Instruction manual

Table Of Contents

6. COMMUNICATION DATA

IMS01J04-E2

15

6.2 Data Processing Precautions

With PLC communication, the maximum number of channels per unit address is 20.

Read data of unused channel and undefined address is 0.

The data type is treated as binary data with a sign and without a decimal point. For this reason,

carefully express and set the data. (excluding the TIO status)

[Example] Heat-side proportional band

Initial value of internal data: 3.0

Communication data: 30

If the data range error occurs during data setting, “Setting error” (bit 8 in the TIO status) is set to

ON in the channel where the error occurs. The SR Mini HG SYSTEM continues operation at the

present set value without updating the data.

Any attempt to write to an unused channel is not processed as an error.

The autotuning (AT) function starts its execution with PID/AT transfer and the request command

set to “1: AT operation” and “1: Setting,” respectively. After the autotuning function finishes its

execution, PID/AT transfer returns to “0: PID control operation” and thus the PID constants are

updated.

When the PLC communication status is selected by selecting the H-PCP-J module DO type

(Identifier VU), the digital output (DO) is turned on or off according to the status of

communication between the H-PCP-J module and PLC.

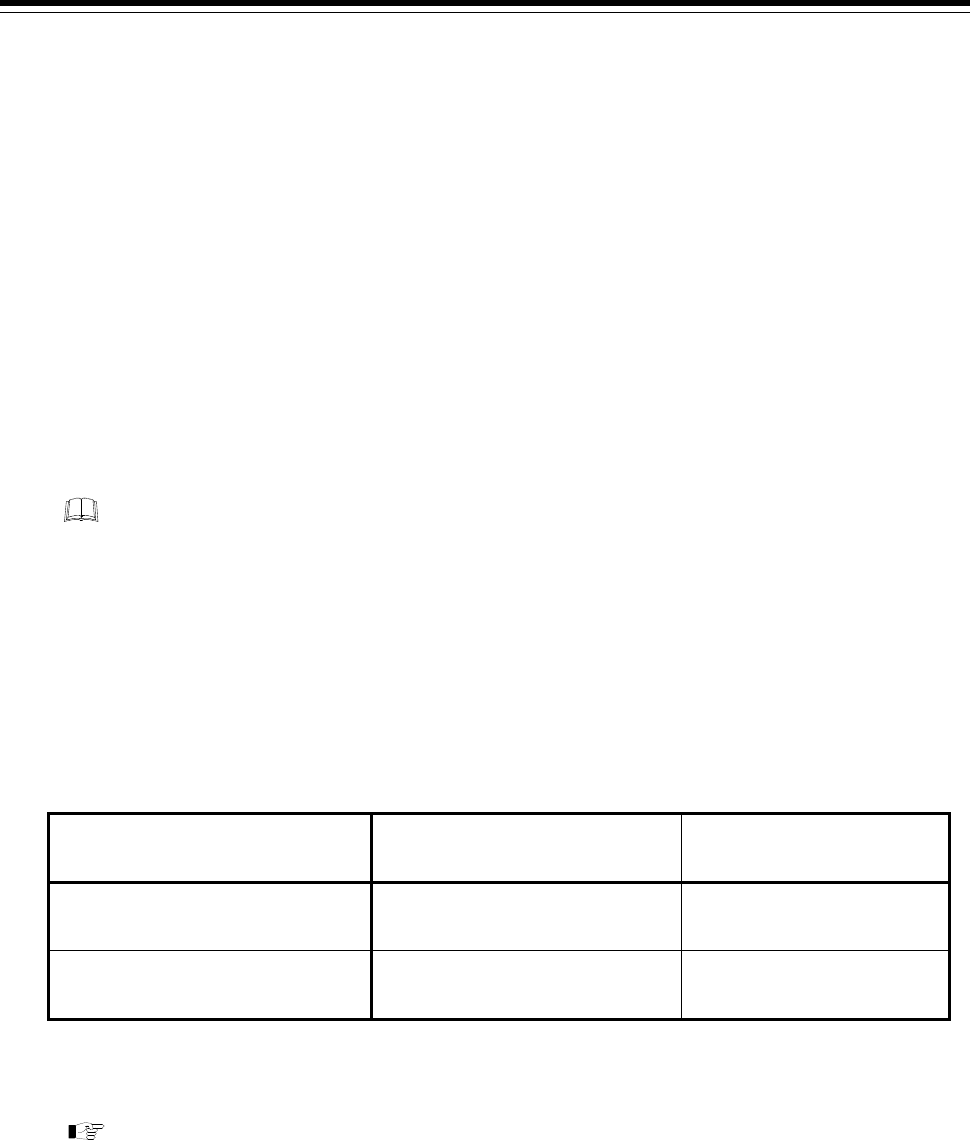

Communication error

PLC communication status

(H-PCP-J module DO)

Operation mode

When the communication is error

after the power ON immediately

OFF “1: Monitor”

When the communication is error

during operation

OFF

Same as mode before the

communication error

If communication between the H-PCP-J module and PLC is ready, the PLC communication status

(H-PCP-J module DO) is turned on to enable operation to continue.

The H-PCP-J module DO type selection (Identifier VU) is set by host communication. For

the host communication, see the Power Supply/CPU Module H-PCP-J Instruction

Manual (IMS01J02-E).