User Manual

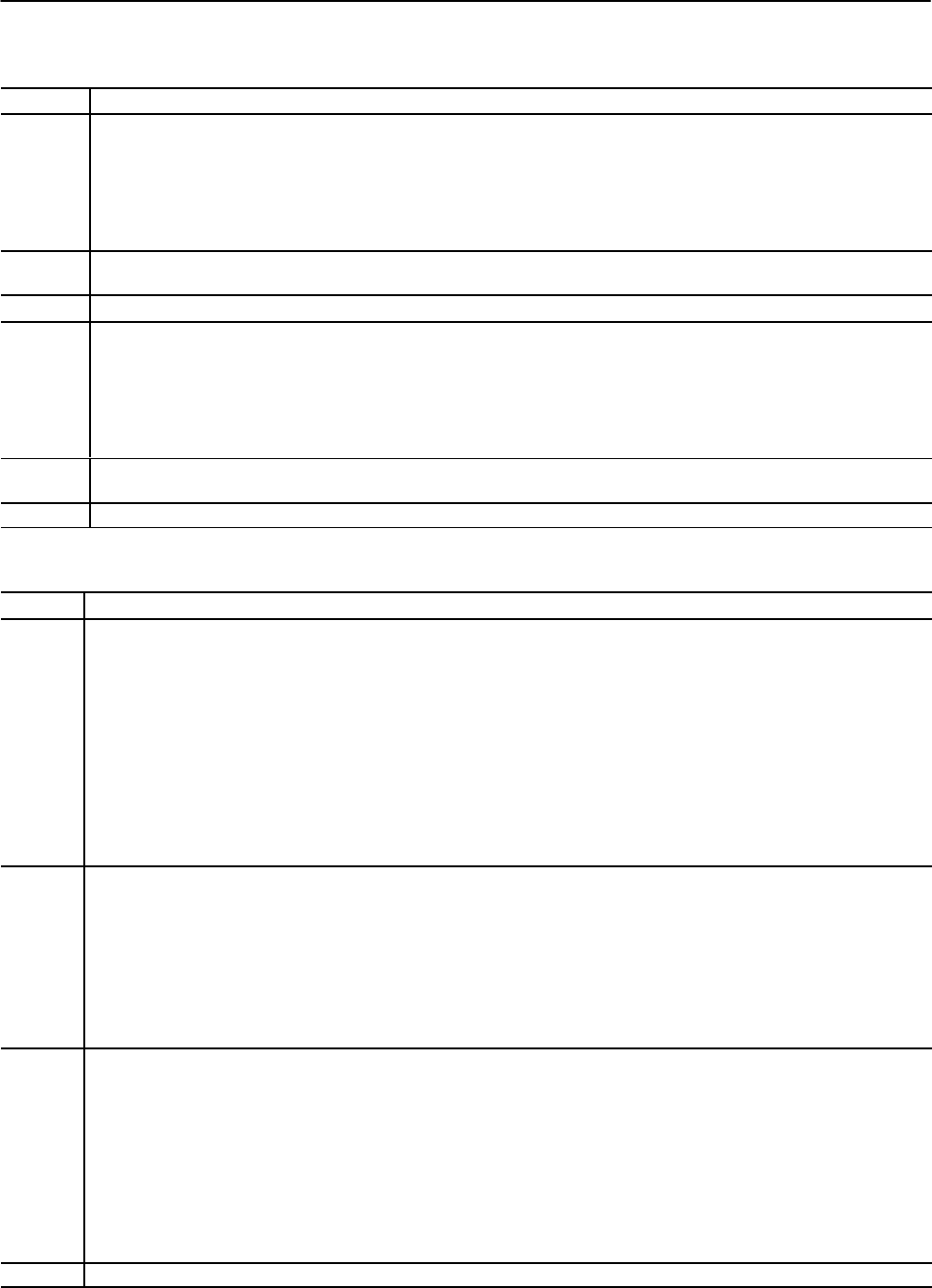

Table Of Contents

- 1771-6.5.88, Plastic Molding Module Reference Manual

- Summary of Changes

- Table of Contents

- Preface

- 1 - Abbreviated Command and Status Blocks

- Chapter Contents

- CLC - Clamp and Eject ERC Values Block

- CPC - Clamp Close Profile Block

- DYC - Dynamic Command Block

- EAC - Ejector Advance Configuration Block

- EPC - Ejector Profile Block

- ERC - Ejector Retract Configuration Block

- FCC - First Clamp Close Configuration Block

- FOC - First Clamp Open Configuration Block

- HDC - Hold Configuration Block

- HPC - Pack/Hold Profile Block

- INC - Injection Configuration Block

- IPC - Injection Profile Block

- JGC - Jog Configuration Block

- LPC - Clamp Low Pressure Close Configuration Block

- MCC - Module Configuration Command Block

- OPC - Clamp Open Profile Block

- OSC - Clamp Open Slow Configuration Block

- PKC - Pack Configuration Block

- PLC - Plastication Configuration Block

- PPC - Plastication Profile Block

- PRC - Pre-decompression Configuration Block

- PSC - Post- decompression Configuration Block

- PTC - Process Trace Configuration Block

- RLC - Inject ERC Values Block

- SCC - Second Clamp Close Configuration Block

- SOC - Second Clamp Open Configuration Block

- TCC - Third Clamp Close Configuration Block

- TOC - Third Clamp Open Configuration Block

- CLS - Clamp and Eject ERC Values Status Block

- CPS - Clamp Close Profiles Status Block

- EPS - Ejector Profile Status Block

- HPS - Pack/Hold Profile Status Block

- IPS - Injection Profile Status Block

- OPS - Clamp Open Profiles Status Block

- PPS - Plastication Profile Status Block

- PTS - Process Trace Status Block

- RLS - Inject ERC Values Status Block

- SYS - System Status Block

- 2 - Command Word/Bit Descriptions

- Alphabetical List of Command Blocks and Block ID Codes

- List of Data Words

- Engineering Units

- Data Blocks Require I/O Configuration

- Data Blocks for System Control

- Data Blocks for Controlling Ram (Screw) Position

- Data Blocks for Controlling Clamp Position

- Data Blocks for Controlling Ejector Position

- Sensors Required

- CLC CLC - Clamp and Eject ERC Values Block

- CPC - Clamp Close Profile Block

- DYC DYC - Dynamic Command Block

- EAC - Ejector Advance Configuration Block

- EPC - Ejector Profile Block

- ERC - Ejector Retract Configuration Block

- FCC - First Clamp Close Configuration Block

- FOC - First Clamp Open Configuration Block

- HDC - Hold Configuration Block

- HPC - Pack/Hold Profile Block

- INC - Injection Configuration Block

- IPC - Injection Profile Block

- JGC - Jog Configuration Block

- LPC - Clamp Low Pressure Close Configuration Block

- MCC - Module Configuration Command Block

- OPC - Clamp Open Profile Block

- OSC - Clamp Open Slow Configuration Block

- PKC - Pack Configuration Block

- PLC Plastication Configuration Command Block (PLC)

- PPC - Plastication Profile Block

- PRC - Pre-decompression Configuration Block

- PSC - Post-decompression Configuration Block

- PTC - Process Trace Configuration Block

- RLC - Inject ERC Values Block

- SCC - Second Clamp Close Configuration Block

- SOC - Second Clamp Open Configuration Block

- TCC - Third Clamp Close Configuration Block

- TOC - Third Clamp Open Configuration Block

- 3 - Word/Bit Descriptions

- List of Status Blocks and Block ID Codes

- List of Data Words

- Data Blocks Require I/O Configuration

- Engineering Units

- Status Block for Reporting System Status

- Status Blocks for Reporting Ram (Screw) Position

- Status Blocks for Reporting Clamp Position

- Status Blocks for Reporting Ejector Position

- CLS - Clamp and Eject ERC Values Status Block

- CPS - Clamp Close Profiles Status Block

- EPS - Ejector Profile Status Block

- HPS - Pack/Hold Profile Status Block

- IPS ú Injection Profile Status Block

- OPS - Clamp Open Profiles Status Block

- PPS - Plastication Profile Status Block

- PTS - Process Trace Status Block

- RLS - Inject ERC Values Status Block

- SYS - System Status Block

- 4 - Programming Error Codes

- 5 - Module Specifications

- 6 - Calibration Instructions

- A - Single transfer for Reporting Ejector Status

- Back cover

2–78 Command Word/Bit Descriptions

Publication

1771-6.5.88 – July 1997

Notes: 1. For [ ] engineering units, see page 3.

2. When using the Inject/Clamp/Eject mode, all pressure readings are system pressure at input 2, except where noted.

Clamp Open Slow Profile Setpoints

Word Description

OPC36 Segment 1 Velocity Setpoint [07] or [08]

if: then the module:

you select Vel/Pos profile execution controls clamp open speed to this setpoint after starting the Clamp Open Slow Profile

until clamp position reaches the smaller of non-zero OPC38 or OPC62

OPC03-B14 is RESET reads this parameter in percent velocity

OPC03-B14 is SET reads it in in.(mm)/s

OPC37 Segment 1 Pressure Setpoint [02] If you select Press/Pos profile execution, the module controls clamp open pressure to this set-

point after starting the Clamp Open Slow Profile until clamp position reaches the smaller of non-zero OPC38 or OPC62.

OPC38 End of Segment 1 Position Setpoint [14]

OPC39 Segment 2 Velocity Setpoint [07] or [08]

if: then the module:

you select Vel/Pos profile execution controls clamp open speed to this setpoint from the clamp position OPC38 until clamp

position reaches OPC62

OPC03-B14 is RESET reads this parameter in percent velocity

OPC03-B14 is SET reads it in in.(mm)/s

OPC40 Segment 2 Pressure Setpoint [02] If you select Press/Pos profile execution, the module controls clamp open pressure to this set-

point from the clamp position OPC38 until clamp position reaches OPC62.

OPC41 - 60 Open

Critical Process Setpoints

Word Description

OPC61 Start Clamp Open Slow Position Setpoint [14] The module uses this clamp position as protection against running a Clamp Open

Profile into the Open Slow Zone. If this position is reached while the module is executing any of the first three Clamp Open Profiles,

the module immediately terminates the ongoing profile and checks the state of OPC03-B11.

if this overrun Bit: then the module:

is RESET immediately begins the Clamp Open Slow Profile

is SET and SYS21-B14 is RESET sets its outputs to zero

is SET and SYS21-B14 is SET gives output control to the Ejector Profile

is less than or equal to clamp position sets master status bit SYS03-B06

reaches the Open Slow Zone while sets alarm status bit SYS07-B07

executing one of the first three Clamp

Open Profiles

OPC62 Mold Open Position Setpoint [14]

The module uses this clamp position as the End of Open Slow position setpoint.

if: then the module:

this position is reached while the module immediately terminates Clamp Open Slow Profile and

is executing the Clamp OpenSlow Profile

SYS21-B14 is RESET sets outputs to values OSC33 - OSC40

SYS21-B14 is SET gives output control to the Ejector Profile

clamp position equals or exceeds this entry sets master status bit SYS03-B07

OPC63 Mold Open Dwell Timer Preset [21]

When the module starts its internal Mold Open Dwell Timer (see OPC03-B15), it:

S

sets master status bit SYS03-B09

S

reports the accumulated value of the timer in SYS59

When the Mold Open Dwell Timer accumulated value in SYS59 equals this entry, the module:

S

resets master status bit SYS03-B09

S

stops accumulating time in SYS59

If it receives an F-to-T transition of any new action execution command except DYC02-B14 (Execute Ejector Profile), the module:

S

resets master status bit SYS03-B09

S

resets SYS59 to zero

OPC64 Open