the module uses to drive the selected pressure

valve during any Press/Pos Second Clamp Open Profile. The module expects a pressure equal to SOC42 when setting the selected

pressure valve to this %-output during profile execution. The Press/Pos Second Clamp Open Profile will be executed as a reverse-

acting algorithm if this entry is less than SOC43.

Velocity Control Limits

Word Description

SOC45 Velocity Minimum Control Limit [08] Minimum controllable clamp velocity attainable during any Vel/Pos Second Clamp Open Profile.

The module expects this clamp velocity when setting its selected velocity valve to the %-output in SOC47.

SOC46 Velocity Maximum Control Limit [08] Maximum controllable clamp velocity attainable during any Vel/Pos Second Clamp Open Profi-

le. The module expects this clamp velocity when setting its selected velocity valve to the %-output in SOC48.

SOC47 Selected Velocity Valve Output for Minimum [19] 0% CV output percentage that the module uses to drive the selected velocity valve

during any Vel/Pos Second Clamp Open Profile. The module expects a velocity equal to SOC45 when setting the selected velocity

valve to this %-output during profile execution. The Vel/Pos Second Clamp Open Profile will be executed as a reverse-acting algo-

rithm if this entry is greater than SOC48.

SOC48 Selected Velocity Valve Output for Maximum [19] 100% CV output percentage that the module uses to drive the selected velocity

valve during any Vel/Pos Second Clamp Open Profile. The module expects a velocity equal to SOC46 when setting the selected

velocity valve to this %-output during profile execution. The Vel/Pos Second Clamp Open Profile will be executed as a reverse-act-

ing algorithm if this entry is less than SOC47.