supporting Sequence of Events

Table Of Contents

- 1732E-UM002A-EN-E 1732E EtherNet/IP ArmorBlock Supporting Sequence of Events User Manual

- Important User Information

- Table of Contents

- Preface

- Chapter 1 - About 1732E ArmorBlock Modules

- Chapter 2 - Module Overview

- Chapter 3 - Use the Module in an ArmorBlock System

- Chapter 4 - Install Your Module

- Chapter 5 - Configure the Module for Your EtherNet/IP Network

- Chapter 6 - Configure the Module Using RSLogix 5000

- Introduction

- Set Up the Hardware

- Create the Example Application

- Configure Your I/O Module

- Overview of the Configuration Process

- Add a New Bridge and Module to Your RSLogix 5000 Project

- Use the Default Configuration

- Change the Default Configuration

- Download Your Configuration

- Edit Your Configuration

- Access Module Data in RSLogix 5000

- Configure RSLogix 5000 and the 1756-EN2T Communication Module for CIP Sync

- Chapter Summary and What’s Next

- Chapter 7 - Module Features

- Introduction

- Determine Module Compatibility

- Module Features That Can Be Configured

- Chapter Summary and What’s Next

- Chapter 8 - Using the Module

- Chapter 9 - Interpret Status Indicators

- Chapter 10 - Troubleshoot the Module

- Appendix A - ArmorBlock 2 Port Ethernet Module Specifications

- Appendix B - Module Tags

- Appendix C - 1732E EtherNet/IP ArmorBlock Supporting Sequence of Events Data Tables

- Appendix D - Connect to Networks via Ethernet Interface

- Appendix E - 1732E ArmorBlock I/O Embedded Web Server

- Glossary

- Index

- How Are We Doing?

- Back Cover

Publication 1732E-UM002A-EN-P - March 2010

2 About 1732E ArmorBlock Modules

Contact Rockwell Automation if you need software or firmware upgrades to

use this equipment.

For a complete ControlLogix compatibility matrix, see publication IA-AT003

.

Use of the Common

Industrial Protocol (CIP)

The 1732E-IB16M12SOEDR uses the Common Industrial Protocol (CIP).

CIP is the application layer protocol specified for EtherNet/IP, the Ethernet

Industrial Protocol, as well as for ControlNet and DeviceNet. It is a

message-based protocol that implements a relative path to send a message

from the “producing” device in a system to the “consuming” devices.

The producing device contains the path information that steers the message

along the proper route to reach its consumers. Because the producing device

holds this information, other devices along the path simply pass this

information; they do not need to store it.

This has two significant benefits:

• You do not need to configure routing tables in the bridging modules,

which greatly simplifies maintenance and module replacement.

• You maintain full control over the route taken by each message, which

enables you to select alternative paths for the same end device.

Understand the

Producer/Consumer Model

The CIP “producer/consumer” networking model replaces the old

source/destination (“master/slave”) model. The producer/consumer model

reduces network traffic and increases speed of transmission. In traditional I/O

systems, controllers poll input modules to obtain their input status. In the CIP

system, input modules are not polled by a controller. Instead, they produce

their data either upon a change of state (COS) or periodically. The frequency

of update depends upon the options chosen during configuration and where

on the network the input module resides. The input module, therefore, is a

producer of input data and the controller is a consumer of the data.

The controller can also produce data for other controllers to consume. The

produced and consumed data is accessible by multiple controllers and other

devices over the EtherNet/IP network. This data exchange conforms to the

producer/consumer model.

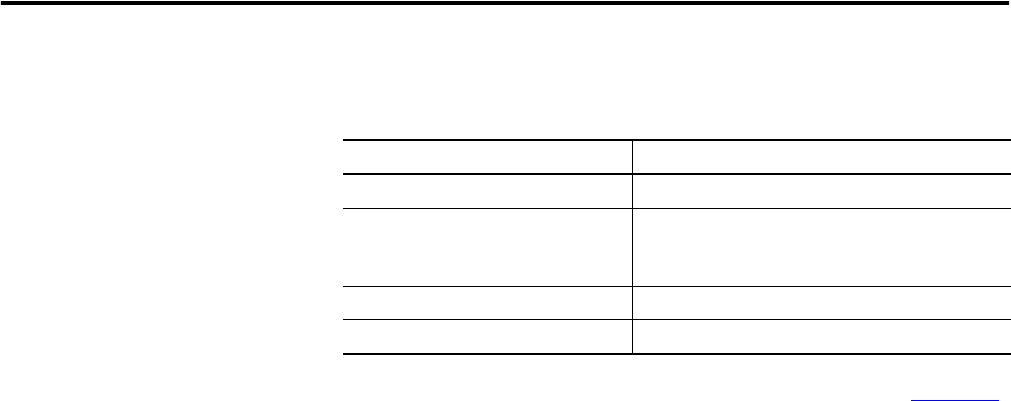

Product Firmware Version / Software Release

1732E-IB16M12SOEDR Firmware rev. 1.6 or later

1756-EN2T or 1756-EN2TR module 2.3 (or later version of major revision 2) when

using RSLogix 5000 v17

3.x version when using RSLogix 5000 v18 or later

RSLogix 5000 software 17 or later

RSLinx software 2.56 or later