User Manual

Table Of Contents

- 1771-6.5.88, Plastic Molding Module Reference Manual

- Summary of Changes

- Table of Contents

- Preface

- 1 - Abbreviated Command and Status Blocks

- Chapter Contents

- CLC - Clamp and Eject ERC Values Block

- CPC - Clamp Close Profile Block

- DYC - Dynamic Command Block

- EAC - Ejector Advance Configuration Block

- EPC - Ejector Profile Block

- ERC - Ejector Retract Configuration Block

- FCC - First Clamp Close Configuration Block

- FOC - First Clamp Open Configuration Block

- HDC - Hold Configuration Block

- HPC - Pack/Hold Profile Block

- INC - Injection Configuration Block

- IPC - Injection Profile Block

- JGC - Jog Configuration Block

- LPC - Clamp Low Pressure Close Configuration Block

- MCC - Module Configuration Command Block

- OPC - Clamp Open Profile Block

- OSC - Clamp Open Slow Configuration Block

- PKC - Pack Configuration Block

- PLC - Plastication Configuration Block

- PPC - Plastication Profile Block

- PRC - Pre-decompression Configuration Block

- PSC - Post- decompression Configuration Block

- PTC - Process Trace Configuration Block

- RLC - Inject ERC Values Block

- SCC - Second Clamp Close Configuration Block

- SOC - Second Clamp Open Configuration Block

- TCC - Third Clamp Close Configuration Block

- TOC - Third Clamp Open Configuration Block

- CLS - Clamp and Eject ERC Values Status Block

- CPS - Clamp Close Profiles Status Block

- EPS - Ejector Profile Status Block

- HPS - Pack/Hold Profile Status Block

- IPS - Injection Profile Status Block

- OPS - Clamp Open Profiles Status Block

- PPS - Plastication Profile Status Block

- PTS - Process Trace Status Block

- RLS - Inject ERC Values Status Block

- SYS - System Status Block

- 2 - Command Word/Bit Descriptions

- Alphabetical List of Command Blocks and Block ID Codes

- List of Data Words

- Engineering Units

- Data Blocks Require I/O Configuration

- Data Blocks for System Control

- Data Blocks for Controlling Ram (Screw) Position

- Data Blocks for Controlling Clamp Position

- Data Blocks for Controlling Ejector Position

- Sensors Required

- CLC CLC - Clamp and Eject ERC Values Block

- CPC - Clamp Close Profile Block

- DYC DYC - Dynamic Command Block

- EAC - Ejector Advance Configuration Block

- EPC - Ejector Profile Block

- ERC - Ejector Retract Configuration Block

- FCC - First Clamp Close Configuration Block

- FOC - First Clamp Open Configuration Block

- HDC - Hold Configuration Block

- HPC - Pack/Hold Profile Block

- INC - Injection Configuration Block

- IPC - Injection Profile Block

- JGC - Jog Configuration Block

- LPC - Clamp Low Pressure Close Configuration Block

- MCC - Module Configuration Command Block

- OPC - Clamp Open Profile Block

- OSC - Clamp Open Slow Configuration Block

- PKC - Pack Configuration Block

- PLC Plastication Configuration Command Block (PLC)

- PPC - Plastication Profile Block

- PRC - Pre-decompression Configuration Block

- PSC - Post-decompression Configuration Block

- PTC - Process Trace Configuration Block

- RLC - Inject ERC Values Block

- SCC - Second Clamp Close Configuration Block

- SOC - Second Clamp Open Configuration Block

- TCC - Third Clamp Close Configuration Block

- TOC - Third Clamp Open Configuration Block

- 3 - Word/Bit Descriptions

- List of Status Blocks and Block ID Codes

- List of Data Words

- Data Blocks Require I/O Configuration

- Engineering Units

- Status Block for Reporting System Status

- Status Blocks for Reporting Ram (Screw) Position

- Status Blocks for Reporting Clamp Position

- Status Blocks for Reporting Ejector Position

- CLS - Clamp and Eject ERC Values Status Block

- CPS - Clamp Close Profiles Status Block

- EPS - Ejector Profile Status Block

- HPS - Pack/Hold Profile Status Block

- IPS ú Injection Profile Status Block

- OPS - Clamp Open Profiles Status Block

- PPS - Plastication Profile Status Block

- PTS - Process Trace Status Block

- RLS - Inject ERC Values Status Block

- SYS - System Status Block

- 4 - Programming Error Codes

- 5 - Module Specifications

- 6 - Calibration Instructions

- A - Single transfer for Reporting Ejector Status

- Back cover

Summary of Changes

Publication

1771-6.5.88 – July 1997

This manual is a revision of the November 1992 edition for module

upgrade to series C, revision E and series D, revision A.

It contains information on the following enhancements:

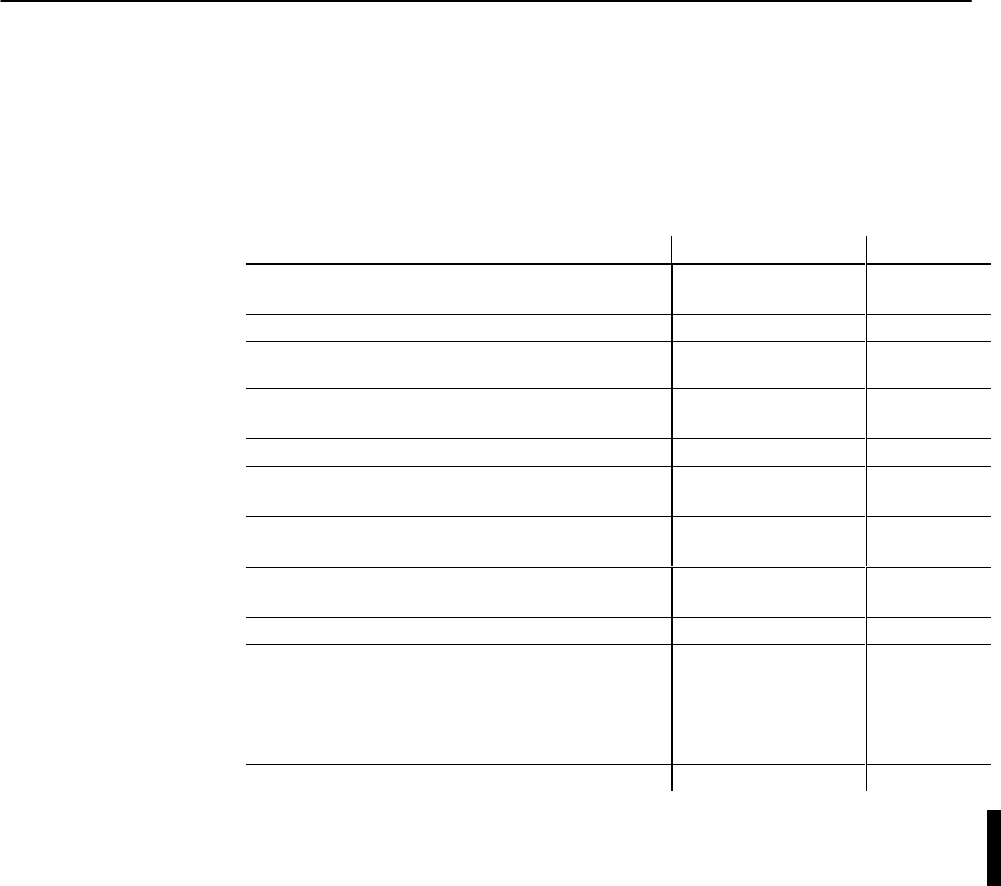

For this enhancement: Refer to: On page:

Pro-set 700 Software data table addresses

(same as Pro-Set 600 addresses)

chapter 1 throughout

time delay to avoid nuisance alarms MCC64 2-73

more accurate end-of-post-decompression position

(now includes shot size (PPC61) + cushion size (PPC62)

PSC05 2-93

adjust the stop point to an offset rather than 0V or 4mA

MCC05-08, and

MCC error codes 405-408

2-69

4-4

override loss-of-sensor protection MCC02-B08 thru B15 2-68

loss-of-sensor protection with indication by system status bits

SYS08-B00 thru B07

SYS12-B00 thru B07

3-33

3-35

added a tolerance with hysteresis of 0.05” (0.5mm) to mold

open and ejector retract positions indicated by their status bits

SYS03-B07 for OPC62

SYS03-B15 for EPC60

3-27

3-28

detect and report double-command-bit error in DYC01,

and in DYC02

SYS23

SYS24

3-46

you can enter maximum travel limits as position setpoints chapter 4, error codes throughout

starting in Series D

added process trace to store traces of machine performance

(for Process Trace User Manual, see publication 6500-6.5.21)

configuration block PTC

status block PTS

command bits in DYC

status bits in SYS

PTC error codes

2-95 thru 2-96

3-22 thru 3-24

2-23 and 2-24

3-39, 40, 41, 42

4-57

single-transfer programming to report ejector status appendix A A-1

To help you find this new information, we added change bars as

shown to the right.

We have rearranged the format of this manual for quicker reference

and easier usage. The most prominent new feature is the order in

which we present command and status blocks. They are now in

alphabetical order.

New Information

New Format