User Manual

Table Of Contents

- 1771-6.5.88, Plastic Molding Module Reference Manual

- Summary of Changes

- Table of Contents

- Preface

- 1 - Abbreviated Command and Status Blocks

- Chapter Contents

- CLC - Clamp and Eject ERC Values Block

- CPC - Clamp Close Profile Block

- DYC - Dynamic Command Block

- EAC - Ejector Advance Configuration Block

- EPC - Ejector Profile Block

- ERC - Ejector Retract Configuration Block

- FCC - First Clamp Close Configuration Block

- FOC - First Clamp Open Configuration Block

- HDC - Hold Configuration Block

- HPC - Pack/Hold Profile Block

- INC - Injection Configuration Block

- IPC - Injection Profile Block

- JGC - Jog Configuration Block

- LPC - Clamp Low Pressure Close Configuration Block

- MCC - Module Configuration Command Block

- OPC - Clamp Open Profile Block

- OSC - Clamp Open Slow Configuration Block

- PKC - Pack Configuration Block

- PLC - Plastication Configuration Block

- PPC - Plastication Profile Block

- PRC - Pre-decompression Configuration Block

- PSC - Post- decompression Configuration Block

- PTC - Process Trace Configuration Block

- RLC - Inject ERC Values Block

- SCC - Second Clamp Close Configuration Block

- SOC - Second Clamp Open Configuration Block

- TCC - Third Clamp Close Configuration Block

- TOC - Third Clamp Open Configuration Block

- CLS - Clamp and Eject ERC Values Status Block

- CPS - Clamp Close Profiles Status Block

- EPS - Ejector Profile Status Block

- HPS - Pack/Hold Profile Status Block

- IPS - Injection Profile Status Block

- OPS - Clamp Open Profiles Status Block

- PPS - Plastication Profile Status Block

- PTS - Process Trace Status Block

- RLS - Inject ERC Values Status Block

- SYS - System Status Block

- 2 - Command Word/Bit Descriptions

- Alphabetical List of Command Blocks and Block ID Codes

- List of Data Words

- Engineering Units

- Data Blocks Require I/O Configuration

- Data Blocks for System Control

- Data Blocks for Controlling Ram (Screw) Position

- Data Blocks for Controlling Clamp Position

- Data Blocks for Controlling Ejector Position

- Sensors Required

- CLC CLC - Clamp and Eject ERC Values Block

- CPC - Clamp Close Profile Block

- DYC DYC - Dynamic Command Block

- EAC - Ejector Advance Configuration Block

- EPC - Ejector Profile Block

- ERC - Ejector Retract Configuration Block

- FCC - First Clamp Close Configuration Block

- FOC - First Clamp Open Configuration Block

- HDC - Hold Configuration Block

- HPC - Pack/Hold Profile Block

- INC - Injection Configuration Block

- IPC - Injection Profile Block

- JGC - Jog Configuration Block

- LPC - Clamp Low Pressure Close Configuration Block

- MCC - Module Configuration Command Block

- OPC - Clamp Open Profile Block

- OSC - Clamp Open Slow Configuration Block

- PKC - Pack Configuration Block

- PLC Plastication Configuration Command Block (PLC)

- PPC - Plastication Profile Block

- PRC - Pre-decompression Configuration Block

- PSC - Post-decompression Configuration Block

- PTC - Process Trace Configuration Block

- RLC - Inject ERC Values Block

- SCC - Second Clamp Close Configuration Block

- SOC - Second Clamp Open Configuration Block

- TCC - Third Clamp Close Configuration Block

- TOC - Third Clamp Open Configuration Block

- 3 - Word/Bit Descriptions

- List of Status Blocks and Block ID Codes

- List of Data Words

- Data Blocks Require I/O Configuration

- Engineering Units

- Status Block for Reporting System Status

- Status Blocks for Reporting Ram (Screw) Position

- Status Blocks for Reporting Clamp Position

- Status Blocks for Reporting Ejector Position

- CLS - Clamp and Eject ERC Values Status Block

- CPS - Clamp Close Profiles Status Block

- EPS - Ejector Profile Status Block

- HPS - Pack/Hold Profile Status Block

- IPS ú Injection Profile Status Block

- OPS - Clamp Open Profiles Status Block

- PPS - Plastication Profile Status Block

- PTS - Process Trace Status Block

- RLS - Inject ERC Values Status Block

- SYS - System Status Block

- 4 - Programming Error Codes

- 5 - Module Specifications

- 6 - Calibration Instructions

- A - Single transfer for Reporting Ejector Status

- Back cover

2–66 Command Word/Bit Descriptions

Publication

1771-6.5.88 – July 1997

Notes: 1. For [ ] engineering units, see page 3.

2. When using the Inject/Clamp/Eject mode, all pressure readings are system pressure at input 2, except where noted.

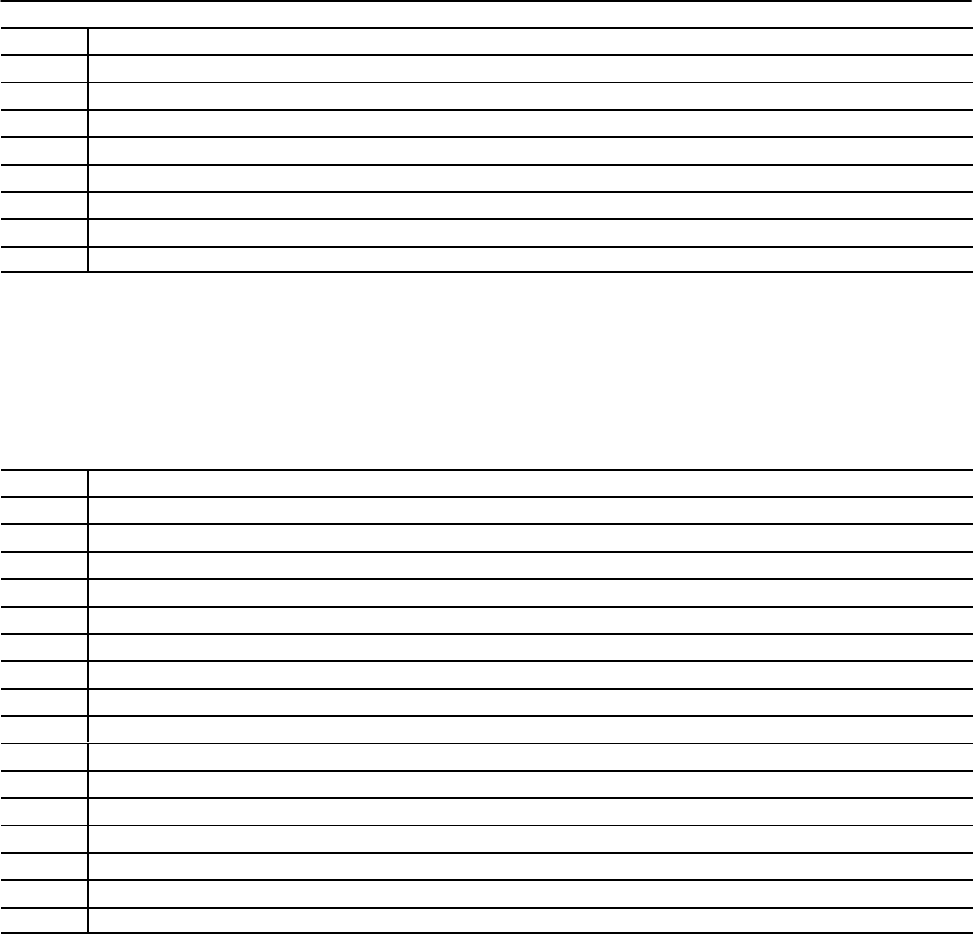

Word

Description

LPC09 Output #1 Set-output Value during Profile [19]

LPC10 Output #2 Set-output Value during Profile [19]

LPC11 Output #3 Set-output Value during Profile [19]

LPC12 Output #4 Set-output Value during Profile [19]

LPC13 Output #5 Set-output Value during Profile [19]

LPC14 Output #6 Set-output Value during Profile [19]

LPC15 Output #7 Set-output Value during Profile [19]

LPC16 Output #8 Set-output Value during Profile [19]

Output Ramp Rates

The module uses the following ramp rates when moving its outputs

from setpoint to setpoint during the Clamp Low Pressure Close

Profile. The module interprets a ramp rate entry of zero as a step

function ramp (ramp disable).

Word Description

LPC17 Output #1 Acceleration Ramp Rate during Profile [20]

LPC18 Output #2 Acceleration Ramp Rate during Profile [20]

LPC19 Output #3 Acceleration Ramp Rate during Profile [20]

LPC20 Output #4 Acceleration Ramp Rate during Profile [20]

LPC21 Output #5 Acceleration Ramp Rate during Profile [20]

LPC22 Output #6 Acceleration Ramp Rate during Profile [20]

LPC23 Output #7 Acceleration Ramp Rate during Profile [20]

LPC24 Output #8 Acceleration Ramp Rate during Profile [20]

LPC25 Output #1 Deceleration Ramp Rate during Profile [20]

LPC26 Output #2 Deceleration Ramp Rate during Profile [20]

LPC27 Output #3 Deceleration Ramp Rate during Profile [20]

LPC28 Output #4 Deceleration Ramp Rate during Profile [20]

LPC29 Output #5 Deceleration Ramp Rate during Profile [20]

LPC30 Output #6 Deceleration Ramp Rate during Profile [20]

LPC31 Output #7 Deceleration Ramp Rate during Profile [20]

LPC32 Output #8 Deceleration Ramp Rate during Profile [20]

End of Profile Set-output Values

When the module completes the Clamp Low Pressure Close Profile, it:

• sets its outputs to the following values

• sets status bit SYS22-B03

• uses ramp rates LPC17 - 32 when changing outputs to these values

Use these values to apply tonnage to the mold before starting the

Injection Profile, or for setting cores if applied before starting the

Injection Profile.