User Manual

65-2502RK/65-2510RK Oxygen D e tec tor • 7

Troubleshooting

The troubleshooting guide describes symptoms, probable causes, and recommended

action for problems you may encounter with th e oxygen detector.

NOTE: This troubleshooting guid e describes detector problems only. See the controller

instruction ma nual for problems you may encounter with the controller.

Replacing the Oxygen Detector

1. Tu rn off the contro ller.

2. Tu rn off power to the cont roller.

3. If the detector is installed directly on a controller, open the controller door.

If the detector is installed remotely from a controller in a junction box, remove the

junction box cover.

4. If the detector is installed directly on a controller, disconnect the detector leads from

the detector terminal strip in the controller. Note the position of the color-coded leads

as you remove them.

If the detector is installed remotely from a controller in a junction box, disconnect the

detector leads from the terminal block in the junction box. Note the position of the

color-coded leads as you remove them.

5. Unscrew the detector from the controller conduit hub or junctio n box conduit hub.

6. Guide the detector leads of the replacement detector through the controller conduit

hub or junction box conduit hub, then screw the mounting threads of the detector into

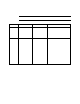

Table 2:Troubleshooting the Oxygen Detector

Condition Symptom(s) Probable Causes Recommended Action

Fail Condition • Controller indicates a

fail condition.

• The detector wiring is

disconnected or

misconnected.

• The detector is

malfunctioning.

1. Verify that the detector wiring is

correct and secure.

2. C al ib rate the detector.

3. If the fail condition continues, replace

the detector.

4. If the fail condition continues, contact

RKI for further instruction.

Slow or No

Response/

Difficult or

Unable to

Calibrate

• Detector responds

slowly or does not

respond to response

test.

• Unable to accurately

set the fresh air or

zero reading during

calibration.

• Detector requires

frequent cal ib r ati on.

Note: Under “normal”

circumstances, the

detector requ ires

calibration once every

three months .

Some applications may

require a more freque nt

calibration schedule.

• The calibration cylinder

is low, out-dated, or

defective.

• The detector is

malfunctioning.

1. Verify that the calibration cylinder

contains an adequate supply of a

fresh test sample.

2. If the calibration/response difficulties

continue, replace the detector.

3. If the calibration/response difficulties

continue, contact RKI for further

instruction.