Reference Adapter for RTP Applications User Manual

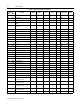

Table Of Contents

- Front Cover

- Important User Information

- Table of Contents

- Preface

- Who Should Use This Manual

- Purpose of This Manual

- Safety Precautions

- Contents of This Manual

- Related Documentation

- Information on the Intelligent Terminal System (ITS)

- Bulletin 1300 Intelligent Terminal System Documentation Set

- Allen-Bradley offers support services worldwide, with Sales/Support Offices, authorized distribut...

- Contact your local Allen-Bradley representative for:

- If you need to contact Allen-Bradley for technical assistance, please review the product and trou...

- Chapter 1

- Chapter 2

- Chapter 3

- Chapter 4

- Chapter 5

- Chapter Content

- 1. These steps should already have been performed on a custom Drive manufactured and shipped as a...

- 2. If a Drive that has already been installed is receiving a Digital Reference Adapter Board as a...

- 3. If for any reason a given Drive loses the EE memory information, it will also be necessary to ...

- 4. Should there be a need to check or download parameters to the Drive, use of the ITS device wil...

- 1. Establish Configuration Links between Drive and the Digital Reference Adapter Board.

- 2. Program Digital Reference Adapter Set-Up Parameters.

- Terminology

- Parameter Set-Up Description

- Example Start-Up Configuration (Linking)

- Digital Input/Output Set-up

- Analog Input/Output Set-up

- Configuration Links Set-up

- Chapter Content

- Chapter 6

- Introduction

- 1. Hard Faults Hard Faults are nonrecoverable. That is, the 1395 Drive must either be RESET or PO...

- 2. Soft Faults Soft Faults occur when an Adapter Board detects a condition which may result in un...

- 3. Warning Faults Conditions detected within the system that may produce Soft Faults if the condi...

- Digital Reference Fault Messages

- Adapter Troubleshooting

- Introduction

- Chapter 7

- Chapter 8

- Index

- Back Cover

Publication 1395-RTP-5.2 - September 1997

7-2 Periodic Maintenance

Guidelines for the Application, Installation and Maintenance of Solid

State Control”.

Static Sensitive Items – While performing maintenance, special

precautions must be observed in handling or touching certain static

sensitive components in the cabinet. All circuit cards can be damaged

by Electro-Static Discharge. If personnel will make contact with an

ESD sensitive component during maintenance, they must be

grounded. Grounding should be accomplished with a wrist strap

which is connected to an approved ground.

Tests & Records

Final Check Out – After maintenance or repair of industrial controls,

always test the control system for proper functioning under controlled

conditions that avoid hazards in the event of a control malfunction.

“Keep Good Maintenance Records” – This rule will be most

helpful in locating possible intermittent problems by pointing to a

particular area of recurring trouble within the overall system. Further,

good maintenance records will help reduce major costly shutdowns

by demanding the use of proper test equipment and an appropriate

inventory of spare parts. For additional information See NFPA 70B,

RECOMMENDED PRACTICE FOR ELECTRICAL EQUIPMENT

MAINTENANCE, published by the National Fire Protection

Association.

!

ATTENTION: Use of other than factory

recommended test equipment for solid state controls

may result in damage to the control or test equipment

or unintended actuation of the controlled equipment.