Manual

Table Of Contents

- 161 Appx_a.pdf

- New 161_bkcvr.pdf

- 161 Chptr_3.pdf

- Programming Keypad

- Programming Examples

- Initial Power Up

- Scrolling through parameter groups

- Operation of the Drive via the Fixed Keypad

- Note: The factory default settings for the “U” version drive is three wire control (PC03 is set t...

- Note: The direction of rotation is controlled by PF04 - [Start Key Direction]. Refer to page 22 o...

- Activating the Speed Pot on the Keypad

- Parameter A01-[Frequency Command Select] is used to select the source of the frequency command.

- Note: The output frequency of the Bulletin 161 can also be controlled digitally from the keypad b...

- Note: If a digital input is set as 27 (UP) or 28 (DWN), when activated these inputs will also cha...

- Restoring Factory Defaults

- Parameter Descriptions

- 161 Chptr_2.pdf

- 161 Chptr_3.pdf

- Programming Keypad

- Programming Examples

- Initial Power Up

- Scrolling through parameter groups

- Operation of the Drive via the Fixed Keypad

- Note: The factory default settings for the “U” version drive is three wire control (PC03 is set t...

- Note: The direction of rotation is controlled by PF04 - [Start Key Direction]. Refer to page 22 o...

- Activating the Speed Pot on the Keypad

- Parameter A01-[Frequency Command Select] is used to select the source of the frequency command.

- Note: The output frequency of the Bulletin 161 can also be controlled digitally from the keypad b...

- Note: If a digital input is set as 27 (UP) or 28 (DWN), when activated these inputs will also cha...

- Restoring Factory Defaults

- Parameter Descriptions

- 161 Chptr_2.pdf

- 161 Chptr_4.pdf

37

Faults & Troubleshooting

Other Displays

The motor does not accelerate properly. 1. Check to see that a frequency has been commanded.

2. Check to see if a preset frequency has been selected.

3. Check to see if the motor load is too high.

4. Check to see if the acceleration time is too long.

5. Check to see if manual boost and current limit are set properly.

The speed of the motor does not match the

frequency.

1. Check to see that the maximum frequency has been entered

correctly.

2. Check the rated speed of the motor and the reduction ratio of

the gear.

3. Check to see if manual boost and current limit are set properly.

4. If PID control is used, check gain adjustments.

The motor runs unstable. 1. If sudden high load changes occur, choose a drive and motor

with higher ratings or reduce the load changes.

2. If resonant frequencies occur in the motor, set up skip

frequency bands.

3. If the input voltage is not constant, change the PWM carrier

frequency.

The parameters stored do not match the values

entered.

1. When the input voltage was switched off the entered values

were transferred to the power-failure safe EEPROM.

Reprogram the values and wait at least 6 seconds before

powering down.

No entries can be made. 1. Check to see if the parameter protection is activated via a

digital input setting of 15 {SFT}.

The electronic motor protection (fault E05) is

triggered.

1. Check the manual boost setting to see if it is too high.

2. Check the electronic motor protection setting to make sure that

it is correct.

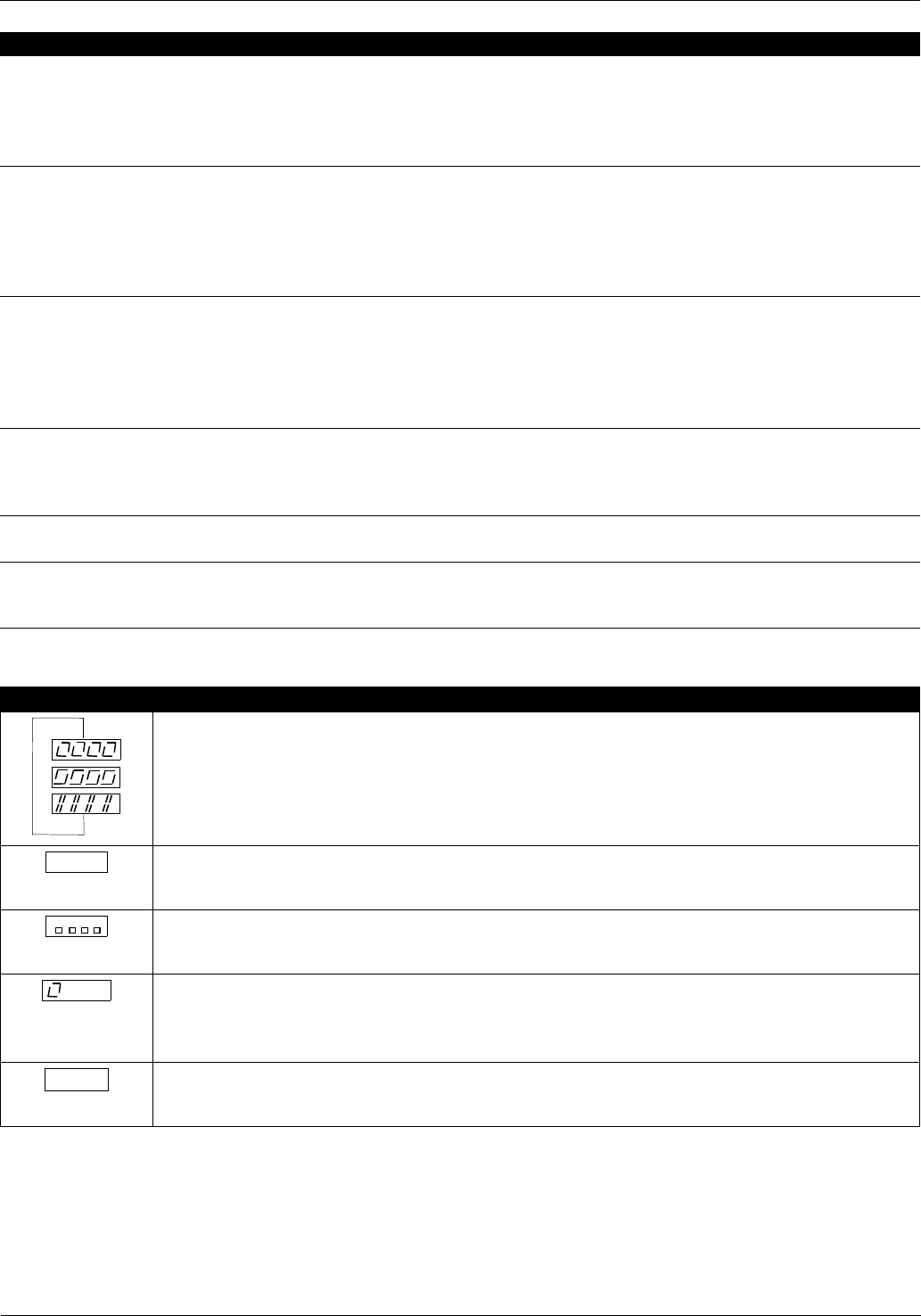

Display Description

A reset signal has been issued.

The Bulletin 161 drive is in standby mode.

Note: If motor was running when the 18 {RS} input was received, the motor will coast to a

stop.

The input voltage has been switched off.

The waiting time before automatic restart has expired (see Pb01-[Restart Mode Select] - Pb03-

[Restart time]).

The factory setting has been selected and the drive is in the initialization phase

(see Pb84-[Reset Functions], Pb85-[Factory Defaults Select]). If your drive is a K version,

parameters for the 50Hz version are loaded. If your drive is a U version, parameters for the 60 Hz

version are loaded.

No data present or the function is not active.

Problem Corrective Action

- - -

06

_ _ _