Instruction manual

Table Of Contents

6. COMMUNICATION DATA

IMS01J04-E2

19

Continued from the previous page.

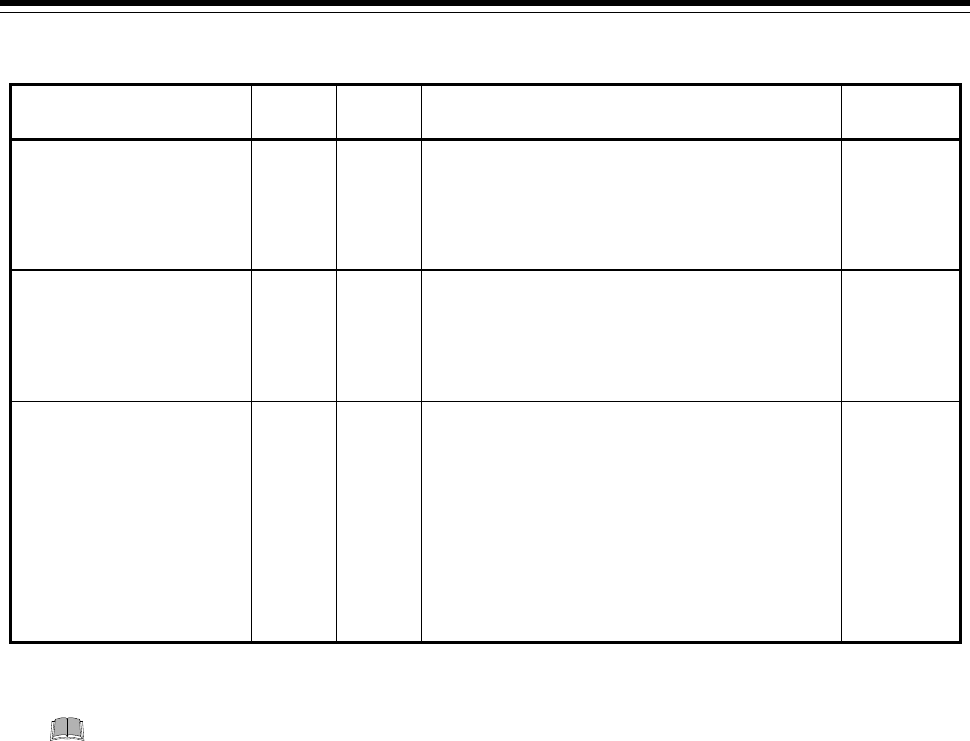

Name

Attri-

bute

Struc-

ture

Data range

Factory

set value

Integral time

[H-TIO-, H-CIO-A,

H-SIO-A]

R/W C 1 to 3600 seconds

H-TIO-,

H-CIO-A:

240

H-SIO-A:

2

Derivative time

[H-TIO-, H-CIO-A,

H-SIO-A]

R/W C 0 to 3600 seconds (0: PI action)

H-TIO-,

H-CIO-A:

60

H-SIO-A:

0

PID/AT transfer *

[H-TIO-, H-CIO-A,

H-SIO-A]

R/W C

0: PID control operation

1: AT (Autotuning) operation

The autotuning (AT) function starts its

execution with PID/AT transfer and the

request command set to “1: AT operation”

and “1: Setting,” respectively. After the

autotuning function finishes its execution,

PID/AT transfer returns to “0: PID control

operation.”

0

* Autotuning (AT) is the function which automatically measures, calculates and sets the optimum PID

constants according to the set temperature.

Caution for using the Autotuning (AT)

When a temperature change (UP and/or Down) is 1C or less per minute during

Autotuning, Autotuning may be cancelled before calculating PID values. In that case,

adjust the PID values manually. It is possible to happen when the set value is around

the ambient temperature or is close to the maximum temperature achieved by the load.

The following is the conditions necessary to carry out autotuning and the conditions which will cause

the autotuning to stop.

Conditions necessary for autotuning:

The autotuning should be executed after satisfying all of the following conditions:

Operation mode conditions:

Auto/Manual transfer Auto mode

PID/AT transfer PID control mode

Control RUN/STOP transfer Control RUN mode

The measured value (PV) is without input error range [Input error determination point (high)

Measured value (PV) Input error determination point (low)].

The output limiter high limit should be more than 0.1 % and the output limiter low limit should be

less than 99.9 %.

When operation mode is set to “Normal (Can be controlled ).”

When the autotuning is finished, the display of each channel automatically returns to “0: PID control

operation.”

Continued on the next page.